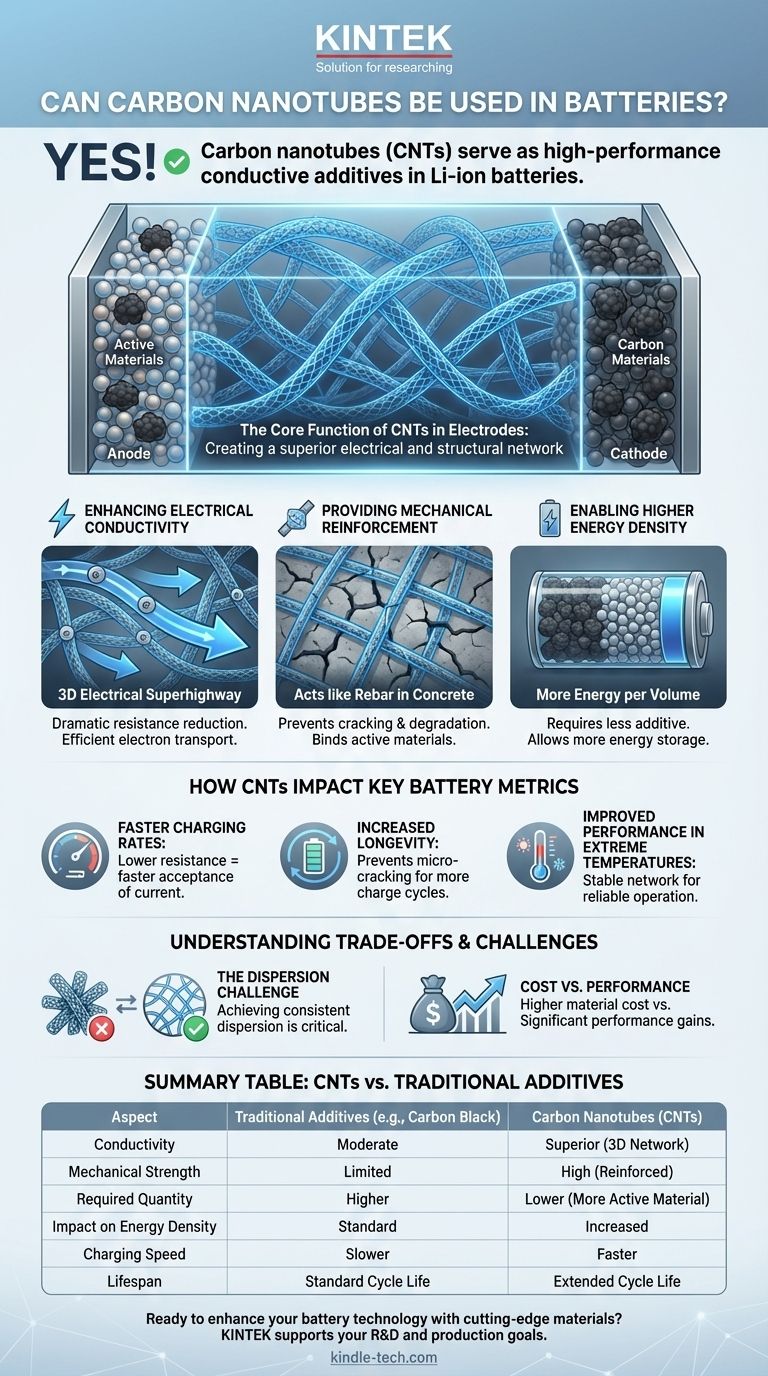

Yes, carbon nanotubes are actively and increasingly used in batteries, primarily serving as a high-performance conductive additive in the electrodes of lithium-ion batteries. By integrating a very small percentage of carbon nanotubes (CNTs) into the cathode or anode, manufacturers can dramatically improve key performance metrics like energy density, charging speed, and overall lifespan.

The core function of carbon nanotubes in a battery is not to act as the primary energy storage material, but to create a superior electrical and structural network within the electrode, unlocking the full potential of the active materials.

The Core Function of CNTs in Electrodes

To understand the value of CNTs, you must first understand a core limitation of battery electrodes. The active materials that store lithium ions, such as lithium cobalt oxide, often have poor electrical conductivity on their own.

Enhancing Electrical Conductivity

CNTs form a highly conductive, three-dimensional network throughout the electrode material. Think of it as a microscopic electrical superhighway.

This network creates a far more efficient pathway for electrons to travel between the active material and the current collector, dramatically lowering internal resistance.

Providing Mechanical Reinforcement

The long, thin, and incredibly strong structure of CNTs acts like rebar in concrete. They mechanically bind the active material particles together.

This reinforcement prevents the electrode from cracking and degrading during the physical expansion and contraction that occurs during charging and discharging, which is a primary cause of battery capacity fade over time.

Enabling Higher Energy Density

Because CNTs are so much more effective at providing conductivity and strength than traditional additives like carbon black, they are needed in much smaller quantities.

This allows engineers to pack more energy-storing active material into the same space, directly increasing the battery's energy density (the amount of energy stored per unit of volume or mass).

How CNTs Impact Key Battery Metrics

The superior electrical and mechanical properties provided by carbon nanotubes translate directly into tangible improvements in battery performance that users can experience.

Faster Charging Rates

Lower internal resistance means the battery can accept electrical current more efficiently and with less heat generation. This allows for significantly faster charging times without causing damage or accelerated degradation to the battery cell.

Increased Longevity and Cycle Life

By preventing the micro-cracking and physical breakdown of the electrode structure, CNTs help the battery retain its original capacity for many more charge-discharge cycles. This extends the useful lifespan of the battery, whether it's in an electric vehicle or a smartphone.

Improved Performance in Extreme Temperatures

The robust conductive network created by CNTs is more stable across a wider temperature range. This helps the battery perform more reliably in both hot and cold conditions, where the performance of batteries using traditional additives can suffer significantly.

Understanding the Trade-offs and Challenges

While the benefits are clear, successfully integrating CNTs into battery manufacturing is a non-trivial engineering challenge that requires careful consideration.

The Dispersion Challenge

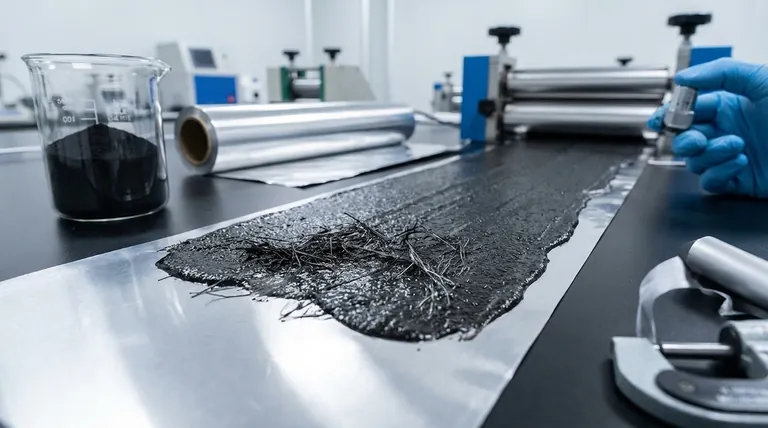

By their nature, CNTs have a strong tendency to clump together, a process known as agglomeration. If they are not properly dispersed into a uniform network, they can actually create defects and hinder performance rather than improve it.

Achieving consistent, high-quality dispersion is the single most critical factor in unlocking the benefits of CNTs and is a major focus of manufacturing process development.

Cost vs. Performance

High-purity carbon nanotubes are more expensive than the traditional carbon black additives they replace. While the cost has decreased significantly, it remains a factor for cost-sensitive applications.

However, for high-performance applications like electric vehicles, the gains in energy density and charging speed often justify the added material cost.

Formulation and Process Integration

Switching to CNTs is not a simple drop-in replacement. It requires reformulating the entire electrode slurry and may involve adjusting coating, drying, and calendering processes to work with the unique properties of the nanotubes.

Making the Right Choice for Your Goal

The decision to use CNTs depends entirely on the performance and cost targets of the final application.

- If your primary focus is maximum performance: For applications like electric vehicles, high-end electronics, or energy storage systems, CNTs are a key enabling technology for achieving higher energy density, faster charging, and longer life.

- If your primary focus is lowest possible cost: For standard, low-drain devices where performance is secondary to unit cost, traditional carbon black additives may still be a viable choice.

- If your primary focus is manufacturing: Your engineering efforts must be centered on developing and controlling a robust dispersion process to ensure the theoretical benefits of CNTs are realized in production.

Ultimately, carbon nanotubes represent a powerful tool for pushing the boundaries of what is possible with current lithium-ion chemistry.

Summary Table:

| Aspect | Traditional Additives (e.g., Carbon Black) | Carbon Nanotubes (CNTs) |

|---|---|---|

| Conductivity | Moderate | Superior (3D network) |

| Mechanical Strength | Limited | High (reinforces electrode) |

| Required Quantity | Higher | Lower (enables more active material) |

| Impact on Energy Density | Standard | Increased |

| Charging Speed | Slower | Faster (lower resistance) |

| Lifespan | Standard cycle life | Extended cycle life |

Ready to enhance your battery technology with cutting-edge materials?

KINTEK specializes in providing high-performance lab equipment and consumables, including materials like carbon nanotubes, to support your R&D and production needs. Whether you're developing next-generation batteries or optimizing electrode formulations, our expertise can help you achieve superior performance and efficiency.

Contact us today to discuss how we can support your battery innovation goals!

Visual Guide

Related Products

- Aluminum Foil Current Collector for Lithium Battery

- High Purity Zinc Foil for Battery Lab Applications

- Battery Lab Equipment 304 Stainless Steel Strip Foil 20um Thick for Battery Test

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Button Battery Disassembly and Sealing Mold for Lab Use

People Also Ask

- What are the requirements for CuBi2O4 composite coatings vs. copper? Optimize Deposition with Precision Control

- What are the material properties of carbon paper? Unlocking High Conductivity & Porosity for Your Lab

- What is the primary function of a vacuum drying oven in the pretreatment of PEO electrolytes? Achieve Battery Stability

- Why use a vacuum drying oven for Li4Ti5O12 electrode sheets? Ensure Battery Stability and Longevity

- Why are molten salt electrolytes important for Lithium-Air batteries? High-Performance Consumables for Energy Storage

- Why are customized pressure test cells necessary for ASSB testing? Master Solid-State Battery Performance

- What is the function of a magnetic stirring heating device in silver nanoparticle synthesis? Precision Control for Battery Collectors

- What are the advantages of using high-grade stainless steel for experimental Zinc-Air battery cells? Ensure Precision.