Understanding the CVD Process

Definition and Applications of CVD

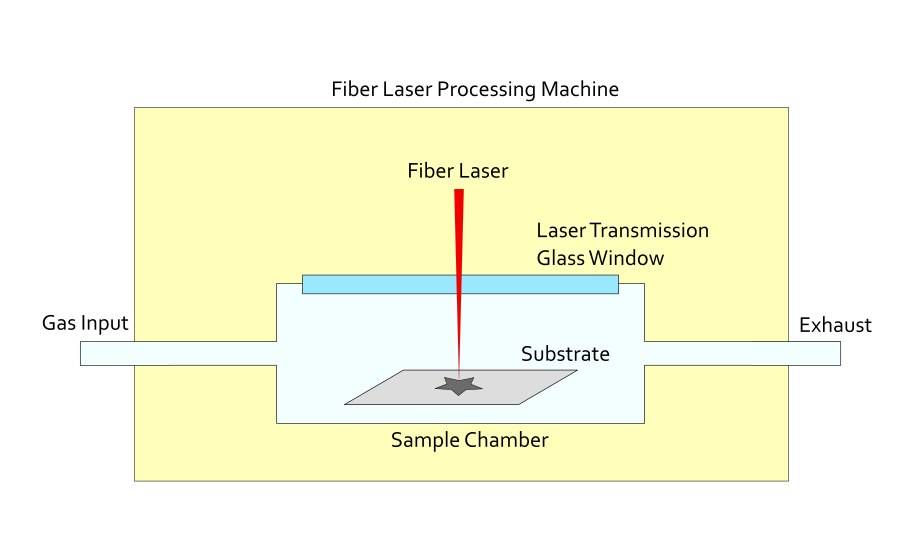

Chemical Vapor Deposition (CVD) is a versatile process technology employed to fabricate a wide array of materials, including semiconductors, ceramics, metals, and alloys. In this process, chemical precursors in gaseous or vapor form undergo a chemical reaction on the surface of a substrate, resulting in the formation of a solid film. This reaction typically occurs at elevated temperatures to ensure the necessary chemical reactivity.

CVD technology holds significant importance in semiconductor manufacturing, where it is instrumental in depositing various types of thin films, such as insulating materials and metals. The process is characterized by its ability to produce films with high purity, ranging from 99.99% to 99.999%, and with densities close to 100%. This high level of precision and control makes CVD indispensable in the fabrication of advanced semiconductor devices.

Moreover, CVD is not limited to semiconductors; it is also widely used in the production of synthetic diamonds and various other materials such as silicon, carbon, nitrides, carbides, and oxides. The versatility of CVD extends to its ability to handle a broad spectrum of materials, both metallic and non-metallic, making it a cornerstone technology in modern material science and engineering.

CVD coatings are particularly valued in applications requiring a smooth surface finish and high resistance to wear and corrosion. In semiconductor manufacturing, CVD is used to deposit critical layers such as silicon dioxide and silicon nitride, ensuring the integrity and performance of the final device. The process's reliance on gaseous reactants allows for precise control over the deposition parameters, contributing to the high reliability and reproducibility of CVD-produced materials.

In summary, CVD's broad applicability, coupled with its ability to produce high-purity, high-density films, makes it an essential technology in both the semiconductor industry and beyond. Its role in enabling the fabrication of complex, high-performance materials underscores its significance in advancing technological frontiers.

High Purity PFA Tubing

Properties and Importance of High Purity PFA Tubing

High purity PFA tubing is a specialized form of tubing crafted from high purity fusible polytetrafluoroethylene (PTFE) resin. This material inherits the exceptional characteristics of PTFE, including its renowned chemical resistance, high temperature resistance spanning from -80℃ to 260℃, and its low coefficient of friction. Additionally, PFA tubing exhibits superior processability, making it a preferred choice for demanding applications.

The paramount purity of Trifluraly's high-purity PFA tubing is a critical attribute, as it effectively mitigates the infiltration of impurities and contaminants. This level of purity is indispensable in semiconductor manufacturing processes, where the stringent requirements for material purity are non-negotiable. The tubing's ability to maintain an uncontaminated environment ensures the integrity and reliability of the materials used in these high-stakes applications.

In summary, the combination of PFA's inherent properties and the enhanced purity of Trifluraly's tubing makes it an essential component in environments where chemical resistance, temperature stability, and purity are paramount. This makes it a cornerstone in the intricate machinery of semiconductor production, where even the slightest impurity can have significant repercussions.

Applications of High Purity PFA Tubing in CVD Processes

Gas Transportation

Due to its exceptional chemical and high-temperature resistance, PFA tubing is uniquely suited as a conduit for transporting gases within the Chemical Vapor Deposition (CVD) process. This application is particularly critical in semiconductor manufacturing, where the gases involved can be highly corrosive or prone to react at elevated temperatures. The inherent properties of PFA tubing, such as its ability to withstand extreme conditions without degrading, make it an indispensable component in ensuring the integrity and purity of the gas transportation process.

In the context of CVD, the gases transported through PFA tubing often include reactive precursors and corrosive by-products. These gases are essential for the formation of thin films on semiconductor substrates, a process that requires precise control over the chemical composition and temperature. The high-purity nature of PFA tubing ensures that these gases remain uncontaminated, preventing any potential impurities from affecting the quality of the deposited films.

Moreover, the use of PFA tubing in gas transportation extends beyond mere resistance to chemicals and heat. It also facilitates a smooth and efficient flow of gases, minimizing pressure drops and ensuring uniform distribution within the reaction chamber. This uniformity is crucial for achieving consistent film deposition, which is a key factor in the production of high-quality semiconductor devices.

In summary, PFA tubing's role in gas transportation within CVD processes is multifaceted, combining robust material properties with the need for high purity and efficiency. This makes it an essential element in maintaining the integrity and performance of semiconductor manufacturing operations.

Reaction Chamber Components

Within the reaction chamber of a Chemical Vapor Deposition (CVD) machine, high-purity PFA tubing plays a crucial role in maintaining the integrity and efficiency of the process. This tubing is often utilized in the construction of key components such as gas distributors, which are essential for ensuring the uniform distribution of reaction gases. The use of high-purity PFA tubing in these components is particularly advantageous due to its exceptional chemical resistance and high-temperature tolerance, which are critical for withstanding the harsh conditions within the reaction chamber.

Moreover, the extreme purity of PFA tubing prevents the infiltration of impurities and contaminants, which is paramount for meeting the stringent purity requirements of semiconductor manufacturing. This ensures that the reaction gases are delivered without any degradation in quality, thereby maintaining the consistency and reliability of the CVD process. In essence, the integration of high-purity PFA tubing into the reaction chamber components not only enhances the efficiency of gas distribution but also contributes to the overall precision and quality of the semiconductor fabrication process.

Chemical Delivery Systems

In semiconductor manufacturing processes, the precise delivery of a variety of chemicals and gases is paramount. High purity PFA tubing stands out as the ideal choice for this critical task due to its unparalleled corrosion resistance and purity. This tubing is made from high purity fusible polytetrafluoroethylene (PTFE) resin, which not only inherits the excellent properties of PTFE—such as chemical resistance, high temperature resistance, and low coefficient of friction—but also offers enhanced processability.

The extreme purity of PFA tubing, such as that provided by Trifluraly, ensures that no impurities or contaminants can penetrate the material. This is crucial for meeting the stringent purity requirements in semiconductor manufacturing. The tubing's ability to maintain its integrity under high temperatures and corrosive environments makes it indispensable for the safe and precise delivery of chemicals and gases.

Moreover, PFA tubing is not only used for gas transportation but also plays a vital role within the reaction chamber of a CVD machine. It can be integrated into components like gas distributors, ensuring the uniform distribution of reaction gases. This uniform distribution is essential for the consistent quality of the deposited films, which is a key factor in the production of high-performance semiconductors.

In summary, high purity PFA tubing is a cornerstone in the chemical delivery systems of semiconductor manufacturing, providing a reliable and contamination-free pathway for the critical materials used in the CVD process.

Ultrapure Liquid Handling

In the Chemical Vapor Deposition (CVD) process, the precise delivery of ultrapure liquids is paramount to ensuring the integrity and performance of the deposited materials. These liquids, often used as precursors or solvents, must be free from any trace impurities that could compromise the quality of the final product. High purity PFA tubing plays a crucial role in this context, offering a clean and contamination-free pathway for these critical fluids.

The significance of PFA tubing in ultrapure liquid handling cannot be overstated. Its material properties, which include exceptional chemical resistance, high temperature stability, and low coefficient of friction, make it the ideal choice for maintaining the purity of liquids throughout their journey from storage to deposition. Moreover, the seamless, non-porous structure of PFA tubing effectively prevents the infiltration of external contaminants, ensuring that the liquids remain in their pristine state.

This level of purity is especially critical in semiconductor manufacturing, where even minute impurities can lead to defects in the deposited layers, affecting the overall performance and reliability of the semiconductor devices. By utilizing high purity PFA tubing, manufacturers can mitigate these risks, thereby enhancing the yield and consistency of their CVD processes.

Waste Disposal Systems

During the Chemical Vapor Deposition (CVD) process, the generation of hazardous wastes is an inevitable byproduct. These wastes, if not managed properly, can lead to significant environmental and operational hazards. High purity PFA tubing plays a crucial role in the safe disposal of these hazardous materials, ensuring that the environment and equipment remain uncontaminated.

PFA tubing's exceptional chemical resistance and high-temperature tolerance make it an ideal choice for handling hazardous wastes. Unlike conventional materials, PFA tubing does not degrade or react with the chemicals present in the waste streams, thereby maintaining its structural integrity and effectiveness over time. This stability is paramount in preventing leaks or failures that could lead to contamination.

Moreover, the extreme purity of PFA tubing ensures that no foreign particles or contaminants are introduced into the waste disposal system. This is particularly important in semiconductor manufacturing, where even trace amounts of impurities can compromise the quality and performance of the final product. By using high purity PFA tubing, manufacturers can be confident that their waste disposal systems are as clean and efficient as possible.

In summary, high purity PFA tubing is not just a conduit for waste disposal; it is a critical component that safeguards the integrity of the CVD process and the environment. Its unique properties make it indispensable in maintaining the high standards required in semiconductor manufacturing.

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine Chemical Vapor Deposition Chamber System Equipment

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine