At their core, ceramics are used in medical implants for their unique combination of exceptional biocompatibility, high wear resistance, and chemical stability. Unlike metals, they are bioinert, meaning the human body does not typically recognize them as foreign objects, which dramatically reduces the risk of immune reactions or inflammation. This allows them to function safely within the body for decades.

The central challenge in implant design is not just finding a strong material, but finding one the body will accept long-term. Ceramics excel because they are chemically silent, resisting corrosion and wear while providing the structural support needed for applications like joint replacements and dental implants.

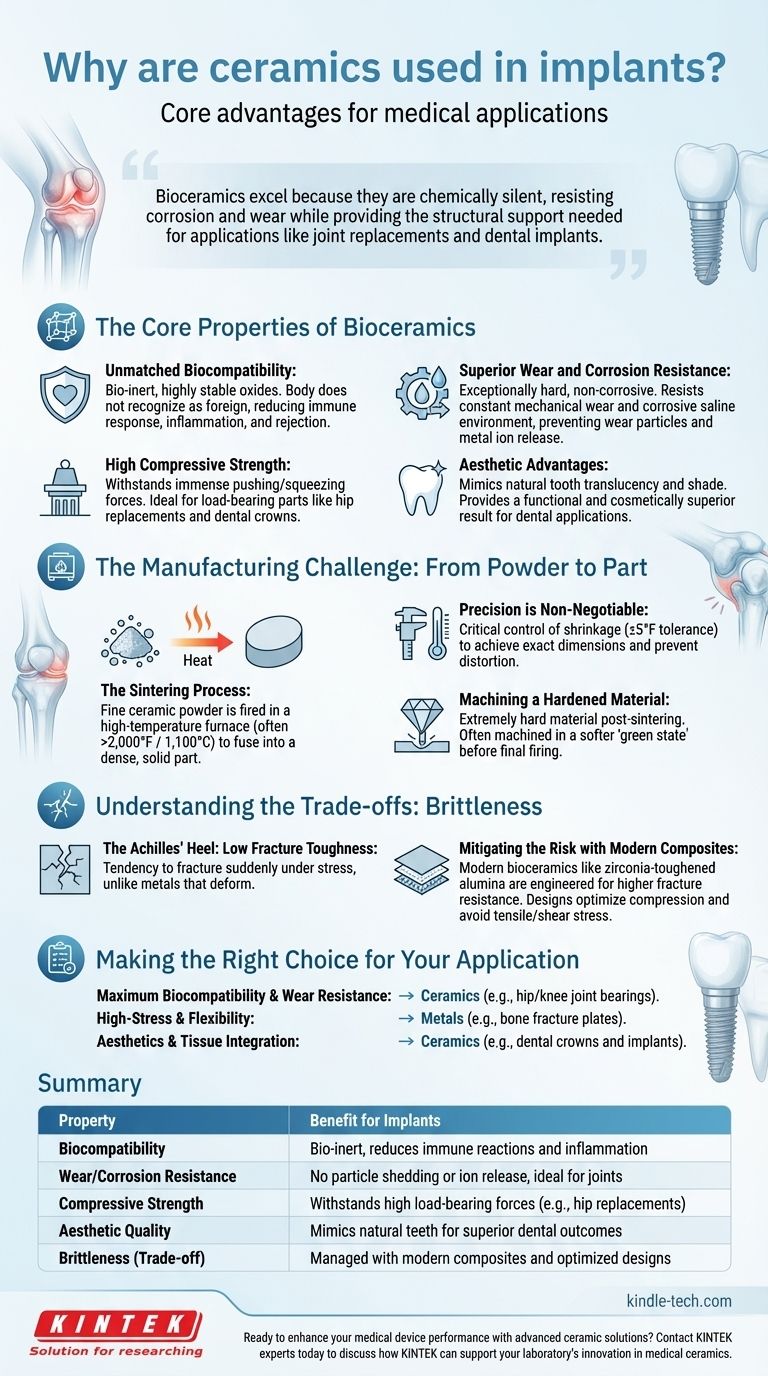

The Core Properties of Bioceramics

To understand why ceramics are a premier choice, we must look at their fundamental material properties. These characteristics directly address the harsh and demanding environment inside the human body.

Unmatched Biocompatibility

The most critical property of any implant material is biocompatibility. Ceramic materials are typically oxides, which are highly stable and non-reactive.

The body's immune system does not trigger a significant response to them. This bio-inertness prevents the chronic inflammation, tissue rejection, and allergic reactions that can occur with certain metal alloys.

Superior Wear and Corrosion Resistance

Inside the body, implants are subject to constant mechanical wear and a corrosive saline environment. Ceramics are exceptionally hard and do not corrode.

This means a ceramic joint bearing will not shed wear particles or release metal ions into the bloodstream over time, which are significant long-term concerns with some metal-on-metal implants.

High Compressive Strength

Ceramics exhibit extremely high compressive strength, meaning they can withstand immense pushing or squeezing forces without failing.

This makes them ideal for load-bearing applications, such as the ball-and-socket components in a hip replacement or the chewing surfaces of a dental crown, where compressive forces are dominant.

Aesthetic Advantages

For visible applications like dental implants, aesthetics are crucial. Materials like zirconia can be colored and finished to perfectly mimic the translucency and shade of natural teeth.

This provides a functional and cosmetically superior result that is nearly indistinguishable from a real tooth.

The Manufacturing Challenge: From Powder to Part

The unique properties of ceramics are achieved through a highly controlled and demanding manufacturing process. This complexity is a key part of their story.

The Sintering Process

Ceramic implants begin as a fine, purified powder. This powder is formed into a rough shape and then fired in a high-temperature furnace, a process known as sintering.

As noted in manufacturing processes for dental implants, this requires extreme heat, often over 2,000°F (1,100°C), to fuse the powder particles into a dense, solid, and incredibly strong final part.

Precision is Non-Negotiable

During sintering, the ceramic part shrinks. Controlling this shrinkage is critical to achieving the exact dimensions required for a successful implant.

The furnace temperature must be maintained with incredible uniformity, often within a tolerance of ±5°F (2.5°C), to prevent distortion or internal stresses that could lead to failure.

Machining a Hardened Material

Once fired, ceramics are one of the hardest materials known. This makes any final machining extremely difficult and expensive.

Often, the part is machined into its near-final shape in a pre-sintered "green state" when it is much softer, and then fired to its final hardness and dimensions.

Understanding the Trade-offs: Brittleness

No material is perfect. The primary trade-off for the exceptional hardness and biocompatibility of ceramics is their brittleness.

The Achilles' Heel: Low Fracture Toughness

Unlike metals, which can bend or deform under extreme stress, ceramics tend to fracture suddenly. This property is known as low fracture toughness.

An early generation of ceramic implants sometimes faced issues with catastrophic failure for this reason, which initially limited their use in very high-impact applications.

Mitigating the Risk with Modern Composites

Engineers have overcome this limitation through material science and design. Modern bioceramics, such as zirconia-toughened alumina, are composite materials designed to be significantly more fracture-resistant.

Furthermore, implant designs are optimized to keep ceramic components under compression, where they are strongest, and to avoid the types of tensile or shear stress that could lead to fracture.

Making the Right Choice for Your Application

The selection of an implant material always involves balancing competing requirements against the specific demands of the application.

- If your primary focus is maximum biocompatibility and wear resistance: For bearing surfaces like hip or knee joints, the inertness and durability of ceramic components are unparalleled.

- If your primary focus is high-stress applications requiring some flexibility: For devices like bone fracture plates, metals like titanium are still preferred for their superior fracture toughness and ability to bend before breaking.

- If your primary focus is aesthetics and tissue integration: For dental crowns and implants, ceramics like zirconia are the definitive choice for their tooth-like appearance and excellent interaction with gum tissue.

Ultimately, the use of ceramics in medicine is a testament to matching a material's unique strengths to a specific and challenging biological problem.

Summary Table:

| Property | Benefit for Implants |

|---|---|

| Biocompatibility | Bio-inert, reduces immune reactions and inflammation |

| Wear/Corrosion Resistance | No particle shedding or ion release, ideal for joints |

| Compressive Strength | Withstands high load-bearing forces (e.g., hip replacements) |

| Aesthetic Quality | Mimics natural teeth for superior dental outcomes |

| Brittleness (Trade-off) | Managed with modern composites and optimized designs |

Ready to enhance your medical device performance with advanced ceramic solutions? KINTEK specializes in high-performance lab equipment and consumables essential for developing and testing bioceramic materials. Our precise sintering furnaces and material testing tools help you achieve the exacting standards required for safe, long-lasting implants. Contact our experts today to discuss how KINTEK can support your laboratory's innovation in medical ceramics.

Visual Guide

Related Products

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

- Custom Boron Nitride (BN) Ceramic Parts

- Carbon Graphite Plate Manufactured by Isostatic Pressing Method

- Warm Isostatic Press for Solid State Battery Research

- Customizable PTFE Wafer Carriers for Semiconductor and Lab Applications

People Also Ask

- Which of the following is used in furnace to withstand high temperature? Key Materials for Extreme Heat

- Why are ceramics more resistant to corrosion? Unlock the Secret to Unmatched Chemical Stability

- Why are high-purity alumina rods used in LOCA experiments? Simulating Nuclear Fuel Gap and Steam Starvation

- What are the high temperature properties of alumina? Discover Its Stability, Strength, and Limits

- What is the maximum operating temperature of alumina? The Critical Role of Purity and Form