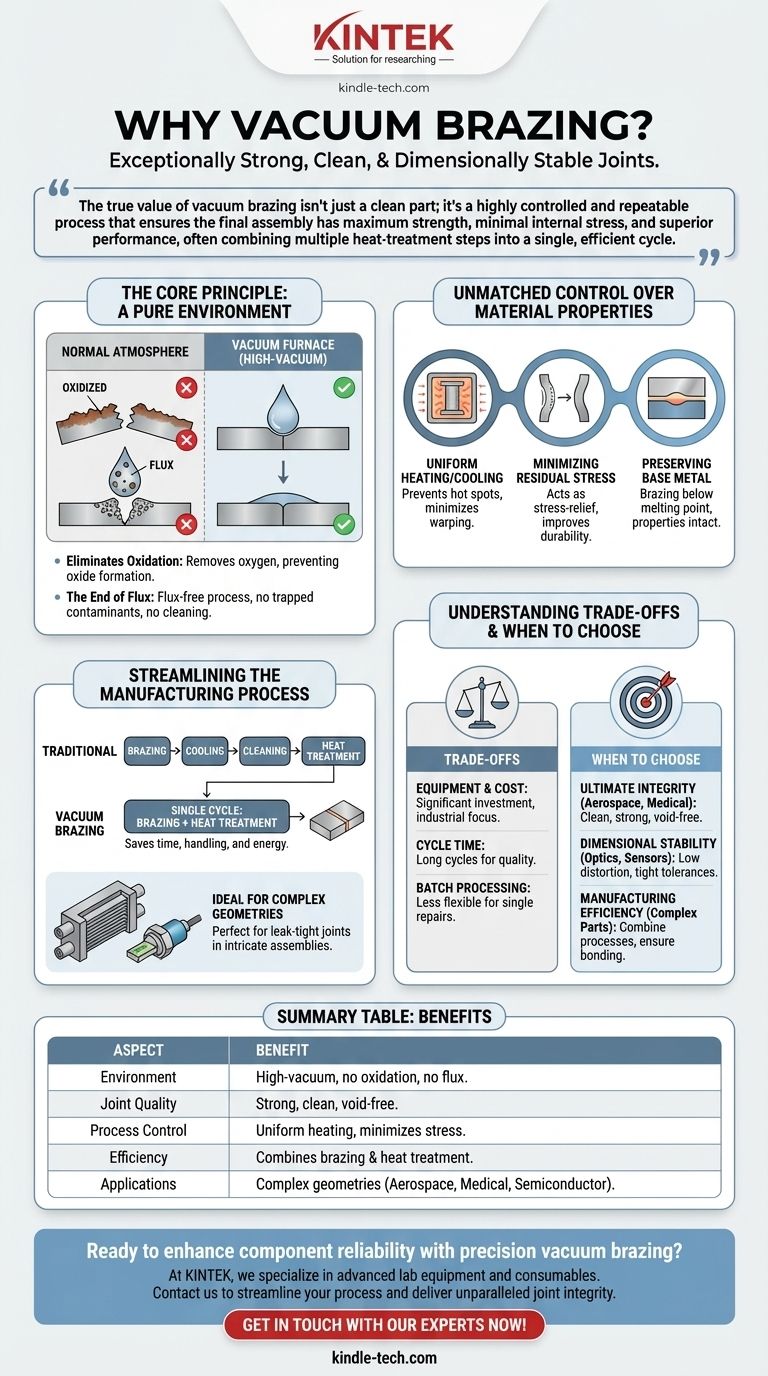

At its core, vacuum brazing is chosen for its ability to produce exceptionally strong, clean, and dimensionally stable joints. This is achieved by performing the joining process in a high-vacuum environment, which eliminates the atmospheric contaminants that plague other methods. The result is a flux-free joint with superior metallurgical properties, making it an essential process for mission-critical components in industries like aerospace, medical, and semiconductor manufacturing.

The true value of vacuum brazing isn't just a clean part; it's a highly controlled and repeatable process that ensures the final assembly has maximum strength, minimal internal stress, and superior performance, often combining multiple heat-treatment steps into a single, efficient cycle.

The Core Principle: A Pure Environment

The defining characteristic of vacuum brazing is the furnace environment itself. By removing the atmosphere, the process fundamentally changes how the metals interact, leading to superior results.

Eliminating Oxidation

In a normal atmosphere, heating metals causes them to form oxides on the surface. These oxide layers inhibit the flow of brazing filler metal and create weak points or voids in the final joint.

A vacuum furnace removes virtually all oxygen, preventing these oxides from ever forming. This allows the filler metal to wet and flow perfectly across the clean base metal surfaces.

The End of Flux

Traditional brazing methods rely on a chemical agent called flux to clean the metal surfaces and prevent oxidation. However, flux introduces its own problems.

Flux can become trapped within the joint, leading to corrosion and potential failure points over time. It also requires a thorough post-brazing cleaning process, adding time and cost. Vacuum brazing completely eliminates the need for flux, resulting in the highest possible joint integrity.

Unmatched Control Over Material Properties

Vacuum brazing provides a level of thermal control that is difficult to achieve with other methods. This precision is critical for maintaining the intended characteristics of the materials being joined.

Uniform Heating and Cooling

The furnace environment ensures that heat is applied uniformly across the entire assembly, regardless of its complexity or size. This prevents hot spots that can cause warping or distortion.

Slow, precisely controlled heating and cooling cycles are standard. This gentle thermal transition is key to maintaining tight dimensional tolerances.

Minimizing Residual Stress

Most metal components harbor internal stresses from prior manufacturing steps. The slow, controlled thermal cycles of vacuum brazing act as a stress-relief process.

This reduction in internal stress significantly improves the final part's thermal and mechanical properties, making it more durable and reliable in service.

Preserving the Base Metal

Brazing occurs at a temperature below the melting point of the base materials being joined. This ensures that the fundamental strength, grain structure, and other critical properties of the parent metals are minimally affected.

Streamlining the Manufacturing Process

Beyond joint quality, vacuum brazing offers significant efficiency gains, especially for complex assemblies or high-volume production.

Combining Brazing and Heat Treatment

Many high-performance parts require both joining and subsequent heat treatment (like hardening or age hardening). A vacuum furnace can perform these operations in a single, uninterrupted cycle.

An assembly can be heated to brazing temperature, joined, and then moved directly into a hardening or quenching cycle within the same furnace. This consolidation saves enormous amounts of time, handling, and energy.

Ideal for Complex Geometries

The uniform heating and the penetrating nature of the vacuum environment make this process perfect for joining intricate or difficult-to-reach assemblies.

It excels at creating leak-tight joints in complex products like micro-channel heat exchangers, sensors, and internal components where other methods simply cannot succeed.

Understanding the Trade-offs

While powerful, vacuum brazing is not the solution for every application. Objectivity requires acknowledging its specific operational characteristics.

Equipment and Cost

Vacuum furnaces represent a significant capital investment. The cost and complexity of the equipment mean this process is primarily suited for industrial and high-tech manufacturing environments.

Cycle Time

The emphasis on slow, controlled heating and cooling means that furnace cycles can be long, often lasting several hours. This is a trade-off for achieving low stress and high quality.

Batch Processing

Vacuum brazing is a batch process. While excellent for running many parts at once, it is less flexible than manual methods like torch brazing for quick, one-off repairs or prototypes.

When to Choose Vacuum Brazing

The decision to use vacuum brazing should be driven by the specific requirements of your final product.

- If your primary focus is ultimate joint integrity and reliability (aerospace, medical devices): Choose vacuum brazing for its clean, flux-free, and void-free joints that deliver maximum strength.

- If your primary focus is dimensional stability and low distortion (optics, sensors): The uniform heating and stress-relieving properties make it the superior choice for maintaining tight tolerances.

- If your primary focus is manufacturing efficiency for complex parts (heat exchangers): Use vacuum brazing to combine joining and heat treatment into a single cycle and ensure complete bonding of intricate assemblies.

Ultimately, you choose vacuum brazing when you need to engineer a joint with the same level of precision and reliability as the parent materials themselves.

Summary Table:

| Aspect | Benefit |

|---|---|

| Environment | High-vacuum eliminates oxidation, no flux required |

| Joint Quality | Exceptionally strong, clean, and void-free joints |

| Process Control | Uniform heating/cooling minimizes stress and distortion |

| Efficiency | Combines brazing and heat treatment in a single cycle |

| Applications | Ideal for complex geometries in aerospace, medical, and semiconductor industries |

Ready to enhance your component reliability with precision vacuum brazing? At KINTEK, we specialize in advanced lab equipment and consumables tailored for high-performance manufacturing. Our expertise ensures your mission-critical components achieve maximum strength, minimal stress, and superior performance. Contact us today to discuss how our solutions can streamline your process and deliver unparalleled joint integrity.

Get in touch with our experts now!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is a sintering kiln? The Essential Tool for Transforming 3D Printed Parts into Durable Components

- Which furnace removes most air to prevent decarburization? The Definitive Guide to Vacuum Furnaces

- How does the high vacuum environment benefit RuTi alloy preparation? Achieve Pure, High-Density Results

- What is the difference between annealing and tempering? Master the Heat Treatment Process for Your Metals

- What is the purpose of using a precision high-temperature aging furnace in hydrogen embrittlement research?

- Why is vacuum extraction combined with heating necessary in aminosiloxane synthesis? Ensure High Purity & Performance

- How do you braze a furnace? A Guide to High-Volume, Precision Metal Joining

- What role do high-temperature vacuum furnaces play in SLM stainless steel? Optimize Post-Processing Performance