For depositing a Zinc Oxide (ZnO) thin film, both Radio-Frequency (RF) and Direct Current (DC) magnetron sputtering systems are widely and effectively used. The specific choice between them is not about which one is "better" overall, but which is appropriate for the type of source material, or "target," you intend to use.

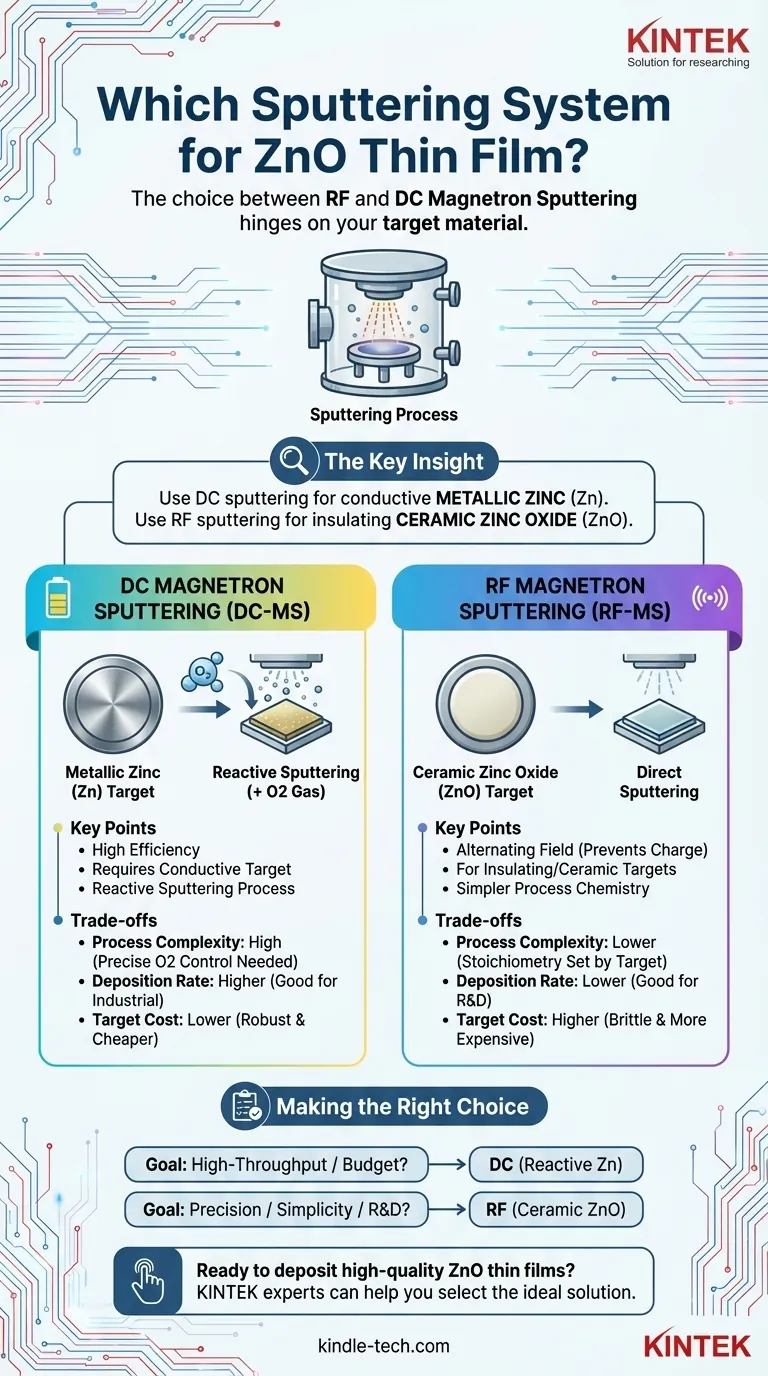

The central decision between sputtering systems for ZnO hinges on your starting material. Use DC sputtering for a conductive, metallic zinc (Zn) target in a reactive oxygen environment, and use RF sputtering for an insulating, ceramic zinc oxide (ZnO) target.

Understanding Sputtering for ZnO Deposition

What is Sputtering?

Sputtering is a Physical Vapor Deposition (PVD) technique. It works by bombarding a source material, called a target, with energized ions in a vacuum. This impact physically ejects atoms from the target, which then travel and deposit onto a substrate, forming a thin film.

The Advantage of Magnetron Sputtering

Magnetron sputtering enhances this process by using strong magnetic fields to trap electrons near the target surface. This confinement intensifies the ionization of the sputtering gas (like Argon), leading to a denser plasma, higher sputtering rates, and less substrate heating.

This method is highly valued for its precision. It allows for excellent control over the film's properties and can produce films with less than 2% thickness variation across a substrate.

The Critical Choice: RF vs. DC Systems

The fundamental difference between RF and DC sputtering lies in the type of electrical power used to generate the plasma. This dictates which type of target material can be used effectively.

DC Magnetron Sputtering (DC-MS)

DC sputtering uses a direct current power supply. This method is highly efficient but requires the target material to be electrically conductive.

For ZnO deposition, this means you must use a metallic zinc (Zn) target. The zinc atoms are sputtered from the target, and oxygen gas is simultaneously introduced into the chamber. This is known as reactive sputtering, where the zinc and oxygen react on the substrate surface to form the desired ZnO film.

RF Magnetron Sputtering (RF-MS)

RF sputtering uses an alternating, radio-frequency power supply. The rapid switching of the electric field prevents the build-up of electrical charge on the target surface.

This is the key advantage of RF sputtering: it can be used with electrically insulating (or ceramic) targets. Therefore, you can sputter directly from a pre-made, solid zinc oxide (ZnO) target. The sputtered material is already ZnO, simplifying the process chemistry.

Understanding the Trade-offs

Choosing between these two valid methods involves practical trade-offs in process control, cost, and deposition rate.

Process Complexity

Reactive DC sputtering requires very precise control over the oxygen gas flow. Too little oxygen results in a metal-rich, non-stoichiometric film. Too much oxygen can "poison" the metallic target by forming an insulating oxide layer on its surface, which drastically reduces the sputtering rate.

RF sputtering from a ceramic ZnO target is often more straightforward, as the material's stoichiometry is already set by the target itself.

Deposition Rate

Generally, reactive DC sputtering from a metallic target can achieve higher deposition rates than RF sputtering from a ceramic target. This makes it attractive for industrial applications where throughput is a major concern.

Target Cost and Durability

Metallic zinc targets are typically less expensive and more robust than ceramic ZnO targets. Ceramic targets can be more brittle and susceptible to cracking from thermal shock.

Making the Right Choice for Your Goal

Your equipment, budget, and desired film properties will determine the best path forward.

- If your primary focus is high-throughput or industrial production: Reactive DC sputtering from a metallic zinc target is often preferred for its higher deposition rates.

- If your primary focus is precise stoichiometry and process simplicity: RF sputtering from a ceramic ZnO target is an excellent and highly repeatable choice, especially for R&D.

- If you are constrained by budget or existing equipment: Using a metallic Zn target with a DC system is often the most cost-effective approach, provided you have precise gas flow control.

Ultimately, both RF and DC magnetron sputtering are proven, industry-standard methods for producing high-quality ZnO thin films.

Summary Table:

| Sputtering Method | Target Material | Key Characteristic |

|---|---|---|

| DC Magnetron | Metallic Zinc (Zn) | Reactive sputtering with oxygen; higher deposition rates |

| RF Magnetron | Ceramic Zinc Oxide (ZnO) | Direct sputtering of ZnO; simpler process control |

Ready to deposit high-quality ZnO thin films? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Whether you require a robust DC system for high-throughput production or a precise RF system for R&D, our experts can help you select the ideal sputtering solution. Contact us today to discuss your project and achieve optimal film results!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

People Also Ask

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What is the difference between PECVD and sputter? Choose the Right Thin-Film Deposition Method

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition