Yes, absolutely. Brazing is one of the most effective and widely used methods for joining two different (dissimilar) base metals. Unlike welding, brazing does not melt the base metals; instead, it uses a filler metal with a lower melting point that is drawn into the joint through capillary action, creating a strong metallurgical bond upon cooling.

The core principle that makes brazing ideal for dissimilar metals is that the base metals are only heated, never melted. A separate filler metal, compatible with both base materials, acts as the adhesive agent, eliminating many of the metallurgical problems that occur when trying to weld different metals together.

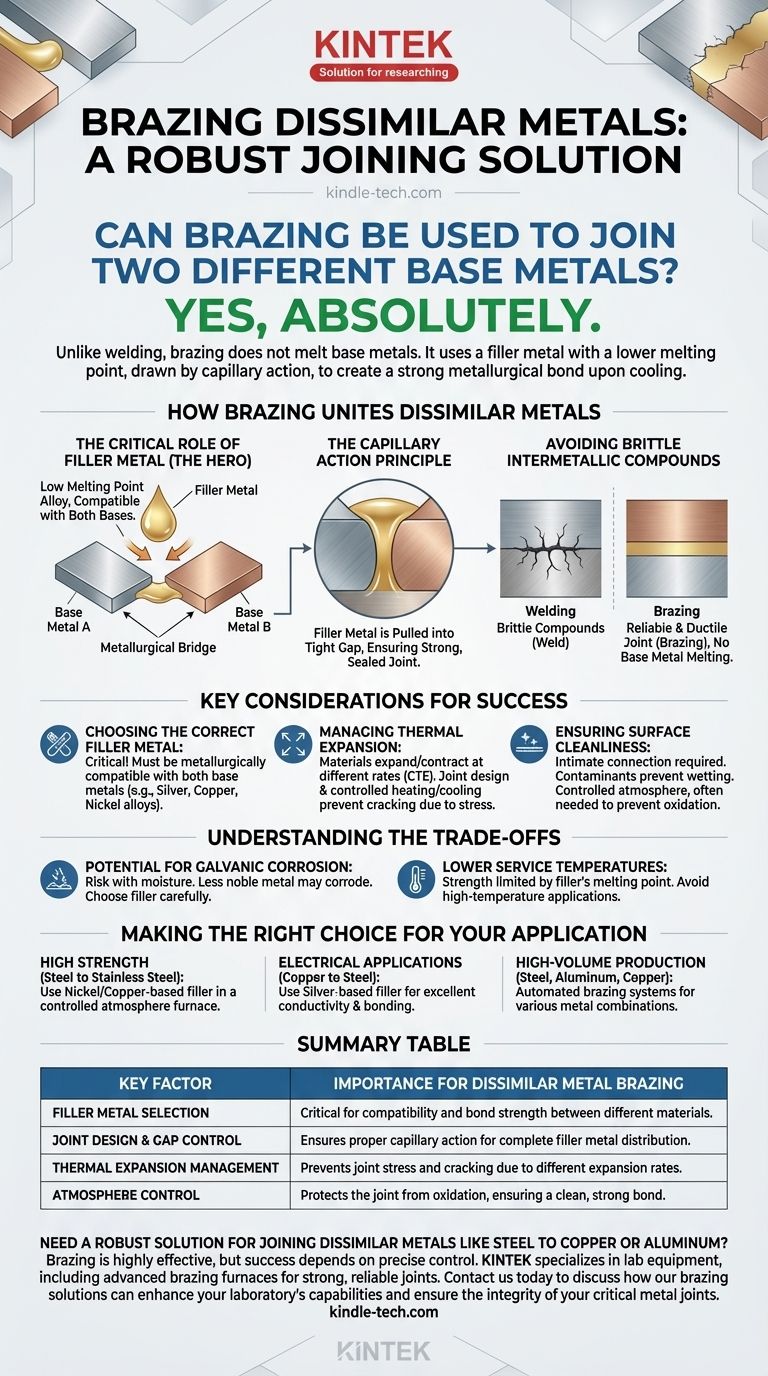

How Brazing Unites Dissimilar Metals

Understanding the process reveals why it is so well-suited for joining different materials. The success of the joint depends entirely on the interaction between the base metals and the filler metal, not between the base metals themselves.

The Critical Role of the Filler Metal

The filler metal is the hero of the brazing process. It is an alloy specifically chosen to have a melting point significantly lower than either of the two base metals being joined.

This filler must have the ability to "wet" and bond with both materials, effectively acting as a metallurgical bridge between them.

The Capillary Action Principle

For a strong joint, the gap between the two base metals is kept extremely tight. When the assembly is heated and the filler metal melts, it is automatically pulled into this gap by capillary action.

This ensures the entire joint surface is coated, resulting in a strong, sealed, and continuous connection.

Avoiding Brittle Intermetallic Compounds

A primary reason welding dissimilar metals is so difficult is that melting them together can create brittle intermetallic compounds at the joint. These compounds can severely compromise the strength and integrity of the weld.

Because brazing never melts the base metals, the formation of these problematic compounds is largely avoided, leading to a more reliable and ductile joint.

Key Considerations for Success

While brazing is highly effective, joining dissimilar metals requires careful control over several variables to ensure a reliable outcome.

Choosing the Correct Filler Metal

This is the most critical decision. The filler metal must be metallurgically compatible with both base metals. For example, filler metals like silver, copper, and nickel alloys are commonly used to join materials ranging from steel and stainless steel to copper and its alloys.

Managing Thermal Expansion

Different materials expand and contract at different rates when heated and cooled. This is known as the Coefficient of Thermal Expansion (CTE).

If the CTE difference between the two metals is significant, it can create immense stress on the joint as it cools, potentially causing it to crack. Joint design, heating, and cooling rates must be carefully controlled to manage this stress.

Ensuring Surface Cleanliness

Brazing relies on an intimate, molecule-to-molecule connection. Any contaminants like oil, grease, or oxides on the surface of the base metals will prevent the filler metal from wetting the surface and creating a strong bond.

This is why processes are often performed in a controlled atmosphere, such as in a vacuum or hydrogen brazing oven, to prevent oxidation at high temperatures.

Understanding the Trade-offs

Brazing is a powerful tool, but it's essential to recognize its limitations, particularly when joining different metals.

Potential for Galvanic Corrosion

Whenever two dissimilar metals are in contact in the presence of an electrolyte (like moisture), there is a risk of galvanic corrosion. The less noble metal can corrode at an accelerated rate.

The choice of filler metal can influence this, and the service environment of the final part must be a primary consideration in the design.

Lower Service Temperatures

The strength of a brazed joint is limited by the melting point of the filler metal. This means the final assembly cannot be used in applications where the service temperature would approach the filler's melting point.

Making the Right Choice for Your Application

Selecting the right process and materials depends entirely on the intended function of the final assembly.

- If your primary focus is high strength or joining stainless steel to steel: Consider using a nickel or copper-based filler metal in a controlled atmosphere furnace.

- If your primary focus is joining copper to steel for electrical applications: A silver-based filler alloy is often the ideal choice due to its excellent conductivity and bonding characteristics.

- If your primary focus is cost-effective, high-volume production: Automated brazing systems can be configured to handle a wide variety of metal combinations like steel, aluminum, and copper.

Brazing provides a robust and versatile solution for creating strong, clean joints between a wide array of different metals.

Summary Table:

| Key Factor | Importance for Dissimilar Metal Brazing |

|---|---|

| Filler Metal Selection | Critical for metallurgical compatibility and bond strength between different materials. |

| Joint Design & Gap Control | Ensures proper capillary action for complete filler metal distribution. |

| Thermal Expansion Management | Prevents joint stress and cracking due to different expansion rates. |

| Atmosphere Control | Protects the joint from oxidation, ensuring a clean, strong bond. |

Need a robust solution for joining dissimilar metals like steel to copper or aluminum?

Brazing is a highly effective method, but its success depends on precise control of temperature, atmosphere, and filler metal selection. KINTEK specializes in lab equipment and consumables, including advanced brazing furnaces designed for creating strong, reliable joints between a wide array of dissimilar metals.

Our expertise can help you achieve consistent, high-quality results for your specific metal combinations and application requirements.

Contact us today to discuss how our brazing solutions can enhance your laboratory's capabilities and ensure the integrity of your critical metal joints.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- How is the greatest joint strength obtained in brazing? Master the 3 Keys to Superior Metallurgical Bonds

- What metals can be joined by brazing? Discover the Versatility of Modern Brazing Techniques

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy

- What is the most important factor influencing the strength of the brazed joint? Master Joint Clearance for Maximum Strength