In short, hydrogen gas is used in annealing because it serves as a powerful reducing agent and creates a highly pure, protective atmosphere. It actively removes surface oxides and other impurities from the metal while simultaneously preventing new oxidation from occurring at high temperatures, resulting in a clean, bright surface and superior material properties.

The core purpose of using a hydrogen atmosphere is to control the chemical environment during heat treatment. Unlike inert gases that merely prevent oxidation, hydrogen actively purifies the metal's surface by chemically stripping away oxygen, ensuring the final product meets the highest standards for strength and finish.

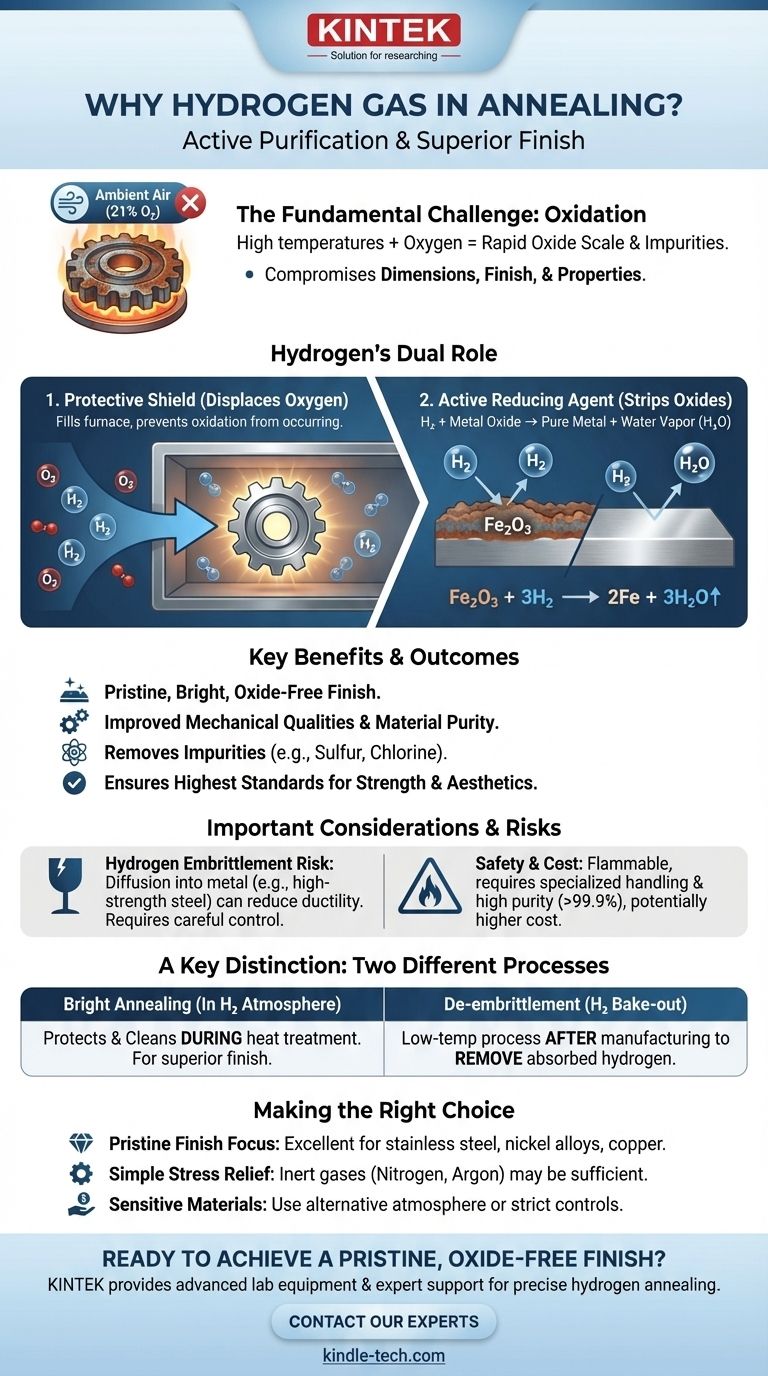

The Fundamental Challenge: Oxidation at High Temperatures

Why a Protective Atmosphere is Necessary

Annealing requires heating metals to high temperatures to relieve internal stresses and improve ductility. When heated in the presence of ambient air, which contains about 21% oxygen, most metals will rapidly oxidize.

This oxidation forms a layer of scale on the surface. This scale is undesirable as it can compromise the part's dimensions, surface finish, and subsequent processing steps like coating or welding.

The Goal: A Pristine Surface

The primary goal of using a specialized atmosphere is to prevent this oxidation. This ensures the material's surface remains clean, bright, and free of defects after the heat treatment cycle is complete.

Hydrogen's Dual Role: Protector and Purifier

1. As a Protective Atmosphere

By filling the furnace chamber with high-purity hydrogen, all oxygen is displaced. With no oxygen present, the fundamental chemical reaction of oxidation cannot occur, effectively protecting the metal from scaling as its temperature rises.

2. As an Active Reducing Agent

This is what makes hydrogen uniquely powerful compared to inert gases like argon or nitrogen. Hydrogen doesn't just passively protect the metal; it actively cleans it.

If any surface oxides are already present on the part before annealing, the hydrogen gas will react with them. The hydrogen effectively "steals" the oxygen atoms from the metal oxide, forming water vapor (H₂O) which is then vented from the furnace. This chemical reduction process leaves behind a pure, unoxidized metal surface.

3. Removing Other Impurities

Hydrogen's role as a scavenger isn't limited to oxygen. It can also react with and remove other non-metallic impurities, such as trace amounts of sulfur or residual chlorine from previous processes. This leads to a cleaner alloy with improved mechanical qualities.

Understanding the Trade-offs and Risks

The Risk of Hydrogen Embrittlement

While excellent as an external atmosphere, hydrogen can be detrimental if it diffuses into the atomic structure of certain metals, particularly high-strength steels. This phenomenon, known as hydrogen embrittlement, can severely reduce the material's ductility and make it brittle.

Careful control over temperature and cycle time is critical to prevent hydrogen from being absorbed by susceptible materials.

Safety and Handling

Hydrogen is extremely flammable and can form explosive mixtures with air. Facilities using hydrogen for annealing require specialized storage, rigorous safety protocols, and advanced furnace systems designed to handle the gas safely.

Cost and Purity

The process often requires very high-purity hydrogen (>99.9%) to be effective, which can be more expensive than using other atmospheres like nitrogen or dissociated ammonia. The cost must be justified by the need for a superior surface finish and material purity.

A Key Distinction: Annealing in Hydrogen vs. Annealing to Remove Hydrogen

It is critical to distinguish between two different processes that both involve "hydrogen" and "annealing."

Bright Annealing in a Hydrogen Atmosphere

This is the process described above, where hydrogen is intentionally used as the atmosphere to protect and clean the part during heat treatment.

De-embrittlement Annealing (Hydrogen Bake-out)

This is a separate, low-temperature process (e.g., 200-300°C) performed after manufacturing steps like welding, plating, or galvanizing. These processes can unintentionally introduce hydrogen into the metal. The purpose of this annealing cycle is to use heat to drive the trapped hydrogen out of the material to prevent hydrogen embrittlement.

Making the Right Choice for Your Process

- If your primary focus is achieving a pristine, bright, oxide-free surface: Hydrogen is an excellent choice for its active reducing properties, especially for stainless steels, nickel alloys, and copper.

- If your primary focus is simple stress relief on non-sensitive materials: A less expensive and safer inert gas like nitrogen or an argon blend may be a more practical and sufficient choice.

- If you are working with materials susceptible to hydrogen embrittlement: You must either use an alternative atmosphere or implement strict process controls to mitigate the risk of hydrogen absorption.

- If you are treating parts after welding or electroplating: A low-temperature "bake-out" anneal may be required specifically to remove absorbed hydrogen and prevent material failure.

Ultimately, choosing hydrogen is a decision to invest in active chemical control during heat treatment for a superior, purified final product.

Summary Table:

| Role of Hydrogen | Key Benefit |

|---|---|

| Protective Atmosphere | Displaces oxygen to prevent surface oxidation (scaling). |

| Active Reducing Agent | Chemically removes existing surface oxides, forming water vapor. |

| Impurity Scavenger | Helps remove other contaminants like sulfur for a cleaner alloy. |

| Result | A bright, clean surface with improved mechanical properties. |

Ready to achieve a pristine, oxide-free finish on your critical metal components?

KINTEK specializes in providing the advanced lab equipment and expert support needed for precise hydrogen annealing processes. Our solutions help you leverage hydrogen's reducing power safely and effectively, ensuring superior material quality for your laboratory's most demanding applications.

Contact our experts today to discuss your specific annealing requirements and discover how we can enhance your heat treatment outcomes.

Visual Guide

Related Products

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Vertical Laboratory Tube Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What is an inert atmosphere? Protect Materials and Enhance Quality with Controlled Environments

- What is the role of an Atmosphere Furnace in the preparation of lignin-based graphene oxide? Key Carbonization Insights

- Why is atmosphere control essential during the pyrolysis of silicone composites? Ensure High-Density Ceramic Integrity

- What is a reducing atmosphere? Key Applications and Benefits for Industrial Processes

- Why is atmosphere-protected heating equipment necessary for Pyr-IHF? Achieve Precision in Material Synthesis

- How does an atmosphere furnace facilitate the post-treatment of nickel-plated carbon fibers? Ensure Peak Bonding

- What is the function of a high-temperature atmosphere furnace in the heat treatment of 300M steel? Achieve Precision

- Why is a high-temperature atmosphere furnace used for 850°C heat treatment of FeCrAl? Enhance Material Reliability