Introduction to Molybdenum Vacuum Furnaces

Molybdenum vacuum furnaces have emerged as a game-changer in industrial processes, revolutionizing operations in aerospace, automotive, and various other industries. These advanced furnaces, particularly the KIinTek Vacuum Furnaces, are engineered to achieve optimal vacuum levels, high temperatures, and rapid quenching rates. Their versatility in accommodating different load sizes, configurations, and hot zone materials such as Graphite, Molybdenum, and Hybrid is unparalleled. In this article, we will delve into the innovative design and functionality of these furnaces, exploring their diverse applications across industries, advanced technological features, and the crucial role of insulation for maintaining high-performance operations. Join us as we uncover the transformative potential of molybdenum vacuum furnaces in optimizing industrial processes.

Applications Across Industries

Delve into the diverse applications of vacuum furnaces across various industries, ranging from aerospace to automotive. Discover their indispensable role in enhancing performance and durability through specialized heat treatment processes.

Large Vacuum Heat Treatment Furnace Technology Applications

Large vacuum heat treatment furnaces play a crucial role in various industries, offering advantages such as minimal deformation, high-quality outcomes, operational flexibility, and environmental friendliness. These furnaces are not only essential for heat treating special alloys but also applicable to general engineering steel, particularly for tools, molds, and precision parts.

The longevity of vacuum heat treatment furnaces surpasses that of conventional ones significantly. For instance, after vacuum heat treatment, the lifespan of many tools and molds can increase by approximately 3-4 times. Moreover, these furnaces operate at higher temperatures, ensuring cleaner surfaces of workpieces, which accelerates chemical heat treatment processes such as carburizing, nitriding, chromatizing, and boriding, resulting in faster and superior outcomes.

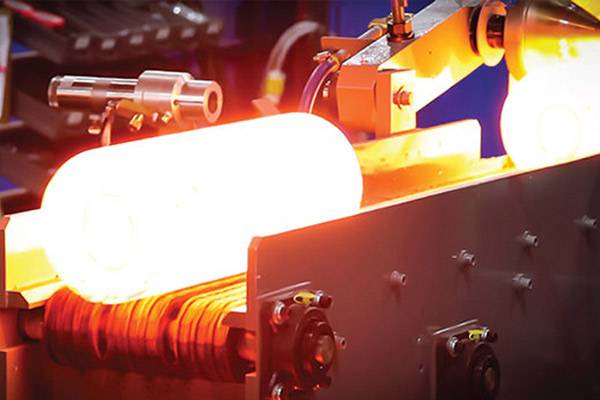

Vacuum Induction Melting Furnaces in Specialized Industries

In specialized industries like the nuclear sector, vacuum induction melting furnaces are indispensable for melting and casting low-enriched uranium metal into fuel rods. These furnaces also find extensive usage in aerospace for manufacturing aircraft, missile, and satellite components. Moreover, they contribute significantly to the production of metals like titanium and aluminum. Additionally, vacuum induction melting furnaces are pivotal in the power generation industry, especially for semiconductor and solar cell production, offering time and energy-saving advantages by melting metals at lower temperatures and pressures. They are particularly suitable for unique materials such as carbon fiber, requiring high temperatures and pressures for proper melting.

Heat Treatment of Steel and Alloys

Vacuum furnace heat treating offers oxidation-free hardening, stress relief, and cleaning of metal parts, critical for various industrial applications. Across International specializes in manufacturing customized vacuum furnace heat treating equipment tailored for precipitation hardening of metal alloys, essential in medical and industrial sectors.

These furnaces are also effective in removing residual and structural stresses from metal alloys. Precise temperature control during heating and cooling processes enables efficient stress removal from most metal materials.

Aerospace and Automotive Applications

In the aerospace industry, vacuum heat treatment plays a vital role in enhancing the performance and durability of critical components. Processes like solution annealing, aging, and stress relieving are employed to achieve desired mechanical properties in materials such as titanium alloys, nickel-based superalloys, and stainless steels.

Similarly, vacuum furnaces find extensive usage in the automotive sector for heat treating components like gears, bearings, springs, and engine parts. Processes like carburizing, nitriding, and quenching impart superior hardness, wear resistance, and fatigue strength to these components, ensuring enhanced performance and longevity.

By understanding the diverse applications of vacuum furnaces across industries, it becomes evident how they contribute to the advancement and efficiency of various manufacturing processes. From aerospace to automotive, these furnaces play a pivotal role in ensuring the reliability and quality of critical components, ultimately driving innovation and progress across sectors.

Insulation Techniques for Optimal Performance

In the realm of high-performance laboratory equipment, choosing the right insulation materials and fasteners is critical to ensuring efficient and reliable operations. Let's delve into the innovative solutions and techniques that elevate insulation effectiveness and durability.

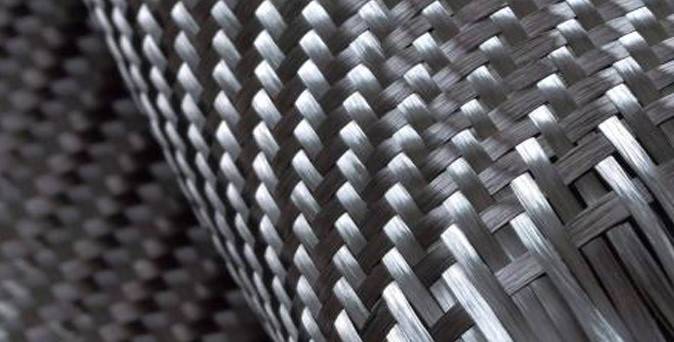

Carbon Fiber Reinforced Carbon (CFRC) Components

One standout advancement in insulation and fastening technology is the use of carbon fiber reinforced carbon (CFRC) components. These cutting-edge materials set new benchmarks for insulation performance. For instance, hard felt—a commonly used insulation material—can be shielded against gas erosion by applying a protective graphite coating. The ability to create and apply this coating on-site ensures optimal insulation integrity and longevity.

Efficient Fastening Solutions

Efficiency is paramount when it comes to fastening insulation in high-temperature furnaces. Traditional molybdenum screws, while standard, can pose challenges due to their susceptibility to brittleness and breakage after initial heating cycles. The resultant downtime and replacement costs associated with broken molybdenum fasteners underscore the need for more resilient alternatives.

Transition from Molybdenum to Graphite Elements

Historically, molybdenum elements dominated the vacuum furnace landscape. However, advances in graphite-based technologies have reshaped industry preferences. Early misconceptions regarding graphite's potential for material contamination have been dispelled by modern designs that offer superior durability and flexibility. Today, graphite heating elements, featuring lightweight and durable curved bands, have surpassed molybdenum in popularity for general heat-treating and brazing applications.

All-Metal Hot Zone Design

The evolution of all-metal hot zones represents a significant leap in furnace insulation engineering. These designs leverage materials like molybdenum and graphite to create multi-layered heat shield configurations. In standard applications with temperatures up to 1315°C (2400°F), the heat shield typically comprises molybdenum and stainless steel sheets, strategically layered to optimize thermal insulation. As temperatures escalate beyond 1650°C (3000°F), tantalum sheets can replace molybdenum for enhanced resilience.

Benefits of All-Metal Hot Zones

The all-metal hot zone design capitalizes on the insulating properties of gaps between sheet metal layers. This configuration effectively minimizes outward heat conduction, preserving internal temperature stability. Moreover, the reflective properties of inner molybdenum sheets redirect radiant heat inward, optimizing thermal efficiency.

Considerations and Challenges

While all-metal hot zones excel in high-vacuum and clean processing environments, operational care is essential due to molybdenum's susceptibility to embrittlement at elevated temperatures. The higher cost of molybdenum also influences the overall expense of all-metal hot zones compared to alternative insulation solutions.

In summary, advancements in insulation materials and fastening technologies are revolutionizing laboratory furnace performance. From innovative carbon-based components to sophisticated all-metal hot zone designs, these developments ensure optimal insulation integrity, longevity, and operational efficiency, setting new standards for high-performance laboratory equipment.

This article section highlights the evolving landscape of insulation techniques in laboratory equipment, emphasizing the transition towards more efficient and durable materials for enhanced operational reliability. The focus on carbon-based components and all-metal hot zones underscores the industry's commitment to pushing the boundaries of insulation technology.

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Arc Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

Related Articles

- Molybdenum Vacuum Furnace: High-Temperature Sintering and Heat Treatment

- Why Your Brazed Joints Are Inconsistent—And the Fix Isn't in the Furnace

- Your Vacuum Furnace Hits the Right Temperature, But Your Process Still Fails. Here’s Why.

- How Vacuum Induction Melting (VIM) Transforms High-Performance Alloy Production

- The Art of Absence: Why Advanced Materials Demand Vacuum Furnaces