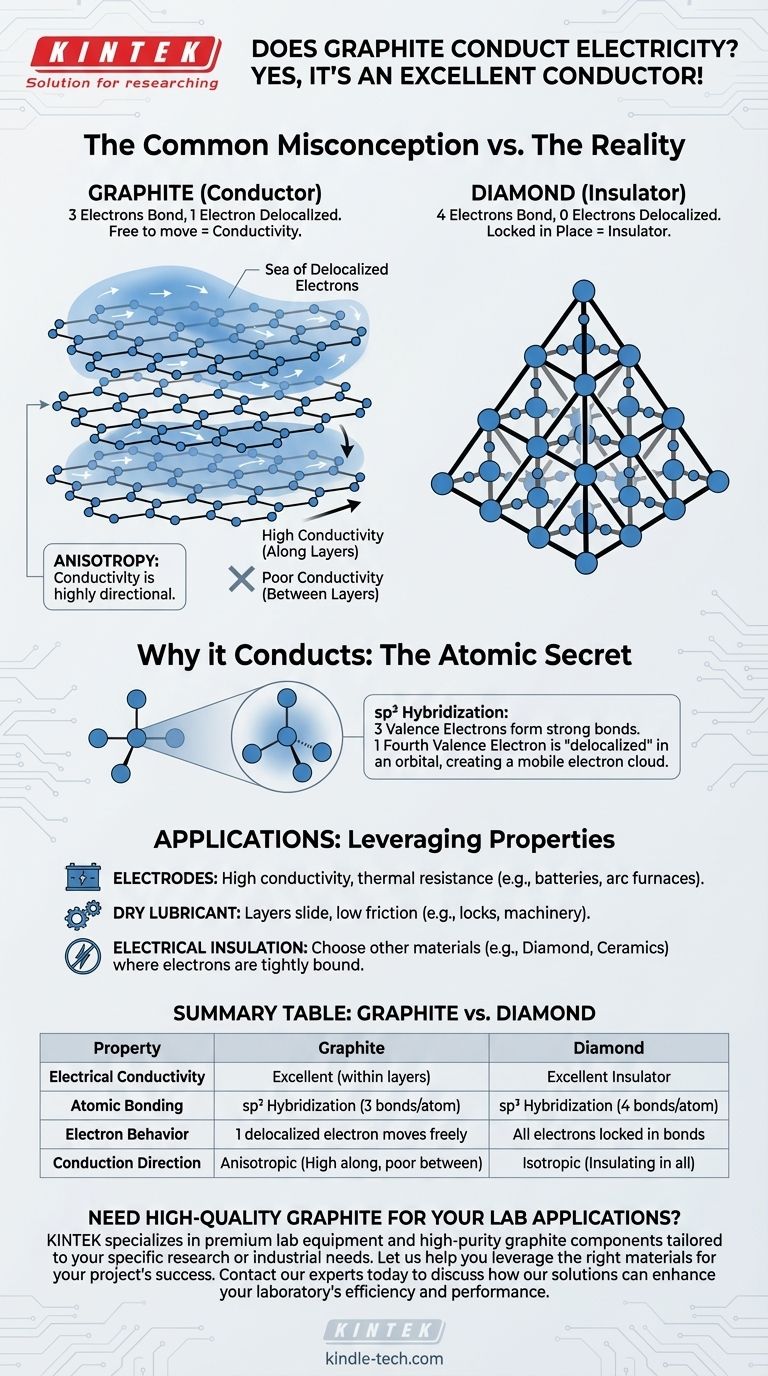

On the contrary, your premise is a common and understandable misconception. Graphite is a non-metal, but it is an excellent conductor of electricity. Its ability to conduct is a direct result of its unique atomic structure, which leaves some electrons free to move and carry an electrical current.

The core reason graphite conducts electricity is its layered structure. Within each layer, every carbon atom uses only three of its four outer electrons for bonding, leaving the fourth electron "delocalized" and free to move throughout the layer, creating a mobile sea of electrons that can carry a charge.

The Foundation: Carbon's Allotropes

To understand graphite, we must first understand carbon. Allotropes are different structural forms of the same element, and these different structures give them vastly different properties.

### What is an Allotrope?

An allotrope is a specific physical form an element can take. For carbon, the two most famous allotropes are diamond and graphite.

Though both are made of pure carbon, their atoms are arranged differently. This difference in atomic arrangement is the sole reason one is the hardest known natural material and an insulator (diamond), while the other is soft, slippery, and an electrical conductor (graphite).

The Atomic Reason for Graphite's Conductivity

The explanation lies in how each carbon atom bonds with its neighbors. A carbon atom has four outer electrons (valence electrons) available for bonding.

### The sp² Bonding in Graphite

In graphite, each carbon atom uses three of its four valence electrons to form strong covalent bonds with three other carbon atoms.

This bonding pattern, known as sp² hybridization, results in a flat plane of carbon atoms arranged in interconnected hexagons. This forms a single sheet we now know as graphene.

### The Key: Delocalized Electrons

The crucial part is what happens to the fourth valence electron. This electron is not used in the strong in-plane bonds.

Instead, this electron resides in an orbital above and below the plane of the carbon sheet. These orbitals from all the atoms in the layer overlap, creating a continuous "cloud" or sea of delocalized electrons.

Because these electrons are not tied to any single atom, they are free to move anywhere along the two-dimensional sheet. When a voltage is applied, these mobile electrons flow, creating an electrical current.

### A Contrast: The Structure of Diamond

In diamond, each carbon atom uses all four of its valence electrons to bond with four other carbon atoms in a rigid, three-dimensional tetrahedral lattice. This is called sp³ hybridization.

Since all electrons are locked into strong covalent bonds, there are no free or delocalized electrons available to move. This is why diamond is a superb electrical insulator.

Understanding the Trade-offs: Anisotropy

Graphite's conductivity is not uniform in all directions. This directional dependence of a property is called anisotropy.

### High Conductivity Along the Layers

Graphite conducts electricity extremely well parallel to its carbon sheets. This is because the delocalized electrons can move freely and rapidly along these two-dimensional planes.

### Poor Conductivity Between Layers

The individual sheets of graphite are stacked on top of each other and held together by very weak forces (van der Waals forces). There are no strong bonds or electron pathways between the layers.

As a result, electrons cannot easily jump from one layer to the next. This makes graphite a poor conductor of electricity in the direction perpendicular to its sheets.

How This Applies to Your Project

Understanding this principle allows you to select the right material for the job, as graphite's unique properties make it suitable for very specific applications.

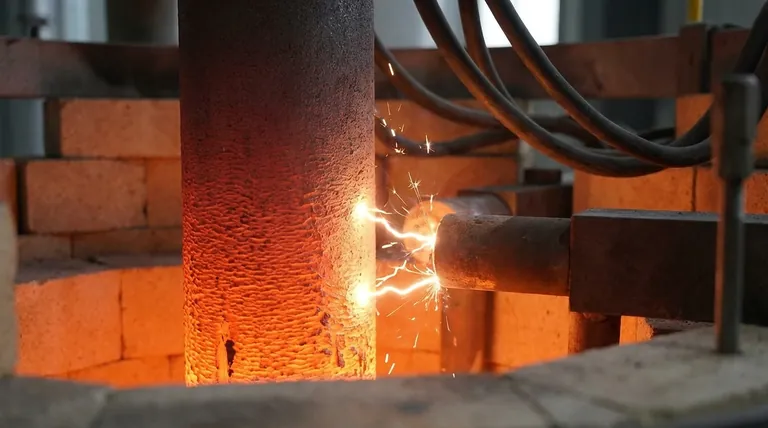

- If your primary focus is creating an electrode: Graphite is an ideal choice due to its high electrical conductivity, low cost, and ability to withstand extreme heat, making it perfect for arc furnaces and batteries.

- If your primary focus is finding a dry lubricant: The weak bonds between graphite's layers allow them to slide past one another with very little force, making it an excellent solid lubricant for locks or high-temperature machinery.

- If your primary focus is electrical insulation: You must choose a different material. Other carbon allotropes like diamond, or more practical materials like ceramics and polymers, are used because their electrons are tightly bound.

Ultimately, a material's electrical properties are dictated by the freedom of its electrons, a direct consequence of its atomic structure.

Summary Table:

| Property | Graphite | Diamond |

|---|---|---|

| Electrical Conductivity | Excellent conductor (within layers) | Excellent insulator |

| Atomic Bonding | sp² hybridization (3 bonds per atom) | sp³ hybridization (4 bonds per atom) |

| Electron Behavior | 1 delocalized electron per atom moves freely | All electrons locked in covalent bonds |

| Conduction Direction | Anisotropic (high along layers, poor between layers) | Isotropic (insulating in all directions) |

Need High-Quality Graphite for Your Lab Applications?

Graphite's unique conductivity and thermal stability make it ideal for electrodes, high-temperature furnaces, and specialized lab equipment. At KINTEK, we specialize in providing premium lab equipment and consumables, including high-purity graphite components tailored to your specific research or industrial needs.

Let us help you leverage the right materials for your project's success. Contact our experts today to discuss how our solutions can enhance your laboratory's efficiency and performance.

Visual Guide

Related Products

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Is glass made by sintering? The Truth About How Glass is Formed

- What are laser sintering methods? Unlock Complex 3D Printing with Powder Bed Fusion

- What is the difference between sintering and melting temperature? Choosing the Right Thermal Process for Your Materials

- What temperature should a furnace run at? From Home Comfort to Industrial Processes

- How does a magnetic stirrer influence the efficiency of the sulfuric acid leaching process for zinc ash? Expert Insights

- What is the difference between VAR and ESR? A Guide to Understanding Tail Risk in Financial Modeling

- How do ULT freezers improve the storage life of medical components? Extend Sample Viability for Years

- What are the technical advantages of using an industrial electric stirrer for ZrO2 and PMMA? Enhance Shielding Uniformity