There is a dangerous moment in every laboratory.

It happens right after the data is captured. The reaction is finished. The hypothesis is either confirmed or challenged. The adrenaline fades.

In this moment, the temptation is to simply walk away.

But for high-precision instruments like the five-port water bath electrolytic cell, this is actually the most critical phase. The experiment isn't over when the reaction stops; it is over when the equipment is neutralized.

Neglect here is not just a hygiene issue. It is a data integrity issue. A cell that "remembers" the last experiment through chemical residue will lie to you in the next one.

Here is the engineering philosophy of the shutdown—a ritual of closure that guarantees the truth of your future work.

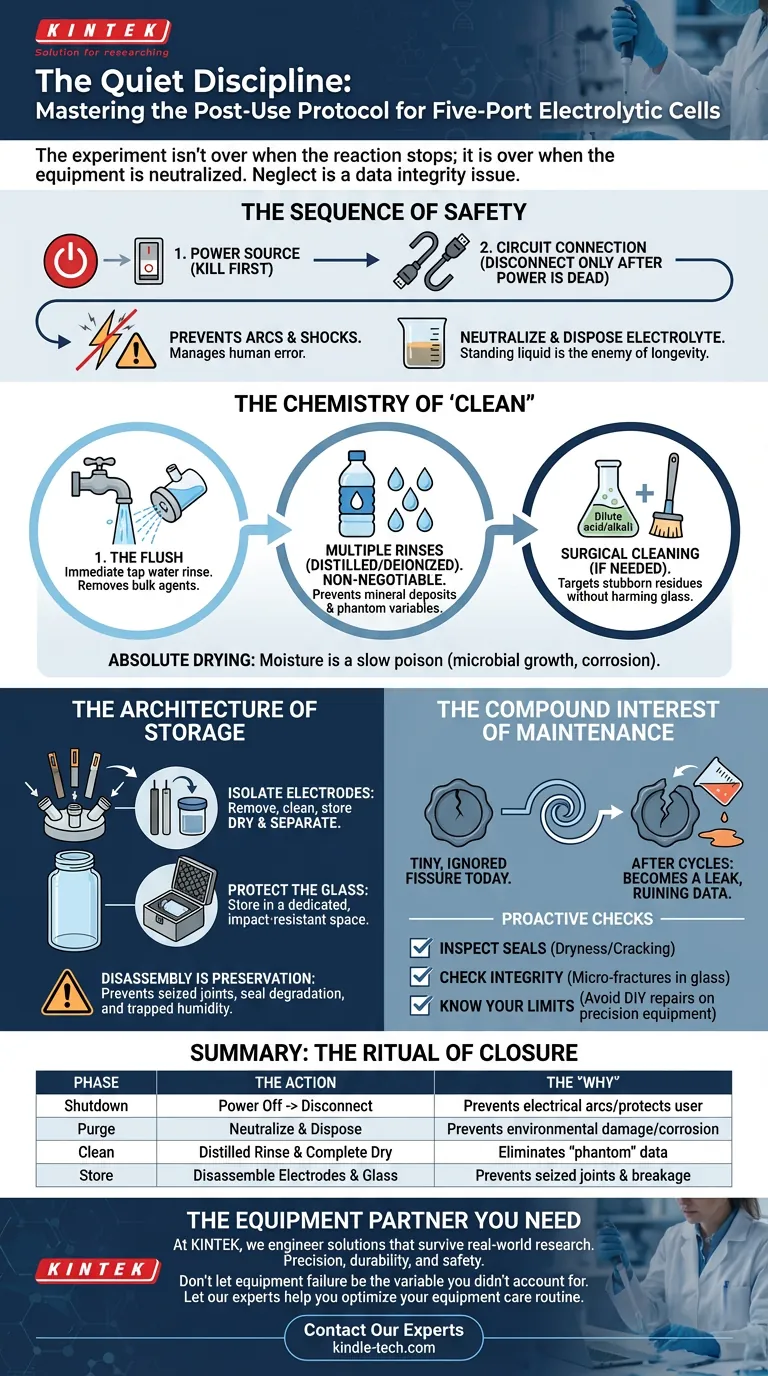

The Sequence of Safety

Great systems are designed to manage human error. In electrochemistry, the error is often assuming the machine is "dead" when it is merely "sleeping."

The shutdown protocol is not a suggestion. It is a strict chronological hierarchy designed to prevent arcs and shocks.

The Rule of Disconnection:

- Power Source: This must be killed first.

- Circuit Connection: Only after the power is dead do you touch the cables.

If you reverse this, you risk an electrical arc. It is a small spark, perhaps, but it signifies a breakdown in discipline that eventually leads to damaged electronics or user injury.

Once the energy is gone, you must manage the matter. The used electrolyte is now chemical waste. Whether it requires neutralization or specialized disposal, it must leave the vessel immediately. Standing liquid is the enemy of longevity.

The Chemistry of "Clean"

There is a difference between visually clean and chemically clean.

Your eye cannot see the microscopic salts clinging to the glass or the faint oxidation starting on an electrode. To the naked eye, the cell looks fine. To the next reaction, it looks like a contaminant.

We treat cleaning as a process of neutralization.

The Three-Stage Rinse

Water is the universal solvent, but only if used correctly.

- The Flush: Immediate rinsing with tap water to remove the bulk of the reactive agents.

- The Purification: Multiple rinses with distilled or deionized water. This is non-negotiable. Tap water leaves mineral deposits that act as phantom variables in future data.

- The Deep Clean: For stubborn residues, we introduce a solvent—a dilute acid or alkali compatible with the cell material. This is surgical cleaning, targeting specific byproducts without harming the glass.

Moisture is a slow poison. Even after rinsing, if the cell is stored wet, you invite microbial growth and corrosion. Drying must be absolute.

The Architecture of Storage

A five-port cell is a complex assembly of glass and metal. These materials age differently.

Glass is amorphous and brittle; it fears impact. Metal is crystalline and reactive; it fears oxidation.

Disassembly is Preservation Do not store the cell fully assembled. The interface between the electrode and the port is where seals degrade and corrosion hides.

- Isolate the Electrodes: Remove them. Clean them according to their specific metallurgy. Store them dry and separate.

- Protect the Glass: The cell body should be stored in a dedicated, impact-resistant space.

If you leave the system assembled, you are asking the seals to remain under compression and the metals to remain in contact with potential trapped humidity. It is a recipe for a seized joint or a leaked bath in two months.

The Compound Interest of Maintenance

Morgan Housel often writes that "compound interest is the most powerful force in the universe." This applies to equipment decay as well.

A tiny, ignored fissure in a seal seems irrelevant today. But after fifty thermal cycles in a water bath, that fissure becomes a leak. That leak compromises the temperature stability. That instability ruins a week-long experiment.

Proactive Checks:

- Inspect Seals: Look for dryness or cracking on port seals.

- Check Integrity: Glass does not bend; it cracks. Inspect for micro-fractures.

- Know Your Limits: If the water bath malfunctions or an electrode is deeply pitted, do not improvise a repair.

DIY repairs on precision equipment are rarely cost-effective. They usually trade a small repair bill today for a catastrophic equipment failure tomorrow.

Summary: The Ritual of Closure

The goal is to transform your equipment from a consumable item into a permanent asset.

| Phase | The Action | The "Why" |

|---|---|---|

| Shutdown | Power Off $\rightarrow$ Disconnect | Prevents electrical arcs and protects the user. |

| Purge | Neutralize & Dispose Electrolyte | Prevents environmental damage and plumbing corrosion. |

| Clean | Distilled Rinse & Complete Dry | Eliminates "phantom" data in future experiments. |

| Store | Disassemble Electrodes & Glass | Prevents seized joints and physical breakage. |

The Equipment Partner You Need

At KINTEK, we understand that a scientist is only as good as their tools. We don't just sell lab equipment; we engineer solutions that survive the rigors of real-world research.

From robust electrolytic cells to the consumables that keep them running, our products are designed with the engineer’s mindset: precision, durability, and safety.

Don't let equipment failure be the variable you didn't account for.

Let our experts help you optimize your equipment care routine. Contact Our Experts

Visual Guide

Related Products

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Electrolytic Electrochemical Cell with Five-Port

- Optical Water Bath Electrolytic Electrochemical Cell

- Multifunctional Electrolytic Electrochemical Cell Water Bath Single Layer Double Layer

- Electrolytic Electrochemical Cell Gas Diffusion Liquid Flow Reaction Cell

Related Articles

- The Invisible Architecture of Accuracy: Optimizing the Five-Port Electrolytic Cell

- The Silent Dialogue: Mastering Control in Electrolytic Cells

- Exploring the Multifunctional Electrolytic Cell Water Bath: Applications and Benefits

- The Art of Resistance: Why Your Electrolytic Cell Needs Breathing Room

- The Glass Heart of the Experiment: Precision Through Systematic Care