In forging, temperature is the single most critical variable for success. Increasing the temperature of a metal makes it significantly softer and more malleable, allowing it to be shaped with less force and without risk of fracture. This process, known as hot forging, also fundamentally improves the material's internal structure, resulting in a finished component with superior strength and durability.

The core purpose of heating for forging is to bring the metal into its "plastic" state—a temperature window where its crystal structure can be reshaped and refined simultaneously. Operating outside this optimal window, either too hot or too cold, compromises the integrity of the material and can lead to catastrophic failure.

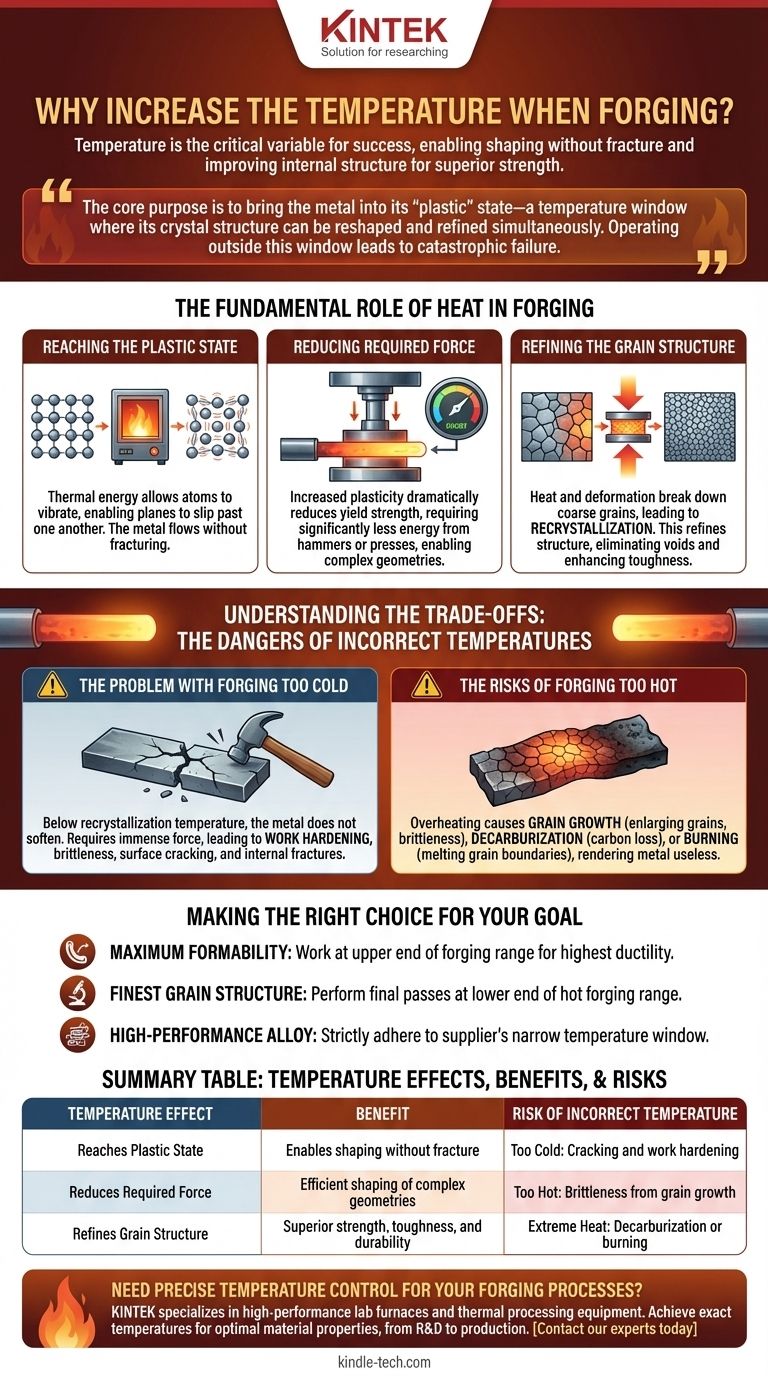

The Fundamental Role of Heat in Forging

Heating a metal workpiece to a specific temperature is not just about making it soft. It's a precise metallurgical process designed to unlock the material's potential for both shaping and structural improvement.

Reaching the Plastic State

Metals are crystalline solids. At room temperature, their atomic structure is rigid, and attempting to deform them excessively will cause them to crack or break.

Heating provides thermal energy, allowing the atoms within this crystal lattice to vibrate and move more freely. This enables planes of atoms to slip past one another under pressure, a phenomenon known as plastic deformation. The metal can now flow like a highly viscous fluid without fracturing.

Reducing Required Force

A direct consequence of increased plasticity is a dramatic reduction in the material's yield strength.

This means significantly less energy is required from hammers, presses, or rollers to shape the workpiece. This makes the forging process more efficient, faster, and allows for the creation of more complex geometries that would be impossible with cold metal.

Refining the Grain Structure

Perhaps the most important benefit of hot forging is its effect on the metal's internal grain structure. Most raw metals have large, inconsistent grains, which can be points of weakness.

The combination of heat and deformation force breaks down these coarse grains. As the metal cools, a new, finer, and more uniform grain structure forms in a process called recrystallization. This refined structure eliminates internal voids and enhances mechanical properties like toughness, ductility, and fatigue resistance.

Understanding the Trade-offs: The Dangers of Incorrect Temperatures

The forging temperature is not a single point but a carefully controlled range. Deviating from this range introduces severe risks.

The Problem with Forging Too Cold

If the metal is not hot enough—below its recrystallization temperature—it will not soften sufficiently.

Attempting to forge in this state requires immense force and can induce work hardening, making the material brittle. This leads to a high risk of surface cracking and internal fractures, compromising the part's structural integrity.

The Risks of Forging Too Hot

Overheating the workpiece is even more dangerous and can cause irreversible damage.

Excessively high temperatures lead to rapid grain growth, where the refined grains begin to enlarge and coalesce, making the material brittle and weak. For steels, it can also cause decarburization (loss of carbon from the surface) or, in the worst case, burning, where the grain boundaries begin to melt, rendering the metal completely useless.

Making the Right Choice for Your Goal

Selecting the correct temperature is a critical decision based on the specific alloy and the desired mechanical properties of the final component.

- If your primary focus is maximum formability: Work within the upper end of the prescribed forging range to ensure the highest ductility and lowest resistance to shaping.

- If your primary focus is the finest grain structure: Perform the final forging passes at the lower end of the hot forging range to promote recrystallization without risking excessive grain growth.

- If you are working with a high-performance alloy: Strictly adhere to the material supplier's specified temperature window, as these materials have very narrow ranges for optimal results.

Ultimately, mastering temperature control is what transforms a simple piece of metal into a resilient, high-performance component.

Summary Table:

| Temperature Effect | Benefit | Risk of Incorrect Temperature |

|---|---|---|

| Reaches Plastic State | Enables shaping without fracture | Too Cold: Cracking and work hardening |

| Reduces Required Force | Efficient shaping of complex geometries | Too Hot: Brittleness from grain growth |

| Refines Grain Structure | Superior strength, toughness, and durability | Extreme Heat: Decarburization or burning |

Need precise temperature control for your forging or heat treatment processes? KINTEK specializes in high-performance lab furnaces and thermal processing equipment designed for metallurgical applications. Our solutions ensure you achieve the exact temperatures required for optimal material properties, from R&D to production.

Contact our experts today to discuss how our equipment can help you forge stronger, more reliable components.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- Can you use a heat press for transfers? The Definitive Tool for Professional Results

- Why is a laboratory hot press necessary for all-solid-state battery assembly? Reduce Impedance and Enhance Performance

- How does a high-pressure heating press enhance fluoroplastic-carbon nanotube composites? Boost Strength by 20%

- What are the primary challenges in hot press platen temperature control? Expert Thermal Efficiency Guide

- How does a laboratory hot press improve alloy performance? Optimize Liquid Phase Sintering for High-Strength Materials

- What is a veneer press? Achieve a Perfect, Delamination-Free Bond

- What is the role of a laboratory-grade heated hydraulic press in MEA fabrication? Optimize Fuel Cell Performance

- What are the different types of hot plates? Find the Perfect Match for Your Lab's Heating Needs