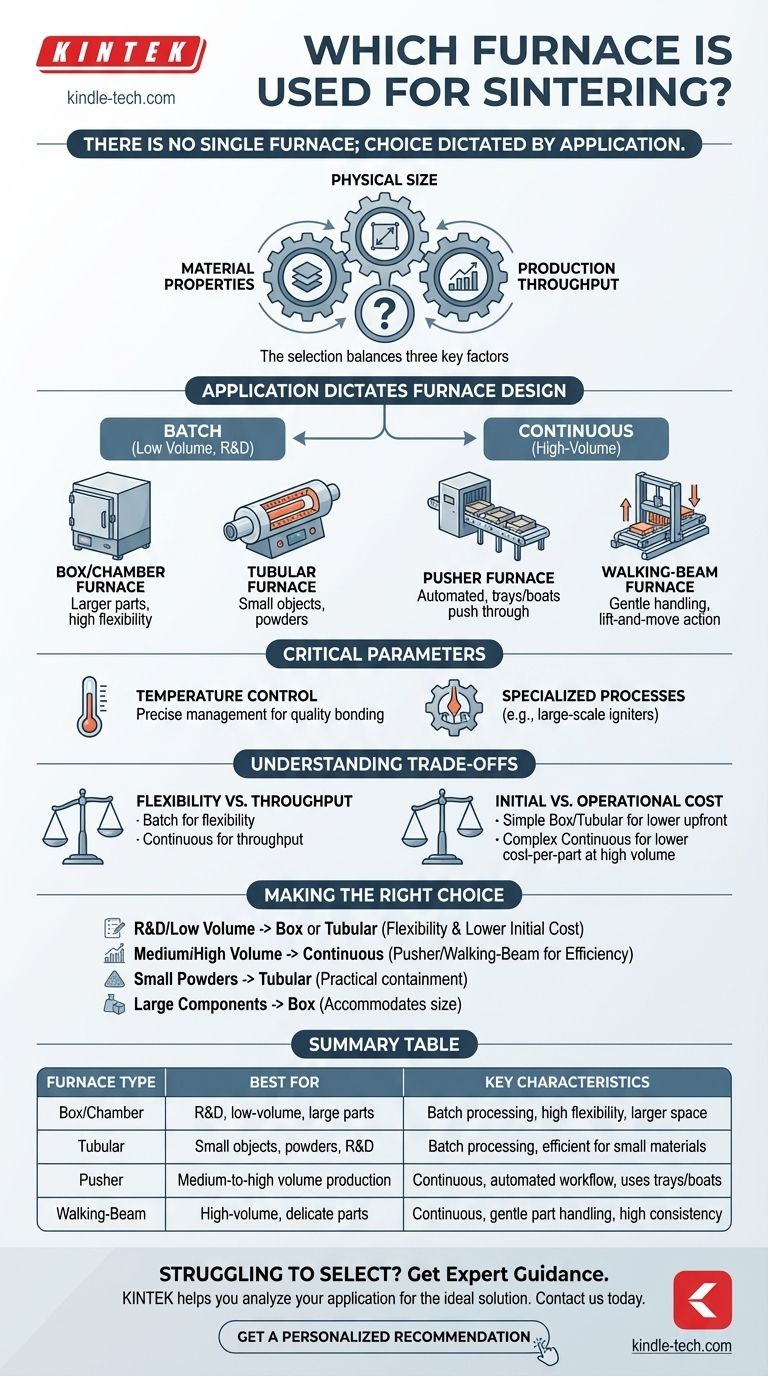

There is no single furnace for sintering; the correct choice is dictated entirely by the application's material, production volume, and component size. The most common types range from box and tubular furnaces for research and low-volume work to continuous systems like pusher and walking-beam furnaces for high-volume industrial manufacturing.

The selection of a sintering furnace is a critical decision that balances three key factors: the material properties you need to achieve, the physical size of your parts, and the required production throughput. Understanding your specific application is the only way to choose the right equipment.

How Application Dictates Furnace Design

The term "sintering furnace" describes a category of equipment, not a specific model. The most significant distinctions are based on how material is processed, which is a direct function of production scale and component characteristics.

Production Volume: Batch vs. Continuous

The most fundamental choice is between processing parts in individual groups (batch) or in a constant flow (continuous).

Batch furnaces are ideal for low-volume production, research and development, or products with highly variable processing requirements. They operate much like a conventional oven, processing one load at a time.

Continuous furnaces are designed for medium- to high-volume manufacturing. They create an efficient, automated workflow where parts constantly enter, move through the heating zones, and exit, ensuring high consistency for a standardized product.

Component Size and Form: Tubular vs. Box

For batch processing, the physical shape of the material often determines the best furnace type.

Tubular furnaces are exceptionally well-suited for sintering small objects or materials like powders and particle ores. The materials can be inserted directly into the furnace's tube for efficient and uniform heating.

Box furnaces, also known as chamber furnaces, offer a larger interior space. This makes them the standard choice for sintering larger individual objects or for surface treatment applications on bigger components.

Material Handling in Continuous Systems: Pusher vs. Walking-Beam

In high-volume continuous systems, the method for moving parts through the furnace is a key design feature.

Pusher furnaces move work through the heat zones on a series of trays or "boats." Each new boat pushes the entire train of boats ahead of it, creating a continuous flow.

Walking-beam furnaces use a more complex mechanism. Beams lift the product, move it forward a set distance, lower it back onto a stationary hearth, and then return to their starting position. This motion can be gentler on delicate parts.

Key Parameters That Ensure Quality Sintering

Regardless of the furnace type, the success of the sintering process hinges on precise control over the environment within the furnace.

The Critical Role of Temperature Control

Precise temperature management is the most important factor in achieving high-quality sintered products. The process requires heating the material to a specific temperature below its melting point and holding it there consistently.

A high-precision controller is essential for adjusting and stabilizing the temperature throughout the sintering chamber. This consistency ensures that the material bonds correctly and uniformly, yielding a reliable end product.

Specialized Sintering Processes

Sintering is a versatile technology applied in diverse fields, sometimes requiring unique equipment.

For example, large-scale iron ore sintering often uses a complex machine with a dedicated igniter to start the burning process on a moving bed. In other cases, like forming the lining of an induction furnace, the process involves heating the lining material itself to create a solid, protective ceramic structure. These are highly specialized applications of sintering principles.

Understanding the Trade-offs

Choosing a furnace involves balancing initial cost, operational flexibility, and long-term efficiency. There is no universally superior option.

Flexibility vs. Throughput

Batch furnaces offer maximum flexibility. You can easily change the temperature profile, processing time, and atmosphere for each new load. This advantage comes at the cost of lower throughput and potentially higher labor costs per unit.

Continuous furnaces are built for efficiency and high throughput. They excel at producing large quantities of a single product with minimal variation, but they are inflexible and not easily adapted to different products or processes.

Initial Cost vs. Operational Cost

Simple box or tubular furnaces have a significantly lower upfront investment and are generally easier to operate and maintain.

Complex continuous furnaces, especially walking-beam systems, represent a major capital expenditure. While their cost per part is lower at high volumes due to automation and efficiency, they require a substantial initial investment and more sophisticated maintenance.

Making the Right Choice for Your Goal

Your selection must be guided by a clear understanding of your operational priorities and the nature of the product you are creating.

- If your primary focus is R&D or low-volume custom parts: A box or tubular furnace provides the necessary process flexibility and lower initial cost.

- If your primary focus is medium- to high-volume standardized production: A continuous furnace, such as a pusher or walking-beam model, is the most efficient choice for consistency and low cost-per-part.

- If your primary focus is processing small powders or granular materials: A tubular furnace is often the most practical and effective solution for containing and heating these materials.

- If your primary focus is sintering large, bulky components: A box furnace or a custom-designed continuous system will be necessary to accommodate the physical size.

Ultimately, defining your operational needs with precision is the first and most critical step toward selecting the ideal sintering furnace.

Summary Table:

| Furnace Type | Best For | Key Characteristics |

|---|---|---|

| Box/Chamber | R&D, low-volume, large parts | Batch processing, high flexibility, larger interior space |

| Tubular | Small objects, powders, R&D | Batch processing, efficient for small or granular materials |

| Pusher | Medium-to-high volume production | Continuous processing, automated workflow, uses trays/boats |

| Walking-Beam | High-volume, delicate parts | Continuous processing, gentle part handling, high consistency |

Struggling to select the ideal sintering furnace for your specific material and production goals? The right equipment is critical for achieving consistent quality and optimal throughput. KINTEK specializes in lab equipment and consumables, serving laboratory needs with expert guidance. Our team can help you analyze your application—whether it's R&D with a batch furnace or high-volume production with a continuous system—to ensure you get a solution that balances performance, flexibility, and cost. Contact us today via the form below to discuss your project and discover how KINTEK can support your sintering success.

Get a Personalized Recommendation

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- How does a vacuum environment system contribute to the hot pressing sintering of B4C-CeB6? Unlock Peak Ceramic Density

- What technical functions does a vacuum hot pressing sintering furnace provide? Optimize CoCrFeNi Alloy Coatings

- What role does a vacuum hot pressing sintering furnace play for nanocopper? Achieve Maximum Densification Today

- What are the advantages of using a vacuum hot pressing furnace? Achieve 98.9% Density in Al2O3-TiC Laminated Ceramics