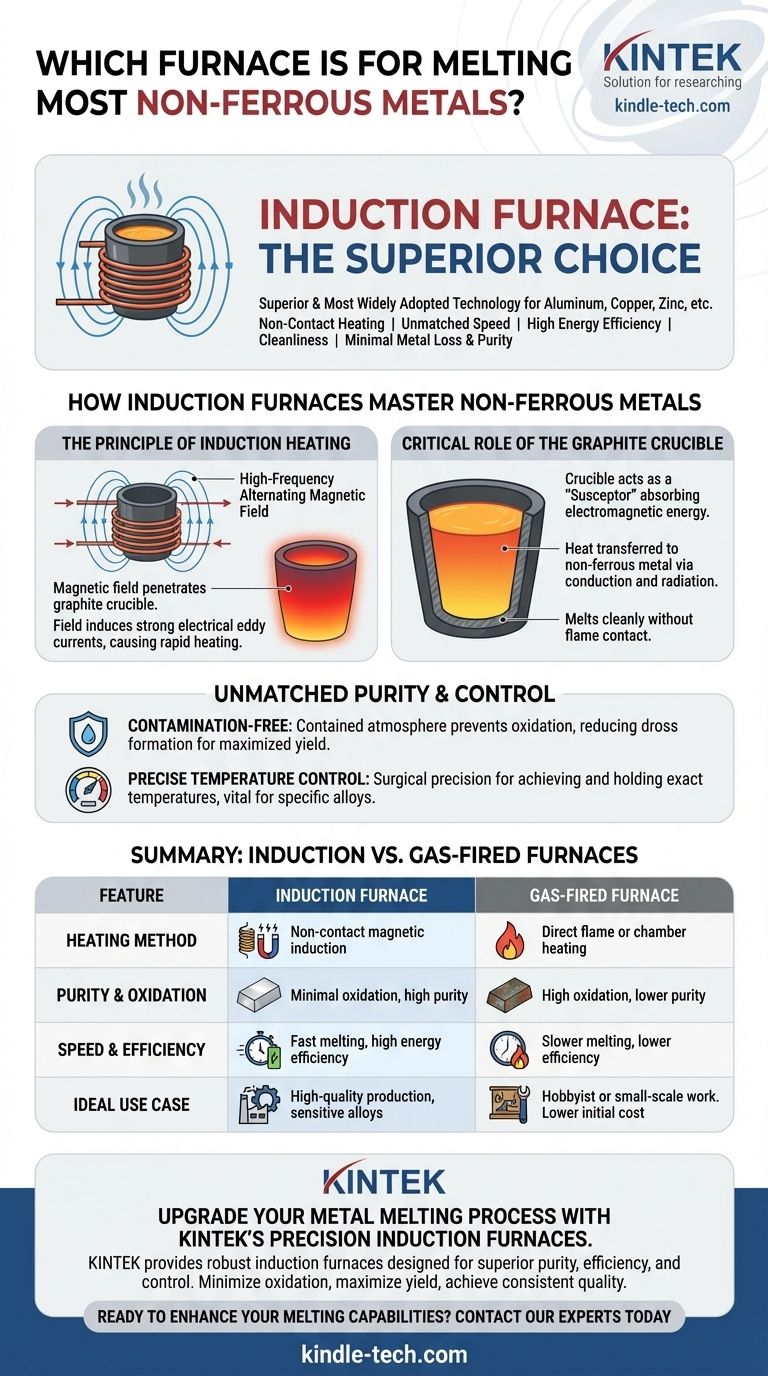

For melting most non-ferrous metals, the induction furnace is the superior and most widely adopted technology. Its method of non-contact heating provides unmatched speed, energy efficiency, and cleanliness, making it ideal for materials like aluminum, copper, and zinc where purity and minimal metal loss are critical.

The core reason for its effectiveness lies in how it works: an induction furnace uses a magnetic field to heat a graphite crucible, which in turn melts the metal inside. This indirect, controlled heating process minimizes contamination and oxidation, a common problem with traditional flame-based furnaces.

How Induction Furnaces Master Non-Ferrous Metals

To understand why induction technology is the standard for high-quality non-ferrous melting, we must look at its fundamental operating principle. It is a clean, contained, and highly efficient method of generating heat precisely where it's needed.

The Principle of Induction Heating

An induction furnace does not use a flame or external heating element. Instead, it generates a powerful, high-frequency alternating magnetic field.

This magnetic field penetrates a graphite crucible placed within the furnace's coil. The field induces strong electrical eddy currents within the graphite, causing it to heat up rapidly due to its natural electrical resistance.

The Critical Role of the Graphite Crucible

The graphite crucible is the key component. It acts as a "susceptor," absorbing the electromagnetic energy and converting it into pure heat.

This heat is then transferred to the non-ferrous metal charge inside the crucible through conduction and radiation. The metal melts cleanly without ever coming into contact with a flame or combustion byproducts.

Unmatched Purity and Control

This method provides two decisive advantages for non-ferrous metals. First, the contained atmosphere prevents the metal from reacting with oxygen, drastically reducing the formation of dross (impurities and oxides) and maximizing your yield.

Second, the power input can be controlled with surgical precision, allowing you to achieve and hold exact temperatures. This is vital for alloys with specific casting temperature requirements.

Understanding the Trade-offs

While induction furnaces are the professional standard for quality, it's important to weigh them against other methods to understand the complete picture. The choice always involves balancing performance against cost and complexity.

Induction Furnaces: Key Advantages

The primary benefits are clear:

- Speed: A powerful induction furnace can melt a full load in minutes.

- Efficiency: More energy is converted directly into useful heat compared to fuel-fired furnaces where much is lost to the environment.

- Cleanliness: The process produces no combustion gases, leading to a cleaner final product and work environment.

Considerations and Limitations

The main drawback is the initial investment. Induction furnaces and their associated power supplies represent a higher capital cost than simple gas or propane furnaces.

They also require a robust electrical infrastructure to operate, which may not be available in every workshop.

Gas-Fired Furnaces: The Alternative

The more traditional approach involves using burners fueled by natural gas or propane. These furnaces heat the metal through direct flame impingement or by heating a chamber.

While less expensive to build or buy, this method introduces significant oxidation, as the open flame's atmosphere is rich in oxygen. This leads to greater metal loss and can introduce impurities into the melt, which is particularly problematic for sensitive metals like aluminum.

Making the Right Choice for Your Goal

Selecting the right furnace depends entirely on your specific objectives for quality, volume, and budget.

- If your primary focus is high-purity melts and production efficiency: An induction furnace is the definitive choice for consistent, high-quality results with minimal metal loss.

- If your primary focus is low initial cost for hobbyist or small-scale work: A gas-fired furnace can be a viable starting point, but you must be prepared to manage the significant drawbacks of oxidation and impurity control.

- If your primary focus is melting extremely high-temperature metals (above 1800°C): A specialized, high-power induction furnace is the only practical and efficient solution.

Ultimately, investing in the right melting technology is a direct investment in the quality of your final product.

Summary Table:

| Feature | Induction Furnace | Gas-Fired Furnace |

|---|---|---|

| Heating Method | Non-contact magnetic induction | Direct flame or chamber heating |

| Purity & Oxidation | Minimal oxidation, high purity | High oxidation, lower purity |

| Speed & Efficiency | Fast melting, high energy efficiency | Slower melting, lower efficiency |

| Ideal Use Case | High-quality production, sensitive alloys | Hobbyist or small-scale work |

| Initial Cost | Higher investment | Lower initial cost |

Upgrade your metal melting process with KINTEK's precision induction furnaces.

As specialists in laboratory equipment, KINTEK provides robust induction furnaces designed to deliver the superior purity, efficiency, and control your non-ferrous metal work demands. Minimize oxidation, maximize yield, and achieve consistent, high-quality results.

Ready to enhance your melting capabilities? Contact our experts today to find the perfect furnace solution for your laboratory needs.

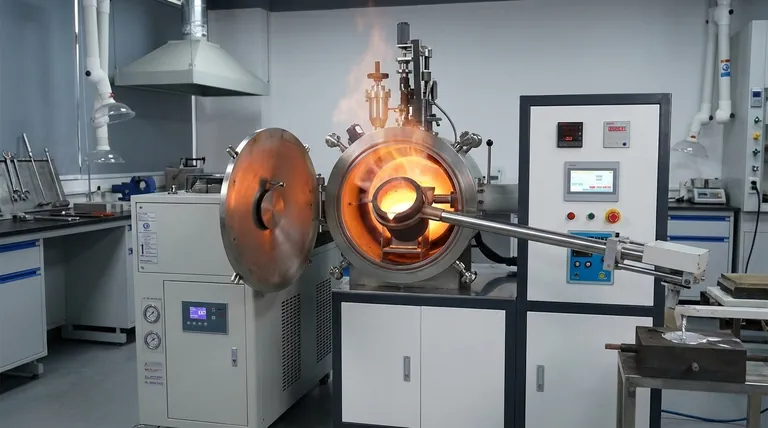

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- What is induction annealing? Unlock Fast, Precise Heat Treatment for Metals

- What role does a Vacuum Induction Melting Furnace play in 1.25Cr-0.5Mo steel ingots? Ensure Compositional Precision

- Why use vacuum melting for CoCrPtB alloys? Essential Pressure Control for High-Performance Magnetic Materials

- How do you cool an induction coil? Master the Key to System Reliability and Performance

- What are the factors on which heat generation depends in induction heating? Master Precise Thermal Control

- What is the primary function of vacuum melting equipment in Ti-Zr-Ni alloy preparation? Ensure Purity and Phase Stability

- What is the process of induction brazing? Achieve Fast, Precise, and Repeatable Metal Joining

- How does frequency affect induction heating? Master Heating Depth for Your Application