Understanding Tungsten Vacuum Furnaces

Explore the functionality and significance of tungsten vacuum furnaces in laboratory environments. Delve into the core components and operational mechanisms, including the role of tungsten crucibles and sample hot zones for various thermal processing applications.

Tungsten Furnaces - System Operation and Functionality

Tungsten vacuum furnaces, such as KinTek's range, feature advanced operational capabilities facilitated by a modernized touch screen Human Machine Interface (HMI) display. This interface empowers users to efficiently control all furnace functions, including pumping, gas handling, and venting, enhancing usability. The HMI display presents multiple screens showcasing operational status, interlock displays, and valve statuses.

The HMI interface facilitates the control of the automatic gas extraction and cooling program. This program is meticulously designed to eliminate residual oxygen from the furnace chamber, thereby prolonging the lifespan of the hot zone and mitigating the risk of oxidation.

What is a Vacuum Furnace?

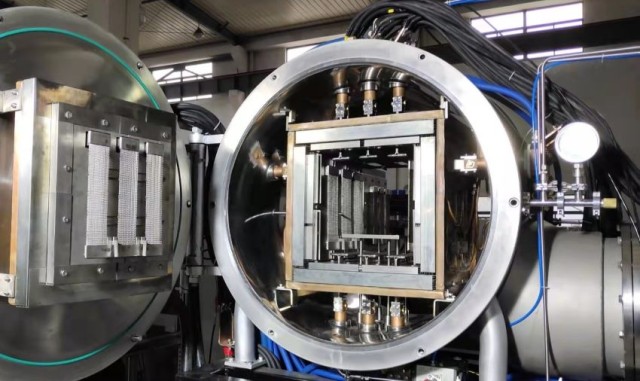

A vacuum furnace comprises three primary components: a high-speed diffusion pump, a vacuum chamber housing a high-temperature hot zone, and a control cabinet. The diffusion pump boasts an impressive pumping speed of 180,000 liters per minute, crucial for effectively managing high gas loads at elevated temperatures. Connected to the hot zone chamber via a large right-angle vacuum valve, the diffusion pump is complemented by a rotary vane vacuum pump. Monitoring of front line pressure is facilitated through a vacuum gauge tube. Notably, the system's base pressure in the hot zone at room temperature hovers around 1 x 10^-6 Torr.

The Hot Zone

The hot zone stands as the central component of the vacuum furnace. Comprised of molybdenum rod elements, the hot zone is resistively heated once the system achieves sufficient vacuum. Operating under vacuum conditions, temperatures within the hot zone can surpass 1300°C (2372°F). Control of the vacuum furnace is facilitated through a touch screen panel with Programmable Logic Controller (PLC), enabling operators to select and execute pre-programmed temperature/time profiles tailored to specific tasks. Additionally, pressure and temperature are continuously monitored and displayed at various points within the system. The control cabinet houses essential components such as transformers, contactors, and fuses.

Tungsten Furnaces - Service Requirements

All laboratory vacuum furnaces necessitate a three-phase power supply, chilled water supply and drain, argon gas for venting, process gas supply, and vent piping.

Tungsten Vacuum Furnaces Overview

Equipped with tungsten crucibles or flat sample hot zones, laboratory vacuum furnaces facilitate thermal processing, heat treating, annealing, and vacuum sintering in vacuum, nitrogen, or hydrogen atmospheres.

KinTek's vacuum furnaces offer a diverse range of tungsten hot zones catering to various applications. Operating at atmospheric pressure within an inert atmosphere, these furnaces boast an ultimate vacuum of 5 x 10^-2 mBar, ensuring optimal performance across a spectrum of laboratory processes.

KinTek's Advanced Tungsten Furnace Series

Discover the cutting-edge features and user-friendly interface offered by KinTek's range of tungsten vacuum furnaces. Learn how the modernized touch screen HMI display enhances control over furnace functions, from pumping and gas handling to venting, ensuring efficient and hassle-free operation.

Vacuum Furnaces

KinTek manufactures vacuum furnaces with operating pressures as low as 10-11 torr (mBar). These furnaces operate from room temperature to a maximum temperature of 3000 °C (5432 °F) in the tungsten hot zone and 2200 °C (3992 °F) in the graphite hot zone, with vacuum levels of roughly 10-2 torr/mBar.

The vacuum furnace comprises a hermetically sealed furnace chamber and an extraction system that removes air and gases from the chamber. Within the chamber, a heater heats and treats the product under vacuum conditions.

For various industries, KinTek offers the Advanced Tungsten Furnace Series, which includes a high temperature molywound Muffle Furnace capable of temperatures up to 1800°C in hydrogen, dissociated ammonia, forming gas, or any other reducing atmosphere. This furnace boasts features like preheat sections, binder removal sections, multiple zone controls, low or high dewpoint features, and turn-key automated pusher systems, making it a versatile problem solver suitable for a variety of processes such as:

- Refractory Metals

- Powder Metals

- Technical Ceramics

- Glass Formation

- Nuclear Fuel Disposal

- Sintering

- Metallizing

- Firing & Co-Firing

- Annealing

- Brazing

- Reducing

This reduction in furnace weight is particularly crucial in hand pouring operations. KinTek Furnaces are easier to maintain and cost less to repair than shell furnaces and aluminum frame furnaces due to their removable front and back inspection and access panels. They are constructed with durability in mind, ensuring a long furnace life. Additionally, they operate at frequencies from 3,000 to 10,000 hertz with maximum power utilization. KinTek Furnaces find ideal applications in prototype casting, small run casting, precious metal refining and casting, laboratory operations, and wherever relatively small amounts of molten metal are needed.

Tungsten Furnaces - System Operation and Functionality

KinTek's range of laboratory vacuum furnaces provides a user-friendly interface through a modernized touch screen HMI display. This interface allows for the control of all furnace functions, including pumping, gas handling, and venting, resulting in increased ease of use. Multiple screens display operation, interlock displays, and valve status.

The HMI facilitates control over the automatic gas extraction and cooling program. This program is designed to remove residual oxygen from the furnace chamber, thereby extending the life of the hot zone and preventing oxidation.

Key Features and Technical Specifications

Delve into the key features and technical specifications of tungsten vacuum furnaces, including temperature capabilities, base pressure, ramp rates, and process control options. Learn about the advantages of top-loading furnace chambers, water-cooled designs, and fully interlocked systems for enhanced safety and convenience.

Tungsten Vacuum Furnaces Overview

Laboratory vacuum furnaces equipped with tungsten crucibles or flat sample hot zones offer versatile thermal processing capabilities, including heat treating, annealing, and vacuum sintering. These furnaces operate within a controlled vacuum, nitrogen, or hydrogen atmosphere, providing precise conditions for various scientific applications.

Tungsten Furnaces - Key Features

Temperature Capabilities

- Temperatures reach up to 2600˚C, enabling high-temperature processes essential for materials research and development.

Base Pressure

- Maintains a base pressure below 5 x 10^(-2) mBar, ensuring optimal vacuum conditions for reliable performance.

Ramp Rates

- Rapid ramp rates of approximately 120˚C/min facilitate efficient heating and cooling cycles, reducing processing times.

Process Control

- Utilizes a laptop computer interface for comprehensive data logging and multi-step programmable thermal process control, offering flexibility and precision.

Furnace Chamber Design

- Features a top-loading furnace chamber for convenient sample placement and retrieval, enhancing workflow efficiency.

Cooling System

- Fully water-cooled design with a stainless steel chamber and lid ensures efficient heat dissipation, contributing to extended equipment lifespan.

Safety Measures

- Motorized lid with interlocking sensor and full protection interlocks ensure safe operation, making it suitable for university and inexperienced operators.

Automatic Gas Handling

- Implements an automatic pump purge program to remove residual oxygen from the chamber, preventing oxidation and preserving the integrity of the hot zone.

User Interface

- User-friendly HMI touch screen display provides intuitive control over furnace functions, including pumping, gas handling, and venting, enhancing usability.

Interlock System

- Fully interlocked system guarantees user and equipment safety, minimizing risks associated with operation.

Additional Features

- Supports processing under vacuum and atmospheric pressure, accommodating diverse experimental requirements.

- Enables heating of crucibles and wafer/flat samples, offering versatility for various research applications.

Tungsten Furnaces - Technical Advantages

Tungsten's unique properties make it an ideal material for hot zone construction in vacuum furnaces:

- High Melting Point: With a melting point of 3420ºC (6187ºF), tungsten withstands extreme temperatures encountered during thermal processing.

- Low Vapor Pressure: Exhibits low vapor pressure at high temperatures, minimizing contamination and ensuring purity of processed materials.

- High Strength: Demonstrates high hot strength, maintaining structural integrity under thermal stress.

- Low Thermal Expansion: Minimal thermal expansion reduces the risk of deformation or cracking during heating and cooling cycles.

- High Thermal Conductivity: Facilitates efficient heat transfer within the furnace chamber, promoting uniform temperature distribution.

- High Young’s Modulus: Offers excellent mechanical stability, essential for precise control over sample environments.

- Corrosion Resistance: Resists corrosion against acids and molten metals, ensuring durability in demanding experimental conditions.

- Recrystallization Temperature: Exhibits a recrystallization temperature between 1100º – 1400ºC (2012º – 2550ºF), maintaining structural integrity during prolonged use.

- Electrical Conductivity: Provides good electrical conductivity, enabling precise control over heating processes.

- Powder Metallurgy Production: Produced primarily using powder metallurgy methods, resulting in fine grain size and superior mechanical properties.

Tungsten vacuum furnaces offer researchers a reliable and versatile platform for advanced materials synthesis and characterization, with precise control over thermal processing parameters and enhanced safety features.

Applications of Tungsten in Vacuum Furnaces

Gain insights into the diverse applications of tungsten in vacuum furnace environments, particularly its role in ensuring structural integrity and stability at elevated temperatures. Explore real-world examples, such as roller rail assemblies, showcasing the versatility and reliability of tungsten in demanding thermal processing scenarios.

Laboratory vacuum furnaces are equipped with tungsten crucibles or flat sample hot zones for thermal processing, heat treating, annealing, and vacuum sintering in a vacuum, nitrogen, or hydrogen atmosphere. KinTek vacuum furnaces offer a range of tungsten hot zones for various applications. The tungsten furnace series boasts an ultimate vacuum of 5 x 10^-2 mBar while operating at atmospheric pressure in an inert atmosphere. This setup ensures optimal conditions for precision thermal processing.

Tungsten's Unique Properties

Shape Retention

Tungsten maintains its shape at high temperatures, making it ideal for welding electrodes. Additionally, it enables ultra-high-temperature diamond coating, crucial for applications requiring extreme heat resistance. Vapor deposition coating furnaces utilize tungsten wires to uniformly transmit high heat, facilitating diamond deposition.

High Density

The specific high density of tungsten finds applications in radiation shielding, collimators, sputtering target materials, and military inertial weapons systems. Its compact weight offers advantages over lead and gold, making it suitable for aerospace ballast and vibration dampening balance components.

Alloy Options and Machinability

Despite limited alloy options due to its unique melting point, tungsten alloys, such as heavy alloy, offer machinable forms. Heavy alloy, combining tungsten with nickel and copper or iron, can be pressed and sintered into shapes beyond pure tungsten wrought products, enhancing versatility in various applications.

Tungsten Powder Processing

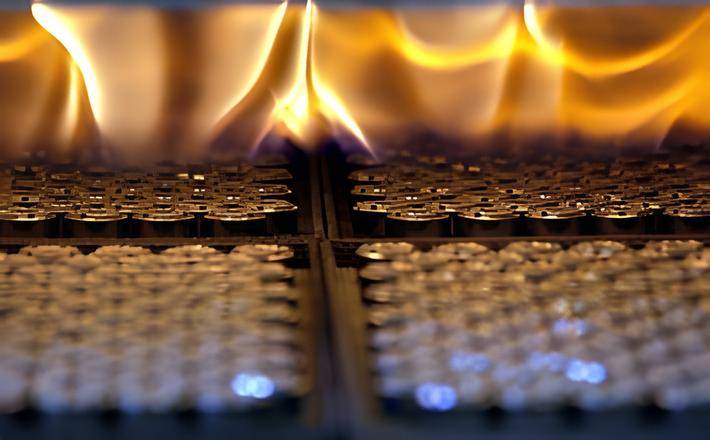

Tungsten powder is pressed into diverse shapes and dimensions, then sintered at temperatures ranging between 2000 – 2500ºC (3630 – 4530ºF) in hydrogen-filled furnaces. This process enhances the density and strength of the finished product, ensuring superior performance in demanding conditions.

Wide Range of Applications

Beyond vacuum furnaces, tungsten finds extensive use across various industries:

- Lighting: Tungsten is utilized in incandescent light bulbs for its heat resistance.

- Electrical: It serves in electrical contacts due to its conductivity and durability.

- Medical: Tungsten provides X-ray radiation shielding for medical equipment.

- Construction: Used in boring bars for its high strength and wear resistance.

Characteristics of Tungsten Grades

Tungsten is available in several alloy combinations, with the choice depending on operating temperature and product design. The grades' characteristics determine their suitability for specific applications, ensuring optimal performance and longevity.

Utilization in Vacuum Furnace Applications

Tungsten's exceptional properties make it indispensable in vacuum furnaces operating above 1315ºC (2400ºF). It ensures structural integrity at elevated temperatures and protects against material degradation. Notably, tungsten axles in roller rail assemblies exemplify its reliability in high-temperature environments, where conventional materials may fail.

In summary, tungsten's unique attributes make it a cornerstone of modern industrial and high-tech applications, particularly in vacuum furnace environments where reliability and performance are paramount. Its versatility and durability continue to drive innovation across diverse sectors, ensuring advancements in thermal processing and beyond.

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Arc Induction Melting Furnace

- Non Consumable Vacuum Arc Induction Melting Furnace

- Lab-Scale Vacuum Induction Melting Furnace

Related Articles

- How Vacuum Induction Melting Outperforms Traditional Methods in Advanced Alloy Production

- The Art of Absence: Why Advanced Materials Demand Vacuum Furnaces

- The Engineering of Nothingness: Why Vacuum Furnaces Define Material Integrity

- Exploring the Benefits of Using Tungsten for Furnace Heating

- How Vacuum Induction Melting Ensures Unmatched Reliability in Critical Industries