In short, high frequency is used in an induction furnace to control where the heat is generated. By increasing the frequency, the induced electrical current is forced to flow in a thin layer near the surface of the metal. This phenomenon, known as the "skin effect," creates intense, rapid, and highly efficient heating, which is ideal for melting smaller charges and for applications demanding precise control over the metallurgy.

The choice of frequency in an induction furnace is the primary control for determining the depth of heat penetration. High frequency creates shallow, concentrated surface heating, while low frequency enables deep, uniform heating through the core of large materials.

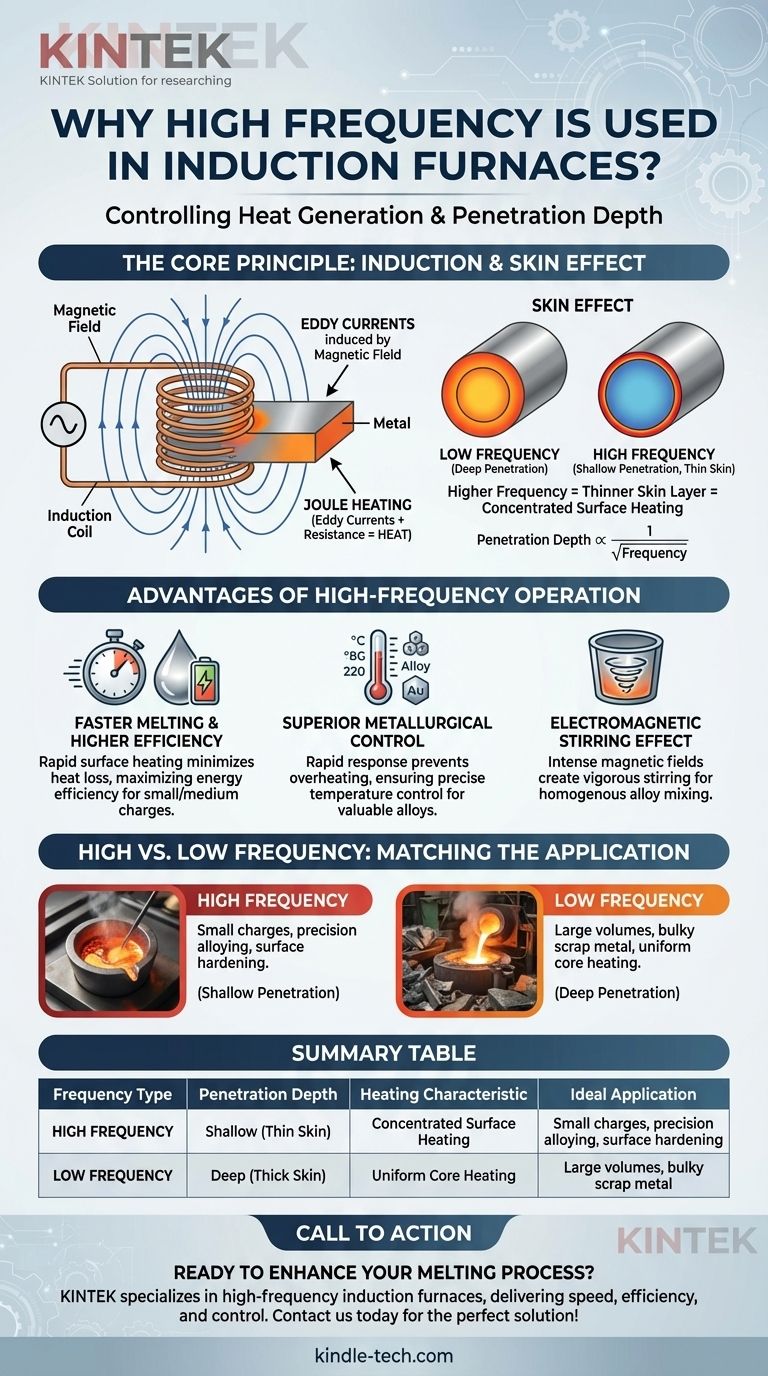

The Core Principle: Induction and the Skin Effect

To understand the role of frequency, we must first grasp the fundamental physics at play. The process is not about external flames or arcs; the heat is generated within the metal itself.

How Induction Heating Works

An induction furnace uses a powerful alternating current (AC) flowing through a copper coil. This coil generates a rapidly changing and intense magnetic field around the metal charge placed inside it.

According to Faraday's Law of Induction, this changing magnetic field induces powerful, swirling electrical currents within the metal. These are known as eddy currents.

The Role of Eddy Currents in Heating

As these strong eddy currents flow through the metal, they encounter electrical resistance. This resistance converts the electrical energy directly into heat—a principle known as Joule heating. This is the same effect that makes a standard light bulb's filament glow.

Introducing the Skin Effect

Crucially, alternating current does not flow uniformly through a conductor. The current density is highest at the surface and decreases exponentially toward the center. This is called the skin effect.

The higher the frequency of the alternating current, the more pronounced this effect becomes, forcing the eddy currents into an even thinner layer at the surface.

How Frequency Governs Penetration Depth

This relationship is the key. The penetration depth of the current is inversely proportional to the square root of the frequency.

In simple terms:

- High Frequency = Small penetration depth (thin skin) = Concentrated surface heating.

- Low Frequency = Large penetration depth (thick skin) = Deeper, more uniform heating.

Advantages of High-Frequency Operation

For many applications, concentrating heat on the surface is a significant advantage, directly contributing to the benefits mentioned in your research.

Faster Melting and Higher Efficiency

By focusing all the energy into a small surface volume, high-frequency furnaces can melt small to medium-sized charges incredibly quickly. This speed minimizes the time for heat to be lost to the surroundings, resulting in higher overall energy efficiency.

Superior Metallurgical Control

The rapid response of a high-frequency system allows for extremely precise temperature control. This is critical when working with valuable alloys, as it prevents overheating and the subsequent loss or "burn-off" of these expensive elements.

The Electromagnetic Stirring Effect

The intense magnetic fields also create a strong stirring action within the molten metal bath. At higher frequencies, this stirring is vigorous and ensures that added alloys are mixed in quickly and evenly, resulting in a homogenous final product.

Understanding the Trade-offs: It's Not Always the Best Choice

While powerful, high frequency is not a universal solution. The choice of frequency is a critical engineering decision based on the specific application.

When Low Frequency is Better

For very large furnaces designed to melt large, chunky scrap metal, high frequency would be ineffective. It would melt the surface of the scrap long before the core could get hot. In these cases, a low-frequency (or mains frequency) current is used to ensure the induced current penetrates deeply, heating the entire charge more uniformly.

Power Supply Complexity

Generating high-frequency power requires more sophisticated and often more expensive solid-state power supplies compared to the simpler transformers used for low-frequency applications.

Matching Frequency to Application

The goal is to match the penetration depth to the size of the material being melted. The optimal frequency creates a balance between rapid heating, efficient energy transfer, and the desired metallurgical outcome.

Making the Right Choice for Your Goal

Ultimately, the frequency is selected to match the task at hand, balancing speed, efficiency, and the scale of the operation.

- If your primary focus is rapid melting of small charges or precision alloying: High frequency is the superior choice for its speed and control.

- If your primary focus is surface hardening or case hardening a part: High frequency is essential to heat only the surface without affecting the core's properties.

- If your primary focus is melting very large volumes or large, solid pieces of scrap: Low frequency is necessary to achieve the deep heat penetration required for an effective melt.

Understanding how frequency dictates heat penetration empowers you to control the melting process with remarkable precision.

Summary Table:

| Frequency Type | Penetration Depth | Heating Characteristic | Ideal Application |

|---|---|---|---|

| High Frequency | Shallow (Thin Skin) | Concentrated Surface Heating | Small charges, precision alloying, surface hardening |

| Low Frequency | Deep (Thick Skin) | Uniform Core Heating | Large volumes, bulky scrap metal |

Ready to enhance your melting process with precision heating? KINTEK specializes in high-frequency induction furnaces and lab equipment, delivering the speed, efficiency, and metallurgical control your laboratory needs. Contact us today to find the perfect solution for your application!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are the advantages of using an alumina liner in a tube furnace for biomass combustion corrosion simulations?

- How does an alumina tube furnace with a controlled atmosphere simulate conditions in CSP environments? Master Accuracy.

- What factors influence the general design of a tube furnace? Match Your Process with the Perfect System

- How do you clean a tube furnace tube? A Step-by-Step Guide to Safe and Effective Cleaning

- What tube is used for tubular furnace? Choose the Right Material for Temperature & Atmosphere