In short, pressing force is critical in sintering because it fundamentally changes how material particles bond together. Unlike conventional sintering which relies solely on heat to slowly diffuse material, the added pressure mechanically breaks down surface barriers, forces particles into intimate contact, and activates rapid densification mechanisms like plastic flow. This results in a denser, stronger final part, often achieved at lower temperatures and in less time.

The core challenge in sintering is achieving full density without excessive grain growth. Applying external pressure isn't just an enhancement; it introduces entirely new physical mechanisms that accelerate pore closure, making it possible to densify materials that are difficult or impossible to sinter with heat alone.

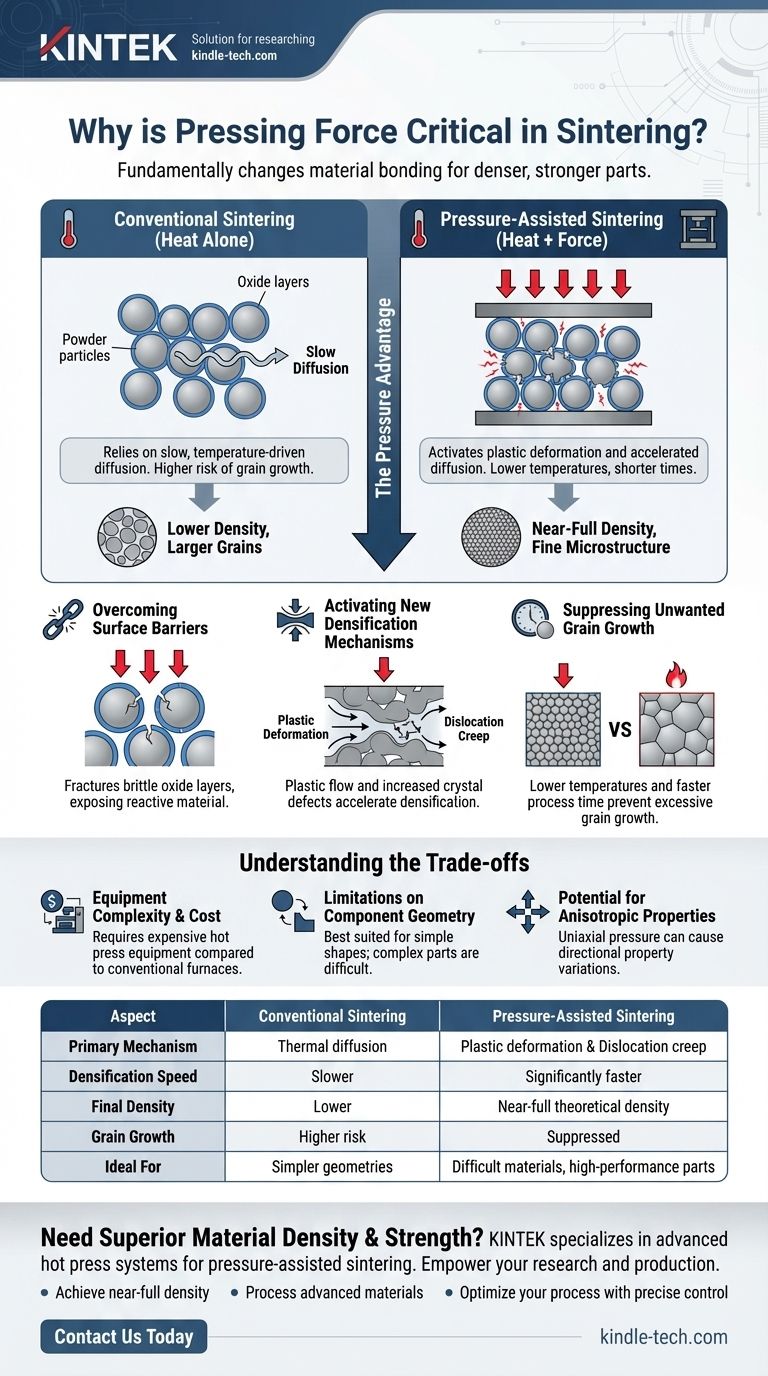

How Pressing Force Fundamentally Changes Sintering

Conventional sintering and pressure-assisted sintering (like hot pressing) start with the same goal but take very different paths. The application of force is the key differentiator that alters the process at a microscopic level.

Overcoming Surface Barriers

All powder particles have a thin, passive surface layer, typically an oxide. This film acts as a barrier, preventing the clean, metal-to-metal contact needed for strong diffusion bonding.

Pressure physically fractures these brittle oxide layers. This exposes the pure, highly reactive material underneath, creating a direct pathway for atoms to move between particles and form strong bonds.

Activating New Densification Mechanisms

In conventional sintering, densification relies on slow, temperature-driven diffusion. Pressure introduces a much faster mechanism: plastic deformation.

The force literally squeezes the material, causing it to flow and deform to fill the void spaces (pores) between particles. This is far more efficient at eliminating porosity than waiting for atoms to diffuse one by one.

Furthermore, pressure increases the concentration of crystal defects, such as dislocations. These defects act as high-speed "highways" for atomic diffusion, a process known as dislocation creep, which further accelerates densification.

Suppressing Unwanted Grain Growth

A common problem in sintering is that as you increase temperature to close pores, the material's grains also grow larger, which can weaken the final product.

Because pressure accelerates densification so effectively, the process can be completed at lower temperatures or for shorter times. This gives the grains less opportunity to grow, allowing you to achieve a final part that is both dense and has a fine, strong microstructure.

Understanding the Trade-offs

While powerful, applying pressure is not a universal solution. It introduces specific constraints and complexities that must be considered.

Equipment Complexity and Cost

Pressure-assisted sintering requires a hot press, a specialized and expensive piece of equipment capable of applying high loads at extreme temperatures in a controlled atmosphere or vacuum. This is a significant investment compared to a conventional furnace.

Limitations on Component Geometry

The process is inherently limited by the die that contains the powder. This means hot pressing is best suited for producing relatively simple shapes, such as discs, blocks, or cylinders. Complex, near-net-shape parts are very difficult to produce.

Potential for Anisotropic Properties

The pressure is applied along a single axis (uniaxially). This can cause the material's microstructure and, consequently, its mechanical properties to become anisotropic—meaning they are different in the direction of pressing compared to the directions perpendicular to it.

Making the Right Choice for Your Goal

The decision to use pressure depends entirely on your material and desired outcome.

- If your primary focus is achieving near-full theoretical density: Hot pressing is the superior method, as it actively eliminates porosity through plastic flow.

- If your primary focus is processing difficult-to-sinter materials (e.g., covalent ceramics like silicon carbide): The force is essential to break strong bonds and activate densification where thermal energy alone is insufficient.

- If your primary focus is preserving a fine-grained microstructure for superior mechanical properties: The lower temperatures and shorter times enabled by pressure are critical to preventing unwanted grain growth.

Ultimately, using pressing force gives you a powerful lever to control the densification process far beyond what heat alone can offer.

Summary Table:

| Aspect | Conventional Sintering | Pressure-Assisted Sintering |

|---|---|---|

| Primary Mechanism | Thermal diffusion | Plastic deformation & dislocation creep |

| Densification Speed | Slower | Significantly faster |

| Final Density | Lower | Near-full theoretical density |

| Grain Growth | Higher risk at elevated temperatures | Suppressed (lower temps/shorter times) |

| Ideal For | Simpler geometries, less demanding applications | Difficult-to-sinter materials, high-performance parts |

Need to achieve superior material density and strength?

At KINTEK, we specialize in advanced lab equipment, including hot press systems for pressure-assisted sintering. Our solutions are designed to help you overcome the limitations of conventional sintering, enabling you to process difficult materials and produce high-performance, dense components with fine microstructures.

Let KINTEK empower your research and production:

- Achieve near-full density for stronger, more reliable parts.

- Process advanced materials like covalent ceramics that are hard to sinter with heat alone.

- Optimize your process with equipment capable of precise temperature and pressure control.

Contact our experts today to discuss how our sintering solutions can meet your specific laboratory needs. #Contact Us Today

Visual Guide

Related Products

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- Why is a vacuum hot press furnace required for sintering copper-based diamond composites? Achieve Maximum Density

- What is the function of a vacuum hot press furnace? Achieve High Densification in Al-Ti-Zr Synthesis

- What physical process occurs to materials inside a vacuum hot pressing furnace? Achieve Full Densification for Superior Materials

- Why is precise temperature control necessary for SiC/Cu Vacuum Hot Pressing? Mastering the Cu9Si Interface Phase

- How does the uniaxial pressing function of a vacuum hot press furnace influence the microstructure of ZrC-SiC ceramics?