The short answer is: it depends entirely on your application. Quartz heating elements are not universally "better," but they are superior for tasks requiring rapid, targeted, and high-intensity heat. Their effectiveness hinges on their unique method of heat transfer: direct infrared radiation.

The core distinction is not about which element is "better," but which method of heat transfer is right for your goal. Quartz heaters excel at radiant heating, which warms objects directly and instantly, while many other heaters excel at convective heating, which warms the surrounding air.

How Quartz Heaters Actually Work

To understand if a quartz heater is the right choice, you must first understand its fundamental principle of operation. Unlike conventional heaters, it doesn't primarily heat the air.

The Principle of Infrared Radiation

A quartz heater contains a resistance wire filament, typically tungsten or a nickel-chromium alloy, enclosed within a quartz tube. When electricity passes through the filament, it heats up to a very high temperature and emits powerful infrared (IR) energy.

This IR energy travels in straight lines, just like light. It passes through the air with minimal energy loss and only converts to heat when it strikes a solid object, such as a person, a piece of equipment, or a product on a conveyor belt.

Think of it like standing in the sun on a cold, crisp day. The air around you might be frigid, but you can feel the warmth of the sun's rays directly on your skin. This is the exact same principle.

The Role of the Quartz Tube

The quartz tube itself does not generate the heat. Its purpose is twofold: it provides a protective, inert atmosphere for the hot filament and, crucially, it is highly transparent to infrared radiation.

This transparency is key. It allows the vast majority of the IR energy to escape the element and travel to its target, making the heat transfer incredibly efficient.

Key Advantages of Quartz Heating

The radiant nature of quartz elements gives them several distinct advantages in the right context.

Unmatched Speed

Because they transfer energy via radiation at the speed of light, quartz heaters provide heat almost instantaneously. They often reach 90% of their full output in under 10 seconds. This is a stark contrast to convection heaters that must first warm up and then slowly circulate air.

High Energy Efficiency

For applications that involve heating a specific object or zone, quartz heaters are extremely efficient. Almost all the electrical energy is converted directly into IR energy that heats the target. Very little energy is wasted heating the vast volume of surrounding air.

Precise, Directional Heat

Just like a beam of light, infrared radiation can be focused and directed using reflectors. This allows you to apply intense heat exactly where it is needed, making it ideal for industrial processes like curing paint, drying materials, or thermoforming plastics.

Understanding the Trade-offs and Limitations

No technology is perfect for every scenario. The strengths of quartz heaters are also the source of their weaknesses in other applications.

Not Ideal for Space Heating

A quartz heater is generally a poor choice for raising the ambient temperature of an entire room. It creates "hot spots" where you feel intense warmth, but the moment you move out of its direct line-of-sight, you feel cold again. It does not produce a stable, uniform room temperature.

Sensitivity to Obstructions and Distance

Since the heat is delivered via line-of-sight radiation, any object that blocks the path will create a "heat shadow." The intensity of the heat also drops off significantly with distance from the element.

Fragility and Durability

The quartz tube is a form of glass, making it brittle and susceptible to breakage from physical impact or thermal shock (like being splashed with cold liquid while hot). In rugged industrial environments, more robust metal-sheathed elements are often a better choice.

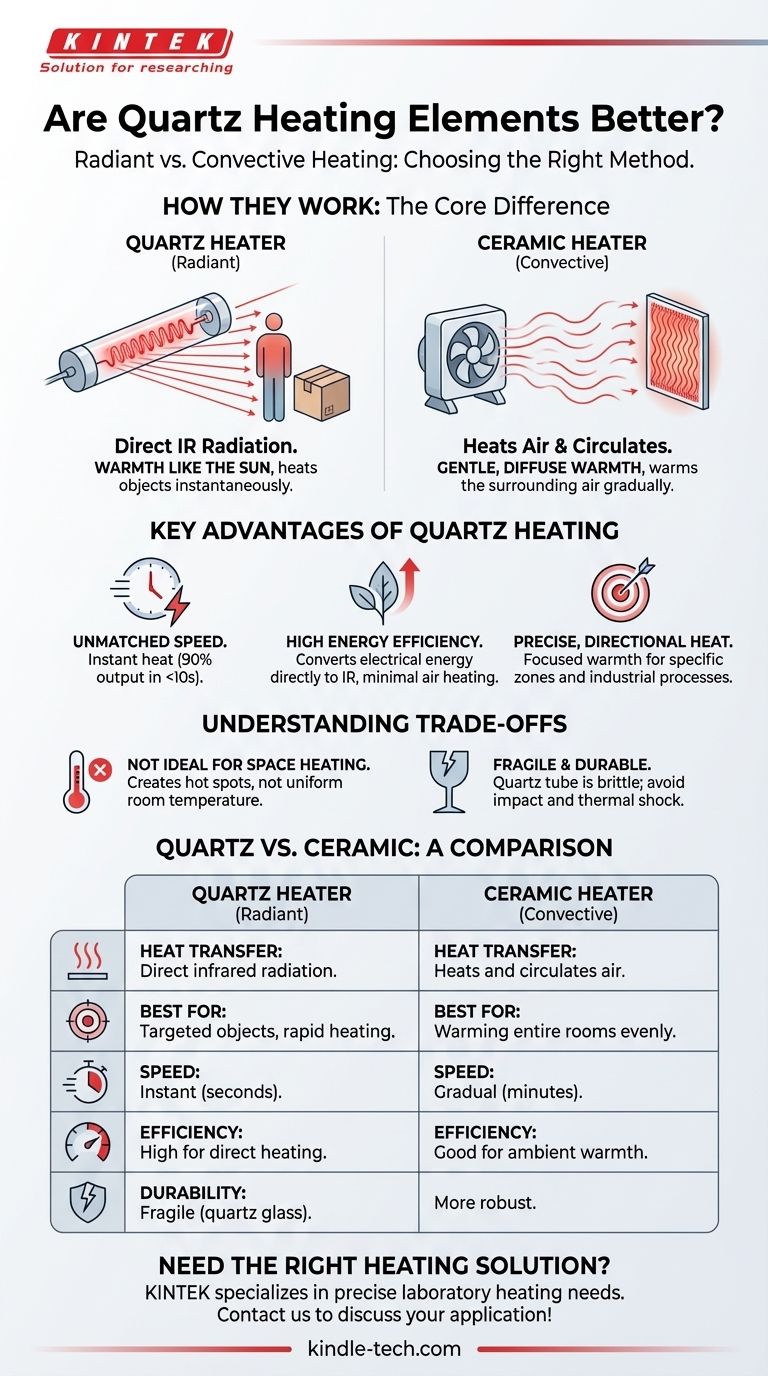

Quartz vs. Ceramic: The Most Common Comparison

Many users find themselves choosing between quartz and ceramic heaters. The difference is fundamental.

Heat Transfer Method

Quartz heaters are primarily radiant. They are designed to heat objects directly and quickly.

Ceramic heaters are primarily convective. A heating element warms a ceramic plate, and a fan blows air across the plate to heat the room. They are designed to heat the air.

Heat Character

The heat from a quartz element is intense and immediate. The heat from a ceramic heater is gentle and diffuse, creating a more even and comfortable ambient warmth over time.

Making the Right Choice for Your Application

Your decision should be guided by the specific heating task you need to accomplish.

- If your primary focus is rapid, targeted heating of a specific object or zone (e.g., industrial curing, outdoor patio heating, food warming): Quartz is almost always the superior choice due to its direct infrared output and instant response.

- If your primary focus is raising the stable, ambient temperature of an enclosed room (e.g., an office, living room, or bedroom): A ceramic or other convection-based heater is the correct tool for creating consistent, comfortable warmth.

- If your primary focus is durability in a high-traffic or rugged environment: A robust metal-sheathed or heavy-duty ceramic element will likely provide a longer service life than a more fragile quartz tube.

Ultimately, understanding the fundamental difference between radiant and convective heat empowers you to select the right technology for the job.

Summary Table:

| Feature | Quartz Heater (Radiant) | Ceramic Heater (Convective) |

|---|---|---|

| Heat Transfer | Direct infrared radiation | Heats and circulates air |

| Best For | Targeted objects, rapid heating | Warming entire rooms evenly |

| Speed | Instant (seconds) | Gradual (minutes) |

| Efficiency | High for direct heating | Good for ambient warmth |

| Durability | Fragile (quartz glass) | More robust |

Need the Right Heating Solution for Your Lab or Process?

KINTEK specializes in lab equipment and consumables, serving precise laboratory heating needs. Whether you require rapid infrared heating for industrial processes or reliable ambient warmth for your workspace, our experts can help you select the ideal equipment for maximum efficiency and performance.

Contact us today to discuss your specific application and get a tailored recommendation!

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Multi-zone Laboratory Tube Furnace

People Also Ask

- What is the temperature range of a MoSi2 heating element? Unlock 1900°C Performance for Your Lab

- What are the properties of molybdenum heating element? Choose the Right Type for Your Furnace Atmosphere

- What is the temperature range of molybdenum disilicide heating elements? Choose the Right Grade for Your High-Temp Needs

- Is molybdenum disulfide a heating element? Discover the best material for high-temperature applications.

- What is the thermal expansion coefficient of molybdenum disilicide? Understanding its role in high-temperature design