Introduction to Electric Rotary Kiln Pyrolysis Furnaces

Electric rotary kiln pyrolysis furnaces are pivotal in modern industrial processes, transforming waste into valuable resources and facilitating chemical reactions. This comprehensive guide delves into the intricacies of these furnaces, starting with an overview of their basic principles and significance across diverse industries. We will explore their design, operation, efficiency factors, and applications, providing a thorough understanding of how these advanced systems contribute to sustainable and efficient industrial practices. Join us as we uncover the mechanics, challenges, and innovations driving the evolution of electric rotary kiln pyrolysis technology.

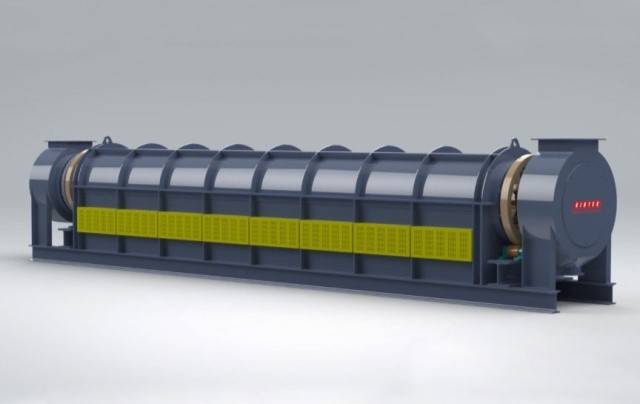

Design and Construction of Electric Rotary Kilns

The electric rotary kiln is a sophisticated piece of equipment essential for various high-temperature processes in industries such as cement, lime, and iron ore reduction. Its design and construction involve several critical components that ensure efficient operation and heat management. This section delves into the detailed description of these components, including the shell, refractory lining, support systems, and heat exchangers, highlighting their importance in the overall operation and efficiency of the kiln.

Kiln Shell

The kiln shell is the foundational structure of the rotary kiln, typically constructed from rolled mild steel plates, with thicknesses ranging from 15 to 30 mm. These plates are welded together to form a cylindrical structure that can extend up to 230 meters in length and 6 meters in diameter. The shell's primary function is to provide structural integrity and support the internal components. It is designed to withstand significant torsion and flexural stresses due to its own weight, the refractory lining, and the material being processed. The shell's design must also account for thermal expansion and contraction, which can be substantial, especially in longer kilns.

Refractory Lining

The refractory lining is a critical component that protects the steel shell from the extreme temperatures inside the kiln, which can exceed 1000°C. This lining is typically made from high-grade refractory materials such as magnesite, alumina, or silicon carbide, chosen based on the specific process requirements and the chemical resistance needed. The lining's thickness and composition are meticulously selected to ensure optimal heat retention and minimize heat loss. It also provides a stable surface for the material being processed, preventing direct contact with the metal shell, which could lead to damage or contamination.

Support Systems

The support system of a rotary kiln includes the tyres (riding rings) and rollers, which are essential for maintaining the kiln's alignment and facilitating its rotation. The tyres are mounted on the shell and ride on a series of rollers, which are strategically positioned to support the kiln's weight and allow for smooth rotation. These components are engineered to handle the significant loads and thermal stresses, ensuring that the kiln operates with minimal misalignment or deformation. The support system also includes the drive assembly, which consists of a gear ring and pinions, driven by a motor and gearbox. This assembly controls the rotational speed of the kiln, which is crucial for the uniformity of the processing.

Heat Exchangers

Heat exchangers are integral to the efficiency of the rotary kiln, facilitating the transfer of heat from the combustion gases to the material being processed. These can include preheaters, which preheat the feedstock before it enters the kiln, and clinker coolers, which cool the processed material after it exits the kiln. Advanced heat exchanger designs, such as those incorporating cyclone separators or grate coolers, enhance the heat recovery process, reducing energy consumption and improving overall efficiency. The selection and configuration of heat exchangers are tailored to the specific requirements of the process, ensuring optimal heat management and energy utilization.

In conclusion, the design and construction of an electric rotary kiln involve a complex interplay of various components, each playing a vital role in ensuring the kiln's efficient and reliable operation. From the robust steel shell and the insulating refractory lining to the precise support systems and advanced heat exchangers, every element is meticulously engineered to meet the stringent demands of high-temperature industrial processes. Understanding the function and importance of these components is essential for optimizing the performance and longevity of the rotary kiln.

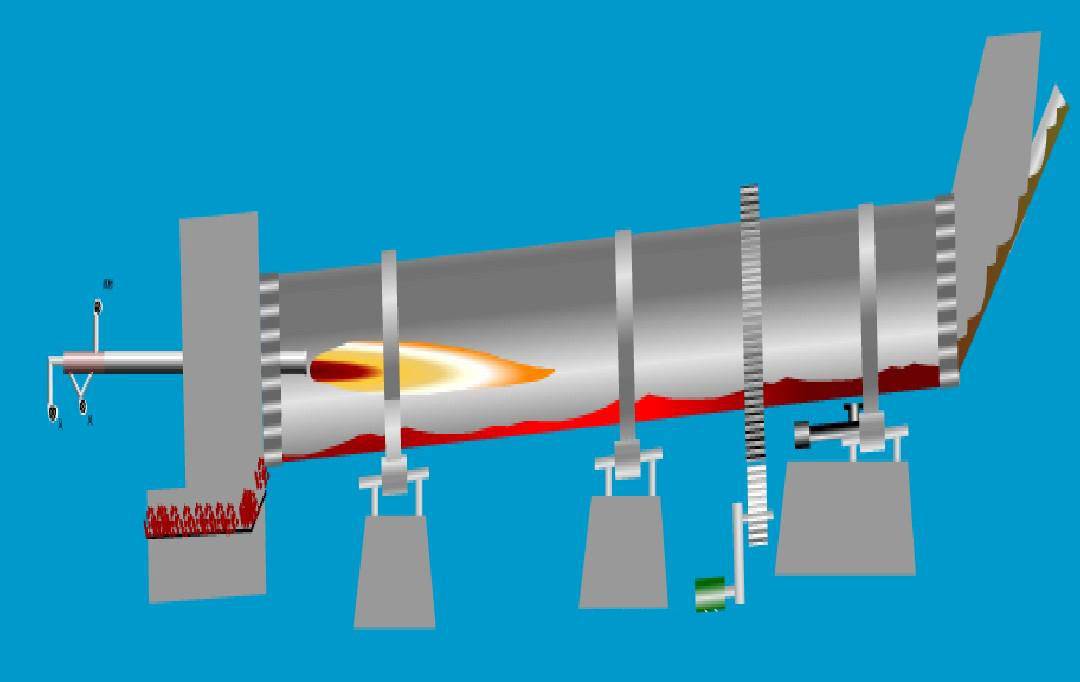

Principle of Operation and Process Flow

Electric rotary kilns operate on the principle of rotary drum technology, where materials are tumbled in a rotating drum that is heated either directly or indirectly to achieve the desired temperature and induce the intended chemical or physical reaction. The process involves several key components and mechanisms that ensure efficient and controlled pyrolysis.

Movement of Materials

The rotary kiln consists of a cylindrical shell, slightly inclined from the horizontal and rotated slowly around its longitudinal axis. Material to be processed is fed into the upper end of the cylinder. As the kiln rotates, the material gradually moves down towards the lower end, undergoing a certain amount of stirring and mixing due to the rotation and the slight inclination. This movement ensures uniform exposure of the material to the heat and facilitates the desired reaction.

Heat Supply Mechanisms

The heat supply in an electric rotary kiln can be either direct or indirect. In direct heating, hot gases are fed through the drum, directly contacting the material and heating it through convection and conduction. This method is efficient for processes requiring high heat transfer rates. In indirect heating, the material is heated through contact with the shell of the kiln, which is heated externally to maintain an inert environment. This method is suitable for processes where direct contact with hot gases could contaminate or alter the material.

Role of Rotation in the Pyrolysis Process

The rotation of the kiln plays a crucial role in the pyrolysis process. It ensures that the material is continuously mixed and moved along the kiln, preventing localized overheating and ensuring uniform heating. The rotation also helps in the evaporation of moisture and volatiles from the material, promoting the pyrolysis reaction. The speed of rotation is carefully controlled to optimize the retention time of the material within the kiln, ensuring that the material reaches the desired temperature and undergoes the necessary reaction before being discharged.

Process Flow

The process flow in an electric rotary kiln can be summarized as follows:

- Feeding: The material to be processed is fed into the upper end of the kiln using a feeding device.

- Heating: The material is heated through direct or indirect contact with hot gases or the kiln shell.

- Reaction: As the material moves down the kiln, it undergoes the desired chemical or physical reaction due to the controlled temperature and retention time.

- Discharging: The processed material is discharged from the lower end of the kiln using a discharging device.

- Control: The entire process is controlled by a control unit that monitors and adjusts parameters such as temperature, rotation speed, and retention time to ensure optimal performance.

Construction and Components

The basic components of an electric rotary kiln include:

- Shell: The cylindrical vessel that contains the material and rotates around its axis.

- Refractory Lining: A high-temperature resistant lining inside the shell that protects the metal shell from the high temperatures and chemical reactions.

- Support Tyres and Rollers: Components that support the weight of the kiln and facilitate its rotation.

- Drive Gear: The mechanism that drives the rotation of the kiln.

- Internal Heat Exchangers: Devices that enhance heat transfer within the kiln, improving efficiency.

Applications

Electric rotary kilns are widely used in various industries for processes such as:

- Cement Production: Calcination of limestone to produce cement clinker.

- Lime Production: Calcination of limestone to produce quicklime.

- Metallurgical Processes: Roasting of ores and production of iron ore pellets.

- Chemical Industry: Production of chemicals through thermal decomposition or synthesis.

In conclusion, electric rotary kilns are versatile and efficient devices for high-temperature processing of materials. Their principle of operation, involving the controlled movement, heating, and reaction of materials within a rotating drum, ensures precise and consistent results across a wide range of applications.

Efficiency and Performance Factors

The efficiency of electric rotary kiln pyrolysis furnaces is influenced by several key factors, including heat supply, speed of rotation, and material properties. Optimizing these factors can significantly enhance the performance of these furnaces, leading to improved outcomes in terms of product quality, energy consumption, and environmental impact.

Heat Supply

The method of heat supply is a critical determinant of the efficiency of electric rotary kiln pyrolysis furnaces. Electric resistance heating is commonly used due to its precise temperature control and rapid heating capabilities. High-speed electric heating can reduce the furnace's stopping and starting periods, thereby increasing operational efficiency. The use of light-weight polycrystalline ceramic fiber insulating liners further minimizes heat loss, making the process more energy-efficient and environmentally friendly.

Moreover, advanced control systems, such as touch screen controllers with intelligent PID thermal control technology, enable precise temperature management. These systems offer features like over-temperature and temperature sensor failure alarms, allowing for immediate corrective action. Additionally, the ability to save and switch between multiple heating programs facilitates easy adaptation to different production processes and formulas. Historical heating data can also be analyzed for continuous improvement and research purposes.

Speed of Rotation

The speed of rotation in a rotary kiln plays a significant role in heat distribution and material processing. The kiln is typically inclined at an angle and rotates at a slow pace, ensuring effective heat distribution to the substrate within the system. This slow rotation allows for uniform heating and optimal residence time for the material, which is crucial for achieving desired pyrolysis outcomes.

For instance, rotary-kiln pyrolysis reactors are particularly effective for slow pyrolysis operations, especially in the production of oil from biomass. The efficiency of these reactors is influenced by the speed of rotation, which must be carefully calibrated to match the specific requirements of the material being processed.

The properties of the material being pyrolyzed also have a profound impact on the efficiency of the furnace. Materials with high thermal conductivity and specific heat capacity can enhance heat transfer and overall efficiency. Additionally, the chemical composition and physical structure of the material can influence the pyrolysis process, affecting the yield and quality of the final product.

Nickel-based alloy furnace tubes are often used due to their high-temperature and corrosion resistance, ensuring minimal deformation even under continuous operation at temperatures up to 1100°C. This robustness is essential for maintaining the integrity and efficiency of the furnace over extended periods.

Customization and Environmental Considerations

Customization is another aspect that can enhance the efficiency of electric rotary kiln pyrolysis furnaces. For example, incorporating an air cooling mechanism can stabilize temperature control, preventing overshoots and ensuring consistent performance. The heater placement on the entire surface (360°) of the heating part, combined with a close distance between the heater and the retort, ensures even heat transmission, high heat efficiency, and minimal heat loss.

Environmental considerations are also paramount in the design and operation of these furnaces. By minimizing heat loss and using energy-efficient materials and technologies, electric rotary kiln pyrolysis furnaces can significantly reduce their environmental footprint. This not only aligns with sustainability goals but also enhances the overall efficiency and performance of the furnace.

In conclusion, optimizing factors such as heat supply, speed of rotation, and material properties is essential for maximizing the efficiency and performance of electric rotary kiln pyrolysis furnaces. By leveraging advanced technologies and customization options, these furnaces can achieve superior outcomes in terms of product quality, energy efficiency, and environmental sustainability.

Applications of Electric Rotary Kiln Pyrolysis Furnaces

Electric rotary kiln pyrolysis furnaces have become indispensable tools across a multitude of industries, revolutionizing processes in waste management, chemical production, and biofuel generation. These advanced furnaces utilize controlled thermal decomposition to transform raw materials into valuable products, making them a cornerstone in modern industrial practices.

Waste Processing

One of the most significant applications of electric rotary kiln pyrolysis furnaces is in the field of waste processing. These furnaces are employed in various waste-to-energy technologies, such as Plastics-to-Fuel (PTF) systems, which convert non-recyclable plastics into synthetic fuels. The pyrolysis process in rotary kilns allows for the treatment of a wide range of waste types, including municipal solid waste, hazardous waste, and medical waste. This not only aids in reducing landfill burdens but also contributes to the circular economy by converting waste into reusable resources.

Chemical Production

In the chemical industry, electric rotary kiln pyrolysis furnaces are used for the production of a variety of chemicals. They are particularly useful in the synthesis of methanol, activated carbon, and charcoal from biomass sources. The precise control over temperature and residence time in these furnaces ensures high-quality product output and efficient chemical reactions. Additionally, these furnaces are employed in the calcination of minerals like limestone and gypsum, which are crucial steps in the production of cement and plaster.

Biofuel Generation

The generation of biofuels is another area where electric rotary kiln pyrolysis furnaces demonstrate their versatility. These furnaces are used to convert biomass, such as wood chips, agricultural residues, and even sewage sludge, into biofuels like bio-oil, biochar, and syngas. The process of pyrolysis in rotary kilns allows for the efficient conversion of these materials into energy-rich products, which can be used as alternatives to fossil fuels, thereby reducing greenhouse gas emissions and promoting sustainability.

Case Studies and Real-World Applications

Several case studies highlight the effectiveness of electric rotary kiln pyrolysis furnaces in real-world applications. For instance, a leading chemical company utilizes these furnaces to produce high-grade activated carbon, which is essential for water purification and air filtration systems. Another example includes a waste management facility that employs rotary kilns to convert municipal solid waste into synthetic gas, which is then used to generate electricity, showcasing the integration of waste management with renewable energy production.

In conclusion, electric rotary kiln pyrolysis furnaces are pivotal in advancing sustainable practices across various industries. Their ability to efficiently convert waste materials into valuable resources, produce high-quality chemicals, and generate renewable biofuels underscores their significance in modern industrial processes. As technology continues to evolve, these furnaces will play an even more critical role in shaping a more sustainable and efficient future.

Maintenance and Safety Considerations

Maintaining electric rotary kiln pyrolysis furnaces is crucial for ensuring their longevity and safety. Proper maintenance not only extends the life of the equipment but also prevents accidents and ensures efficient operation. This section will discuss common issues, preventive measures, and safety protocols essential for the management of these high-temperature systems.

Common Issues in Electric Rotary Kilns

Electric rotary kilns, particularly those used in pyrolysis processes, can encounter several issues that affect their performance and safety. One common problem is refractory damage, which can occur due to thermal stress, chemical侵蚀, and mechanical wear. The rapid heating and cooling cycles can lead to significant expansion and contraction within the kiln, causing stress fractures in the refractory lining.

Another frequent issue is misalignment of the rotary kiln, which can result from improper installation or prolonged use without realignment. Misalignment can lead to uneven wear of the kiln shell and bearings, increasing the risk of mechanical failures and reducing energy efficiency.

Preventive Measures

To mitigate these issues, regular inspections and maintenance are essential. Inspections should include a thorough examination of the refractory lining, kiln alignment, and mechanical components such as bearings and gears. The frequency of inspections depends on the usage rate and the nature of the materials processed, but typically, an annual inspection is recommended for high-intensity operations.

Preventive maintenance practices include:

- Refractory Lining Maintenance: Regularly inspect and replace damaged refractory bricks. Implement a controlled heating and cooling schedule to minimize thermal stress.

- Alignment Checks: Conduct periodic alignment checks and adjust the kiln as necessary. This can prevent excessive wear and tear on mechanical components.

- Component Replacement: Replace worn-out bearings, seals, and other critical components to prevent breakdowns and ensure smooth operation.

Safety Protocols

Safety is paramount when operating electric rotary kilns. Operators must adhere to strict safety protocols to prevent accidents and injuries. Key safety measures include:

- Personal Protective Equipment (PPE): Operators should wear appropriate PPE, including heat-resistant gloves, aprons, and eye protection.

- Emergency Procedures: Establish clear emergency procedures for potential hazards such as fires, electrical shocks, and mechanical failures. Regularly train operators on these procedures.

- Safety Interlocks: Install safety interlocks on access doors, power switches, and other critical points to prevent unauthorized access and accidental operation.

- Temperature Monitoring: Use advanced temperature monitoring systems to continuously monitor the kiln's internal and external temperatures. Automatic shut-off mechanisms should be in place to prevent overheating.

Conclusion

In conclusion, the maintenance and safety of electric rotary kiln pyrolysis furnaces are critical for ensuring their efficient and safe operation. By addressing common issues through preventive measures and adhering to stringent safety protocols, operators can significantly enhance the longevity and reliability of these high-temperature systems. Regular maintenance, coupled with proper training and adherence to safety guidelines, will ensure that the rotary kiln operates at its optimal capacity, providing a safe and productive environment for all personnel involved.

Advancements in Electric Rotary Kiln Technology

Recent technological advancements in electric rotary kiln design and operation have significantly enhanced efficiency, reduced environmental impact, and improved user safety. Electric rotary kilns, such as those manufactured by KinTek, utilize advanced materials and control systems to achieve superior performance in various industrial applications, particularly in lime and cement production.

Material Innovations

The rotary tube of electric rotary kilns is now commonly fabricated from nickel-based alloys, capable of withstanding temperatures up to 1100°C. These alloys provide high resistance to corrosion and prevent deformation even under continuous operation at extreme temperatures. The use of silicon carbide (SiC) heating elements further enhances durability and ease of maintenance, ensuring a reliable and long-lasting heating source.

Energy Efficiency and Environmental Impact

One of the most significant advancements in electric rotary kiln technology is the integration of polycrystalline ceramic fiber insulating liners. These liners reduce heat loss and contribute to more energy-efficient operations, making the process both cost-effective and environmentally friendly. The adoption of high-speed electric heating methods also minimizes the downtime associated with furnace startups and shutdowns, further enhancing operational efficiency.

Advanced Control Systems

Modern electric rotary kilns feature sophisticated touch screen controllers equipped with intelligent PID thermal control technology. These systems offer over-temperature and sensor failure alarms, ensuring enhanced safety and reliability. Additionally, the ability to save and switch between multiple heating programs allows for seamless adaptation to different production processes, facilitating historical heating data analysis for continuous improvement.

Carbon Footprint Reduction

Electric rotary kilns offer a clean and efficient alternative to traditional fossil-fuel-based calcination processes. By replacing these emissions-heavy methods, industries can significantly reduce their carbon footprint. Moreover, the ability to capture CO2 during the process not only mitigates environmental impact but also opens up opportunities for CO2 reuse or sale, adding an additional layer of sustainability and economic benefit.

Performance and Reliability

Technological innovations such as hydraulic block wheel devices, high-precision metering piston pumps, speed control valves, and contact graphite block sealing devices have contributed to the stable performance and high yield of rotary kiln calcining systems. These advancements ensure low energy consumption and maintain the equipment's reliability and productivity.

In conclusion, the advancements in electric rotary kiln technology represent a significant leap forward in industrial processing. By leveraging these innovations, industries can achieve greater efficiency, enhanced safety, and a reduced environmental footprint, paving the way for a more sustainable and productive future.

Future Trends and Research Directions

The field of electric rotary kiln pyrolysis furnaces is poised for significant advancements, driven by the need for more sustainable and efficient industrial processes. As industries across the globe strive to reduce their carbon footprints and transition to cleaner energy sources, electric rotary kilns are emerging as a key technology in this transformation. Here, we explore potential future trends and areas of research that could shape the landscape of this field.

Enhanced Efficiency and Energy Conservation

One of the primary areas of focus for future research is the enhancement of energy efficiency in electric rotary kilns. Current developments aim to optimize the design and operation of these kilns to minimize energy consumption while maximizing output. For instance, advancements in insulation materials and heating technologies could significantly reduce thermal losses, thereby improving overall efficiency. Research into smart control systems that can dynamically adjust operating parameters based on real-time data is also expected to play a crucial role in achieving these efficiency gains.

Integration of CO2 Capture Technologies

The integration of carbon capture technologies with electric rotary kilns presents a promising avenue for reducing the environmental impact of industrial processes. By capturing CO2 emissions during the calcination process, industries can not only mitigate their contribution to climate change but also create new revenue streams by utilizing or selling captured CO2. Future research will likely focus on developing more efficient and cost-effective CO2 capture methods that can be seamlessly integrated into existing kiln systems.

Development of Advanced Materials

The production of advanced mineral products using electric rotary kilns is another area ripe for innovation. As industries seek materials with improved properties for various applications, such as roofing granules, adsorbents, and desiccants, the demand for specialized kiln processes will increase. Research into new materials and processing techniques will be essential to meet these demands. This includes exploring the use of alternative raw materials and developing new methods for modifying the physical and chemical properties of products.

Expansion into New Applications

Electric rotary kilns are also expected to expand into new and emerging applications, such as plastics-to-fuel (PTF) technology. The ability of these kilns to perform pyrolysis, converting plastic waste into fuel or petroleum products, offers a sustainable solution for managing plastic waste that cannot be processed through traditional methods. Future research will focus on optimizing these processes to handle a wider range of plastic waste types and improve the quality of the end products.

Technological Advancements and Automation

Technological advancements in electric rotary kilns are not limited to process improvements. The integration of advanced automation and control systems is expected to enhance the operational efficiency and safety of these kilns. For example, the use of hydraulic mechanisms, frequency control, and smart refractory materials can significantly improve the reliability and maintenance of kiln systems. Additionally, the development of predictive maintenance technologies using AI and machine learning could further reduce downtime and enhance the overall lifecycle of electric rotary kilns.

Environmental and Regulatory Considerations

As environmental regulations become more stringent, the design and operation of electric rotary kilns will need to adapt to meet these new standards. Research into cleaner combustion technologies, lower emission processes, and sustainable materials will be crucial. Additionally, the development of lifecycle assessment tools to evaluate the environmental impact of kiln operations will help industries make informed decisions about their processes.

Conclusion

The future of electric rotary kiln pyrolysis furnaces is bright, with numerous opportunities for innovation and improvement. By focusing on enhanced efficiency, CO2 capture, advanced materials, new applications, technological advancements, and environmental considerations, the industry can continue to drive progress towards a more sustainable and efficient future. These trends and research directions will not only benefit the industries directly involved in the production and use of electric rotary kilns but also contribute to broader environmental and economic goals.

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

Related Articles

- Rotary Furnaces: A Comprehensive Guide to Advanced Materials Processing

- Exploring the Benefits and Applications of Rotary Furnaces: A Comprehensive Guide

- Rotary Furnaces: Advanced Materials Processing and Applications

- Optimizing Industrial Processes: Rotary Kiln and Laboratory Furnace Solutions

- Exploring Rotary Tube Furnaces: A Comprehensive Guide