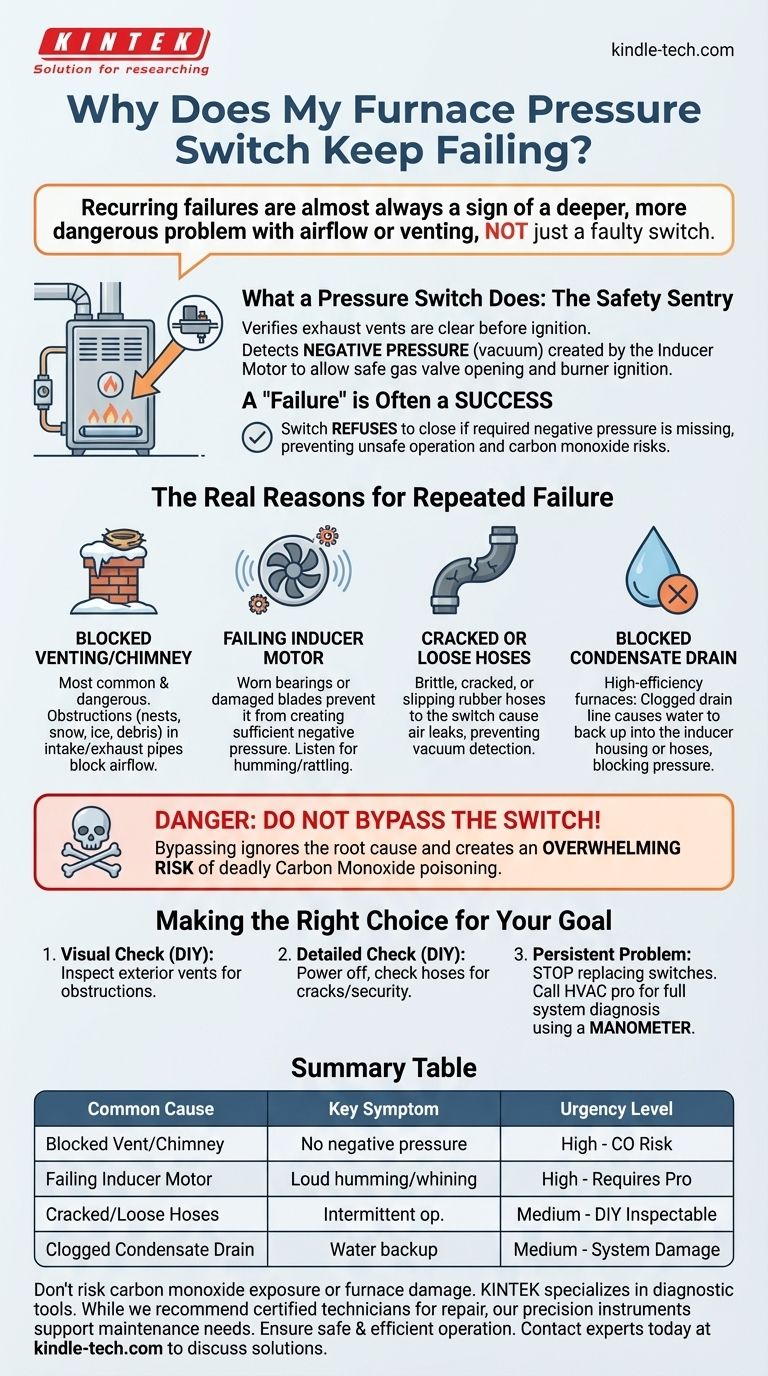

In most cases, a furnace pressure switch that repeatedly fails is not the actual problem. While the switch itself can break down due to an internal ruptured diaphragm, recurring issues almost always indicate a deeper problem within your furnace's venting or combustion air system. The switch is a safety device, and its failure to operate is a critical signal that your furnace cannot run safely.

A recurring pressure switch failure is a critical warning sign. The switch itself is rarely the root cause; it is a safety device indicating a deeper, often dangerous, problem with your furnace's airflow or venting system.

What a Pressure Switch Actually Does

To diagnose the problem, you must first understand the part's function. It is not an operational component but a crucial safety guard.

A Safety Sentry for Your Furnace

The pressure switch is a simple "go/no-go" device. Its only job is to confirm that your furnace's exhaust vents are clear before allowing the main gas valve to open and the burners to ignite.

This prevents toxic exhaust gases, including carbon monoxide, from entering your home.

How It Works: Negative Pressure

When you turn on the heat, the first thing that happens is the inducer motor (a small fan) starts up. Its job is to pull air through the combustion chamber and push exhaust gases safely outside.

This process creates a slight vacuum, or negative pressure, inside the system. The pressure switch is designed to detect this specific negative pressure. When the correct vacuum is achieved, it closes an internal electrical circuit, sending the "all clear" signal to the furnace's control board to proceed with ignition.

A "Failure" is Often a Success

When a pressure switch "fails," it usually means it has not detected the required negative pressure and is therefore refusing to close the circuit.

In this context, the switch is working perfectly. It is successfully preventing your furnace from operating in an unsafe condition. The real problem is whatever is preventing the correct pressure from building in the first place.

The Real Reasons Your Pressure Switch Fails to Close

If you have replaced the switch and the problem persists, the cause is almost certainly one of the following external issues.

Blocked Venting or Chimney

This is the most common and most dangerous cause. Any obstruction in the furnace's intake or exhaust pipes (the PVC pipes leading outside) will prevent the inducer motor from establishing proper airflow.

Common blockages include bird or rodent nests, leaves, heavy snow, or ice buildup over the vent terminations.

A Failing Inducer Motor

The inducer motor itself may be wearing out. If its bearings are failing or the fan blades are damaged, it may not spin fast enough to generate the negative pressure required to activate the switch.

You might hear a loud humming, rattling, or whining sound from the motor before it fails completely.

Cracked or Loose Hoses

The pressure switch is connected to the inducer motor assembly by one or two small rubber or silicone hoses. Over time, this tubing can become brittle, crack, or slip off its connection port.

Even a tiny leak in this hose will prevent the switch from sensing the full vacuum, causing it to remain open.

Blocked Condensate Drain

High-efficiency furnaces produce acidic water (condensate) as a byproduct of combustion. This water is supposed to drain away through a dedicated line.

If this drain line becomes clogged, water can back up into the inducer motor housing and even the pressure switch hoses. This trapped water will block the pressure differential and prevent the switch from closing.

Understanding the Trade-offs: Do Not Bypass the Switch

When faced with a no-heat situation, it can be tempting to look for a quick fix. However, bypassing a pressure switch is exceptionally dangerous and should never be done.

The Overwhelming Risk of Carbon Monoxide

The pressure switch is your primary defense against venting failures. If you bypass it while a vent is blocked, you are allowing the furnace to run while pumping its exhaust fumes, including deadly carbon monoxide, directly into your home.

Masking a Deeper, More Expensive Problem

Bypassing the switch also ignores the underlying issue. Continuing to run a furnace with a failing inducer motor or a blocked drain line will inevitably lead to more significant and costly component failures.

Making the Right Choice for Your Goal

Troubleshooting a recurring pressure switch fault means looking at the entire system, not just the switch.

- If your primary focus is a safe, initial check: Visually inspect the exterior vent pipes for any obvious obstructions like snow, ice, or debris. A simple check can sometimes solve the entire problem.

- If you are comfortable with a more detailed inspection: Power off the furnace, open the main panel, and gently inspect the small rubber hoses connected to the pressure switch. Ensure they are securely attached and look for any cracks or brittleness.

- If the problem persists after multiple switch replacements: Stop replacing the switch. Call a qualified HVAC technician and insist they perform a full system diagnosis using a manometer to measure the actual vacuum pressure. This is the only way to definitively identify the root cause.

By treating the pressure switch as a messenger, you can solve the root cause of the failure and ensure your furnace operates both safely and reliably.

Summary Table:

| Common Cause of Failure | Key Symptom | Urgency Level |

|---|---|---|

| Blocked Vent/Chimney | No negative pressure build-up | High - Risk of CO |

| Failing Inducer Motor | Loud humming or whining sounds | High - Requires professional repair |

| Cracked/Loose Hoses | Intermittent switch operation | Medium - DIY inspectable |

| Clogged Condensate Drain | Water backup in inducer housing | Medium - Can cause system damage |

Don't risk carbon monoxide exposure or further damage to your furnace. If your pressure switch is failing repeatedly, it's a critical sign of a deeper system issue.

KINTEK specializes in lab equipment and consumables, including maintenance tools for HVAC diagnostics. While we recommend a certified HVAC technician for furnace repairs, our precision instruments can support your facility's broader maintenance needs.

Ensure your entire lab or facility operates safely and efficiently. Contact our experts today to discuss reliable equipment solutions for your laboratory environment.

Visual Guide

Related Products

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What is the purpose of graphite paper in SPS? Optimize Nickel Alloy Sintering & Protect Your Mold

- What are the parts that go to a furnace? A Guide to the Three Core Systems

- What is the importance of a vacuum pump for Schottky hybrid interfaces? Achieve Atomic-Level Purity and Bonding

- Why are zirconia grinding jars and balls preferred for recycled graphite? Optimize Purity and Efficiency

- Why is a programmable temperature controller necessary during the annealing process of manganese coatings?

- What is the purpose of a gas bubbler system for BZY20 ceramics? Unlocking Proton Conduction Performance

- What is the maximum pressure for a vacuum pump? Understanding Ultimate Vacuum for Your Lab Needs

- Why is a resistance heating system with a precision temperature controller necessary for steel alloy corrosion experiments?