Introduction to Electrodes in Electrochemical Systems

Definition and Function of Electrodes

Electrodes are crucial components in electrochemical systems, serving as electronic conductors or semiconductors that interface with an electrolyte solution or a multiphase electrolyte system. Their primary function is to facilitate the transfer of electrical energy, either by inputting it into the system or outputting it from the system. This transfer of energy is essential for the occurrence of electrode reactions, which are the core processes in electrochemical cells.

In more detail, electrodes are where the chemical and electrical interactions converge. They provide the necessary pathways for electrons to move between the electrolyte and the external circuit, thereby enabling the conversion of electrical energy into chemical energy and vice versa. This dual role makes electrodes indispensable in applications ranging from batteries and fuel cells to sensors and industrial processes.

Moreover, the design and material selection of electrodes are critical to their performance. Different materials can significantly influence the efficiency, durability, and specificity of the electrode reactions. For instance, the choice of electrode material can affect the rate of electron transfer, the stability of the electrode surface, and the overall reaction kinetics. Thus, understanding the function and properties of electrodes is fundamental to optimizing the performance of electrochemical systems.

Three-Electrode System

The three-electrode system is a fundamental setup in electrochemical experiments, comprising the working electrode, the reference electrode, and the counter electrode. Each of these components plays a distinct role in facilitating the electrochemical process.

The working electrode is central to the experiment, as it is where the specific electrochemical reaction of interest occurs. This electrode interacts directly with the substances being studied, facilitating the transfer of electrons.

The reference electrode is crucial for maintaining a stable and known potential. It acts as a benchmark against which the potential of the working electrode is measured. Importantly, the reference electrode ensures that no current passes through it, maintaining its potential as a reliable standard.

The counter electrode, also known as the auxiliary electrode, complements the working electrode by completing the electrical circuit. Its primary function is to ensure that the current flow is balanced, preventing any interference with the reference electrode. Typically, the counter electrode has a larger surface area to minimize polarization effects, ensuring a stable current distribution.

This setup is particularly important in techniques like voltammetry, where precise measurement and control of electrode potentials are essential. By isolating the reference electrode from the current flow, the three-electrode system provides a robust framework for accurate electrochemical analysis.

Working Electrode

Role and Materials of Working Electrode

The working electrode (WE), often referred to as the research electrode, is the focal point where the electrochemical reaction of interest takes place. This electrode can be either solid or liquid, catering to a variety of experimental needs. The choice of material for the working electrode is crucial, as it directly influences the nature of the reactions and the accuracy of the measurements.

Common materials for working electrodes include:

- Glassy Carbon: Known for its stability and inertness, making it ideal for many electrochemical studies.

- Platinum: Highly conductive and resistant to corrosion, often used in physical-electrochemistry experiments.

- Gold: Offers excellent conductivity and is often used in sensitive measurements due to its low reactivity.

- Silver: Used in specialized applications where its unique electrochemical properties are beneficial.

- Lead: Employed in specific corrosion studies due to its susceptibility to corrosion.

- Conductive Glass: Used in applications requiring transparency, such as in electrochromic devices.

In corrosion experiments, the working electrode is typically the material undergoing corrosion, while in physical-electrochemistry experiments, it is often an inert material like gold, platinum, or carbon. These inert materials facilitate the transfer of current to other species without being affected by the current itself. The working electrode's surface must be well-prepared to ensure accurate and reproducible results. Polishing the electrode removes any surface imperfections and ensures that the geometric area closely matches the true surface area, thereby minimizing errors in current measurements.

| Material | Common Uses | Characteristics |

|---|---|---|

| Glassy Carbon | General electrochemical studies, stability tests | Stable, inert, good for many applications |

| Platinum | Physical-electrochemistry, high conductivity, corrosion resistance | Highly conductive, resistant to corrosion |

| Gold | Sensitive measurements, low reactivity | Excellent conductivity, low reactivity |

| Silver | Specialized applications, unique electrochemical properties | Used in specific scenarios where its properties are advantageous |

| Lead | Corrosion studies, susceptibility to corrosion | Employed in studies where corrosion behavior is the focus |

| Conductive Glass | Electrochromic devices, transparent applications | Used in applications requiring transparency and conductivity |

Ensuring the integrity of the working electrode's surface is paramount. Any changes in the electrode's surface, such as the formation of a coating or the presence of impurities, can significantly affect the current traces recorded during experiments. Therefore, it is essential to periodically verify the reproducibility of cyclic voltammograms (CVs) to confirm the electrode's integrity. If discrepancies are observed, it may indicate the need for re-polishing or replacement of the working electrode.

Experimental Setup

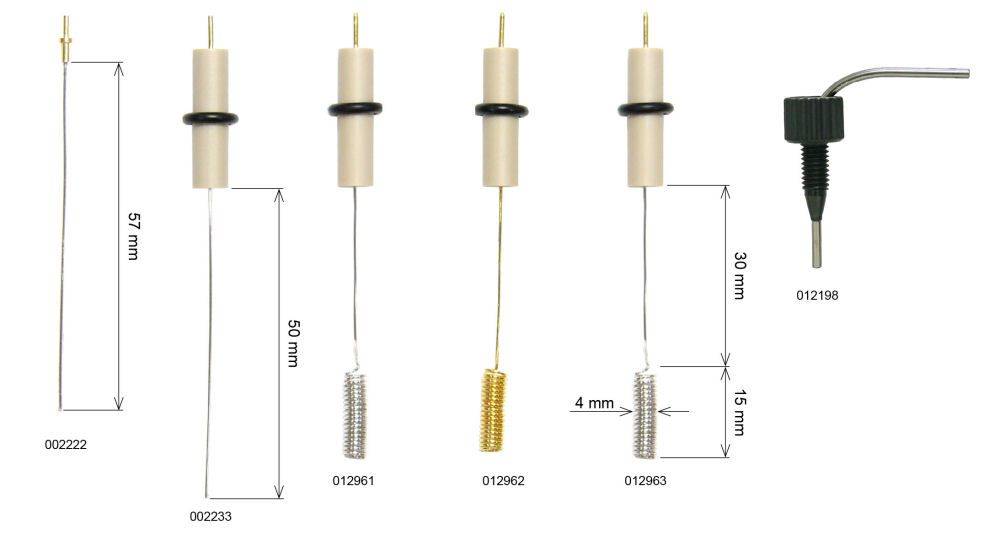

In the experimental setup of electrochemical systems, the precise positioning and stability of the working electrode (WE) are paramount. This is typically achieved through the use of specialized clamps designed to secure the working electrode firmly in place. These clamps are crucial for maintaining the electrode's position during experiments, ensuring consistent results and minimizing potential errors due to movement or instability.

The choice of clamp material and design can vary depending on the specific requirements of the experiment. For instance, some clamps are made from non-conductive materials to prevent any interference with the electrical measurements, while others may incorporate features like adjustable tension to accommodate different electrode sizes and shapes. Additionally, the clamps often include insulation to protect against electrical shorts and to ensure that only the intended electrode surfaces are in contact with the electrolyte.

Moreover, the clamps are often integrated with other components of the electrochemical cell, such as the reference and counter electrodes, to form a complete and functional system. This integration ensures that the entire setup operates harmoniously, facilitating accurate and reliable data collection.

In summary, the use of working electrode clamps is essential for the successful execution of electrochemical experiments, providing the necessary stability and precision to achieve accurate and reproducible results.

Counter Electrode

Function of Counter Electrode

The counter electrode (CE), often referred to as the auxiliary electrode, plays a crucial role in facilitating the smooth flow of current within an electrochemical circuit. This is essential for enabling the reaction of interest to take place at the working electrode (WE). The counter electrode acts as a complementary component to the working electrode, ensuring that electrons are efficiently transferred between the electrode and the solution.

In an electrochemical system, the current measured by the potentiostat is the flow of electrons from the working electrode to the counter electrode. This flow forms a complete circuit, allowing charge to be passed through the system. The counter electrode must be capable of rapid electron transfer to prevent any hindrance to the electron exchange occurring at the working electrode. For every electron transferred from the working electrode to a molecule in solution, an electron must be simultaneously removed from the solution by the counter electrode to maintain charge balance.

Given the necessity for swift electron transfer, counter electrodes are typically made from materials like platinum, which excel at facilitating electron exchange with species in solution. While a simple platinum wire is sufficient for many cyclic voltammetry (CV) experiments, high-current applications (> 1 mA) often require counter electrodes with larger surface areas, such as platinum gauze or metal foam, to ensure the appropriate amount of charge is handled efficiently.

In summary, the counter electrode is indispensable for maintaining the integrity and efficiency of the electrochemical process. Its role is not merely auxiliary but essential for the proper functioning of the entire electrochemical system.

Characteristics and Materials

The counter electrode (CE) plays a crucial role in maintaining a stable current flow, which is essential for the accurate measurement of the working electrode's potential. To achieve this, the counter electrode must exhibit minimal polarization effects, which can distort the true potential of the working electrode. This is typically achieved by ensuring the counter electrode has a significantly larger surface area compared to the working electrode.

The larger surface area helps to distribute the current more evenly, thereby reducing localized heating and minimizing the risk of polarization. Common materials used for counter electrodes include platinum and graphite rod electrodes. Platinum is particularly favored due to its excellent electrical conductivity and chemical stability, making it resistant to corrosion and oxidation. Graphite rods, on the other hand, offer a cost-effective alternative with good electrical conductivity and chemical inertness.

| Material | Advantages | Disadvantages |

|---|---|---|

| Platinum | High conductivity, chemical stability | Expensive |

| Graphite Rod | Cost-effective, good conductivity | Slower response time, potential for wear |

In summary, the choice of material for the counter electrode is critical to the overall performance of the electrochemical system. Both platinum and graphite rod electrodes offer distinct advantages and are widely used in various electrochemical applications.

Reference Electrode

Role of Reference Electrode

The reference electrode (RE) serves as a crucial component in electrochemical systems, providing a stable and well-known electrode potential. This stability is essential for accurately determining the electrode potential of the working electrode (WE) relative to the reference electrode. Unlike the working electrode, which undergoes the primary reaction under study, the reference electrode remains largely inert, with minimal current passing through it.

In an electrochemical cell, the reference electrode acts as a benchmark, allowing researchers to measure the potential of the working electrode in isolation. This is particularly important because the overall cell potential is the sum of the potentials from two half-reactions occurring at the working and reference electrodes. By standardizing the reference electrode with constant concentrations of the redox participants, the focus can be solely on the reaction at the working electrode.

The use of a reference electrode is not limited to simple half-cell measurements. It can also be integrated into more complex setups, such as combination electrodes, which combine a stable reference with a working cell in a single probe. While combination electrodes offer convenience, there are scenarios where separate reference and working electrodes are more practical, especially when different parts of the electrode are expected to have varying lifespans or when specific application requirements necessitate it.

When selecting a reference electrode, several factors must be considered to ensure compatibility and accuracy:

- Chemical Compatibility: The reference electrode should not interact chemically with the sample being measured.

- Stability: A stable potential is crucial for accurate measurements.

- Response Time: A fast response time ensures efficient analytical processes.

- Temperature Range: The electrode must be suitable for the application's temperature requirements. For instance, the saturated calomel electrode (SCE) is limited to 50°C.

- Material Suitability: The electrode's material should be resistant to degradation by the sample's chemical composition.

Given these considerations, the choice of reference electrode can significantly impact the accuracy and reliability of electrochemical measurements.

Common Types of Reference Electrodes

Reference electrodes are indispensable components in electrochemical systems, providing a stable and known potential against which the working electrode's potential can be measured. The most common types of reference electrodes include:

-

Ag/AgCl Electrode: This is one of the most widely used reference systems, known for its stability and reliability. It consists of a silver wire coated with silver chloride and is immersed in a chloride-containing electrolyte.

-

Saturated Calomel Electrode (SCE): Another popular choice, the SCE consists of mercury in contact with a paste of mercury(I) chloride (calomel) and a saturated solution of potassium chloride. Despite its stability, it contains mercury, making it unsuitable for certain applications due to environmental and safety concerns.

-

Mercuric Oxide Electrode: This electrode uses mercury oxide as its active material, typically immersed in a potassium hydroxide solution. It is known for its high stability and is often used in alkaline environments.

-

Mercurous Sulfate Electrode: This electrode is based on the reaction between mercury and mercurous sulfate, typically used in sulfate-rich solutions. It offers good stability and is particularly useful in specific industrial applications.

Additional Types of Reference Electrodes

In addition to the commonly used electrodes mentioned above, several other types are also employed depending on the specific requirements of the electrochemical system:

-

Standard Hydrogen Electrode (SHE): Although less practical due to its complexity and sensitivity to impurities, SHE serves as the universal reference with a standard potential of 0 V.

-

Copper-Copper Sulfate Electrode: This electrode is often used in soil science and environmental monitoring due to its stability and ease of use in aqueous environments.

-

Palladium-Hydrogen Electrode: Primarily used in non-aqueous solvents, this electrode provides a stable reference potential in organic media.

Considerations for Choosing Reference Electrodes

When selecting a reference electrode, it is crucial to consider factors such as compatibility with the sample, environmental impact, and disposal requirements. For instance, while calomel electrodes are very stable, their mercury content necessitates careful handling and disposal. Double junction electrodes, which allow customization of the lower chamber electrolyte, can be particularly useful in preventing interactions between the electrolyte and the sample, thereby ensuring accurate readings.

By understanding the characteristics and applications of these reference electrodes, researchers can make informed choices that enhance the accuracy and reliability of their electrochemical measurements.

Related Products

- Reference Electrode Calomel Silver Chloride Mercury Sulfate for Laboratory Use

- Lab Electrochemical Workstation Potentiostat for Laboratory Use

- Electrode Fixture for Electrochemical Experiments

- Platinum Auxiliary Electrode for Laboratory Use

- Copper Sulfate Reference Electrode for Laboratory Use

Related Articles

- Understanding Saturated Calomel Reference Electrodes: Composition, Uses, and Considerations

- Electrochemical Electrodes in Chemical Analysis

- Electrolytes and Electrochemical Electrodes

- How to Make Your Own Ag/AgCl Reference Electrode for Electrochemical Experiments

- Reference Electrodes: Calomel, Silver Chloride, and Mercury Sulfate - A Comprehensive Guide