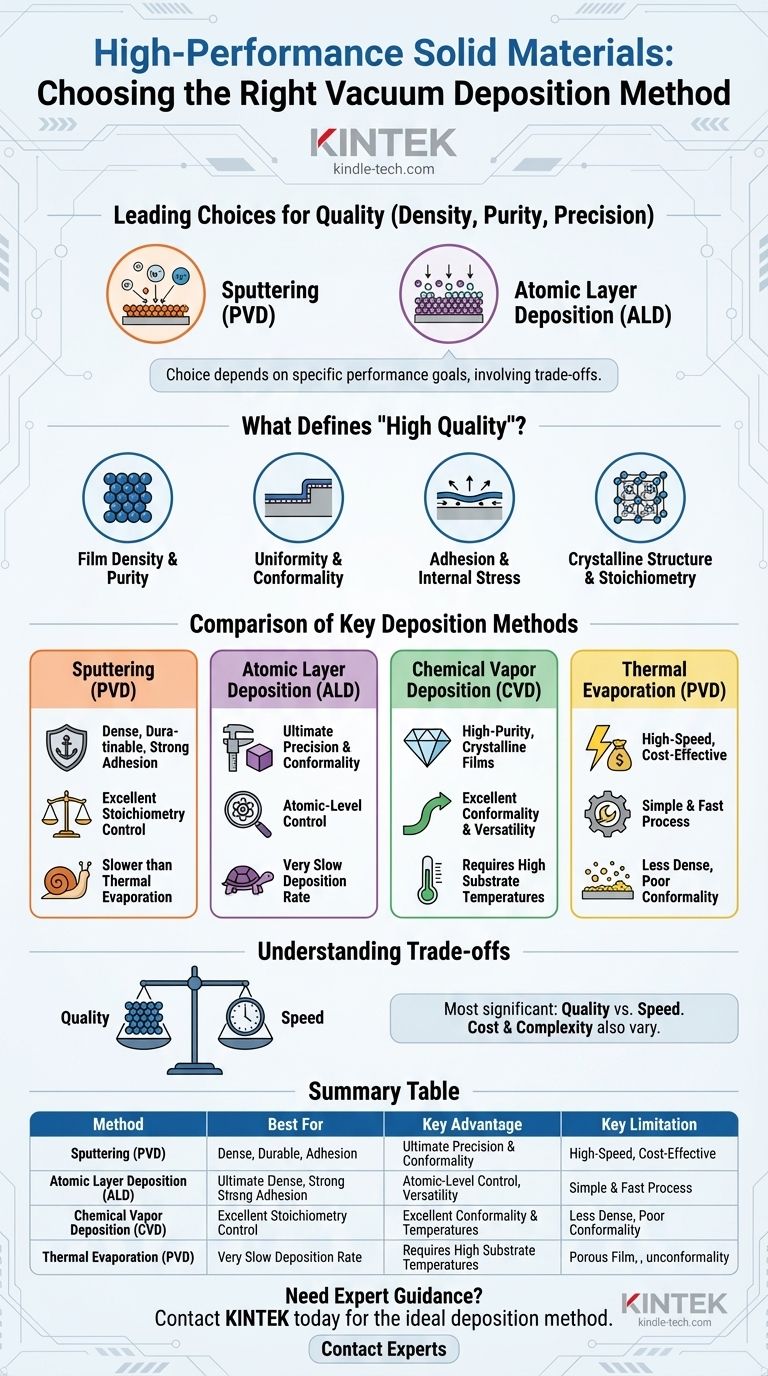

When producing high-performance solid materials, the choice of vacuum deposition method is critical, as no single technique excels in all areas. For the highest quality in terms of density, purity, and precision, Sputtering (a form of Physical Vapor Deposition) and Atomic Layer Deposition (ALD) are the industry's leading choices. Sputtering is favored for its ability to create dense, durable films with excellent adhesion, while ALD offers unparalleled control for perfectly uniform and conformal coatings at the atomic level.

The "best" vacuum deposition method is not a single technique but a choice dictated by your specific performance goals. While methods like Sputtering and ALD offer superior control over film properties, the ideal choice always involves a trade-off between film quality, deposition rate, and cost.

What Defines "High Quality" in a Thin Film?

Before comparing methods, we must define the key metrics of a "high-performance" or "high-quality" thin film. The importance of each metric depends entirely on the final application, whether it's an optical coating, a semiconductor device, or a wear-resistant surface.

Film Density and Purity

High-quality films are dense, with minimal voids or gaps. Voids can alter optical properties, reduce durability, and allow contaminants to penetrate the film. Purity is equally critical, as even trace amounts of unwanted elements can degrade electrical, optical, or mechanical performance.

Film Uniformity and Conformality

Uniformity refers to maintaining a consistent film thickness across the entire surface of a flat substrate. Conformality (or step coverage) is the ability to coat complex, three-dimensional surfaces evenly, without thinning or breaks over sharp edges or in deep trenches.

Adhesion and Internal Stress

A film is useless if it doesn't stick to the substrate. Strong adhesion is a hallmark of a quality deposition process. Furthermore, films can have internal stress (compressive or tensile) that can cause them to crack, peel, or even bend the substrate, making stress management crucial.

Crystalline Structure and Stoichiometry

For many advanced materials, achieving the correct crystalline structure (e.g., amorphous vs. polycrystalline) and stoichiometry (the precise ratio of elements in a compound) is essential for function.

A Comparison of Key Deposition Methods

Each vacuum deposition technique operates on different principles, giving it a unique profile of strengths and weaknesses when measured against our quality metrics.

Sputtering (PVD): The Workhorse for Dense Films

In sputtering, high-energy ions bombard a target material, ejecting atoms that then travel and deposit onto the substrate.

The high kinetic energy of the sputtered atoms results in very dense films with strong adhesion. This process offers excellent control over the stoichiometry of complex materials, making it a go-to for high-performance optical coatings, wear-resistant layers, and metallization in electronics.

Atomic Layer Deposition (ALD): The Ultimate in Precision

ALD is a unique process where the film is built one atomic layer at a time through a series of self-limiting chemical reactions.

This method provides the absolute best conformality and uniformity possible, perfectly coating even the most complex 3D nanostructures. It also offers pinpoint control over thickness. However, this precision comes at the cost of being an extremely slow deposition method.

Chemical Vapor Deposition (CVD): Versatility for Complex Materials

CVD involves introducing precursor gases into a chamber, where they react and decompose on a heated substrate to form the desired film.

CVD is renowned for producing highly pure, crystalline films with excellent conformality. It is a powerful and versatile technique, but often requires very high substrate temperatures, which can damage sensitive components.

Thermal Evaporation (PVD): The Choice for Speed and Simplicity

This is one of the simplest methods, where a source material is heated in a vacuum until it evaporates, with the vapor then condensing on a cooler substrate.

While very fast and cost-effective, thermal evaporation typically produces films that are less dense and have weaker adhesion than sputtered films. Because it is a "line-of-sight" technique, its ability to conformally coat complex shapes is poor.

Understanding the Trade-offs

Selecting a deposition method is an engineering decision that requires balancing competing priorities. There is no universally superior choice.

Quality vs. Speed

The most significant trade-off is often between film quality and deposition speed. ALD produces nearly perfect films but is exceptionally slow. On the other end, Thermal Evaporation is very fast but generally produces lower-quality films. Sputtering and CVD offer a balance between the two.

Cost and Complexity

The equipment and precursors required for different methods vary widely in cost. Thermal evaporation systems are relatively simple and inexpensive. Sputtering systems are more complex, while ALD and CVD systems can be highly sophisticated and expensive to purchase and operate.

Material and Substrate Compatibility

The choice is often limited by the materials themselves. Some alloys or compounds can only be effectively deposited via sputtering. Certain crystalline structures might only be achievable with high-temperature CVD. Similarly, the heat sensitivity of your substrate may immediately rule out methods like traditional CVD.

Making the Right Choice for Your Goal

Your application's most critical performance metric should guide your decision.

- If your primary focus is ultimate precision and perfect uniformity over complex 3D structures: Atomic Layer Deposition (ALD) is the unparalleled choice, despite its slow speed.

- If your primary focus is producing dense, durable, and pure films with strong adhesion: Sputtering is the most robust and versatile PVD method for a wide range of high-performance applications.

- If your primary focus is creating highly conformal, pure crystalline films that may be difficult to produce otherwise: Chemical Vapor Deposition (CVD) is a powerful option, provided your substrate can handle the high temperatures.

- If your primary focus is high-speed deposition for less demanding applications: Thermal Evaporation offers a cost-effective and rapid solution, but with compromises in film density and coverage.

By aligning the distinct advantages of each deposition method with your specific definition of "performance," you can select the optimal process for creating superior solid materials.

Summary Table:

| Method | Best For | Key Advantage | Key Limitation |

|---|---|---|---|

| Sputtering (PVD) | Dense, durable films; Strong adhesion | Excellent control over stoichiometry | Slower than thermal evaporation |

| Atomic Layer Deposition (ALD) | Ultimate precision & conformality | Atomic-level control & uniformity | Very slow deposition rate |

| Chemical Vapor Deposition (CVD) | High-purity, crystalline films | Excellent conformality & versatility | Requires high substrate temperatures |

| Thermal Evaporation (PVD) | High-speed, cost-effective deposition | Simple and fast process | Less dense films; Poor conformality |

Need expert guidance to select the ideal deposition method for your high-performance materials? The choice between sputtering, ALD, and CVD is critical for achieving the desired film density, purity, and precision. At KINTEK, we specialize in providing advanced lab equipment and consumables tailored to your specific research and production goals. Our team can help you navigate the trade-offs to optimize your process efficiency and material performance. Contact our experts today to discuss your application and discover the right solution for your laboratory needs.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is the temperature of a thermal CVD? Key Ranges for High-Quality Film Deposition

- What are the vapor phase deposition techniques? Choose the Right Method for Superior Thin Films

- How is magnetron sputtering different from other methods? Unlock High-Speed, Quality Thin Films

- What are the advantages of using a hot-wall LP-MOCVD system? Superior Conformal Coating for Complex 3D Geometries

- What role does a CVD reactor play in catalytic pyrolysis of LDPE and PP? Optimize Your Plastic Recycling Research

- What are the different types of chemical vapor deposition process? Select the Right CVD Method for Your Lab

- Why is a substrate stage cooling system critical in high-power density plasma CVD? Master Extreme Thermal Management

- What is the difference between lab grown and CVD diamonds? Understanding the Two Main Creation Methods