To be precise, overheating protection in a muffle furnace is not accomplished by a single type of material, but by a safety system. This system relies on robust, heat-containing refractory materials like high-strength alumina or silicon carbide, but the actual protection mechanism is an electronic circuit that provides automatic shut-off when temperatures exceed a safe limit.

Your furnace's safety doesn't come from one magic material. It comes from a partnership between passive, heat-resistant insulation and an active, intelligent electronic safety system that constantly monitors and protects against failure.

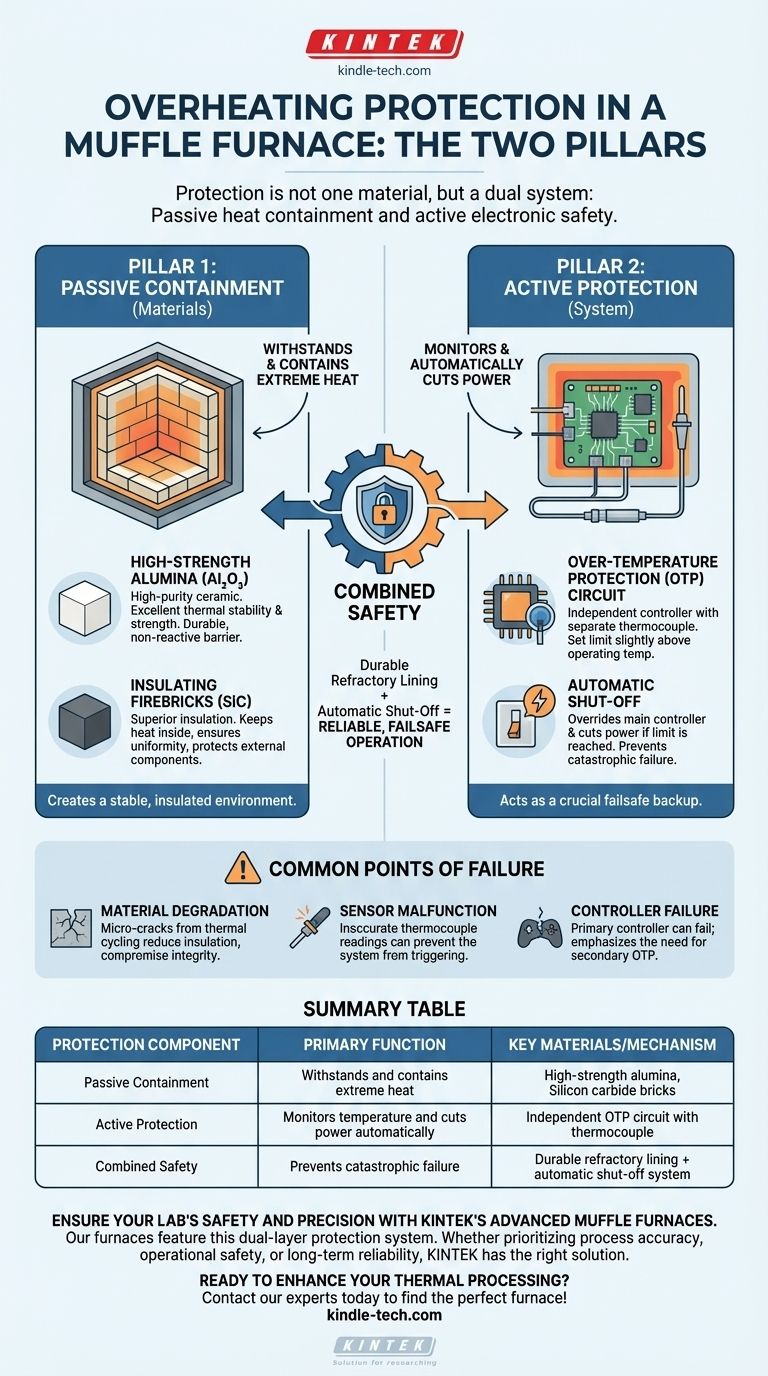

The Two Pillars of Thermal Protection

A muffle furnace manages extreme heat using two distinct but complementary strategies: passive containment and active protection. Understanding both is key to understanding its safety.

Pillar 1: Passive Containment (The Materials)

The furnace chamber, or "muffle," is lined with materials designed to withstand and contain immense heat.

High-Strength Alumina (Al₂O₃) This is a high-purity ceramic known for its excellent thermal stability and strength at high temperatures. It forms a durable, non-reactive barrier.

Insulating Firebricks (Silicon Carbide - SiC) These specialized bricks are engineered for superior insulation. Their primary job is to keep heat inside the chamber, ensuring temperature uniformity and protecting the furnace's external components.

These refractory materials don't prevent overheating on their own. They create a stable, insulated environment where temperature can be controlled effectively.

Pillar 2: Active Protection (The System)

This is the furnace's true safety net. It's an electronic system designed to intervene if the primary temperature controller fails.

Over-Temperature Protection (OTP) Circuit This is typically an independent controller with its own temperature sensor (thermocouple). You set its limit slightly above your desired operating temperature.

Automatic Shut-Off If the chamber temperature ever reaches the OTP limit, this circuit will override the main controller and cut power to the heating elements, preventing a catastrophic failure.

How the Systems Work Together

Think of the refractory lining as the strong walls of a fortress and the OTP circuit as the vigilant guard at the gate.

Containment and Stability

The alumina or silicon carbide lining ensures the intense heat generated is kept within the chamber, allowing for an accurate and stable process environment.

Failsafe Monitoring

The independent OTP circuit acts as a crucial backup. If the primary controller malfunctions and continues to send power to the heating elements, the OTP provides a hard safety stop, preventing the furnace from destroying itself.

Common Points of Failure

Even with robust systems, no component is infallible. Understanding potential weaknesses is crucial for safe operation.

Material Degradation

Over many cycles of heating and cooling, refractory materials can develop micro-cracks. This reduces their insulating effectiveness and can eventually compromise the chamber's integrity.

Sensor Malfunction

The entire active protection system depends on an accurate temperature reading from its thermocouple. If this sensor fails or becomes inaccurate, the system may not trigger when it's supposed to.

Controller Failure

The primary controller is the most complex component and can fail. This is precisely why a secondary, independent over-temperature protection circuit is not a luxury, but a critical safety feature.

Making the Right Choice for Your Goal

When evaluating a muffle furnace, consider how these systems align with your primary needs.

- If your primary focus is process accuracy: Prioritize furnaces with high-quality, dense refractory linings like high-purity alumina for maximum temperature uniformity and stability.

- If your primary focus is operational safety: Confirm the furnace has an independent over-temperature protection circuit with an automatic power cut-off, separate from the main temperature controller.

- If your primary focus is long-term reliability: Choose a unit with durable components and commit to a regular maintenance schedule to inspect the chamber lining and calibrate the thermocouples.

Ultimately, a safe furnace is one where high-endurance materials and intelligent safety systems work in concert to protect both your work and your lab.

Summary Table:

| Protection Component | Primary Function | Key Materials/Mechanism |

|---|---|---|

| Passive Containment | Withstands and contains extreme heat | High-strength alumina (Al₂O₃), Silicon carbide (SiC) bricks |

| Active Protection | Monitors temperature and cuts power automatically | Independent over-temperature protection (OTP) circuit with thermocouple |

| Combined Safety | Prevents catastrophic failure through material stability and electronic failsafe | Durable refractory lining + automatic shut-off system |

Ensure your lab's safety and precision with KINTEK's advanced muffle furnaces.

Our furnaces feature the dual-layer protection system described above—combining durable high-purity alumina chambers with independent over-temperature protection circuits for reliable, failsafe operation. Whether you prioritize process accuracy, operational safety, or long-term reliability, KINTEK has the right laboratory equipment for your needs.

Ready to enhance your thermal processing? Contact our experts today to find the perfect muffle furnace for your application!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Why is a high-precision Muffle Furnace essential for AFA steel? Optimize Your Solution Treatment Results

- What role does a high-temperature muffle furnace play in FM steel heat treatment? Expert Microstructure Engineering

- Why is a high-temperature box furnace used for 600 °C TiO2 nanobelt annealing? Optimize Phase & Performance

- What is the function of a chamber furnace? Master Precise Thermal Processing for Your Materials

- Why is a high-temperature muffle furnace necessary for zeolite pretreatment? Achieve Superior Thermal Activation

- What are the advantages of sintered materials? Achieve High-Performance, Custom Material Properties

- What advantages does a hybrid microwave high-temperature furnace offer? Superior Li1.5La1.5MO6 Synthesis Results

- How are ceramics sintered? Mastering the High-Temperature Process for Stronger Materials