In nearly all cases, no. Annealing is a heat treatment process specifically designed to do the opposite: it softens a material, reduces its hardness, and increases its ductility. This process makes the material easier to work with for subsequent manufacturing steps.

The purpose of annealing is not to strengthen a material, but to make it more workable and stable. By softening the metal and relieving internal stresses, annealing prepares it for processes like shaping, machining, or welding where a harder, more brittle material would fail.

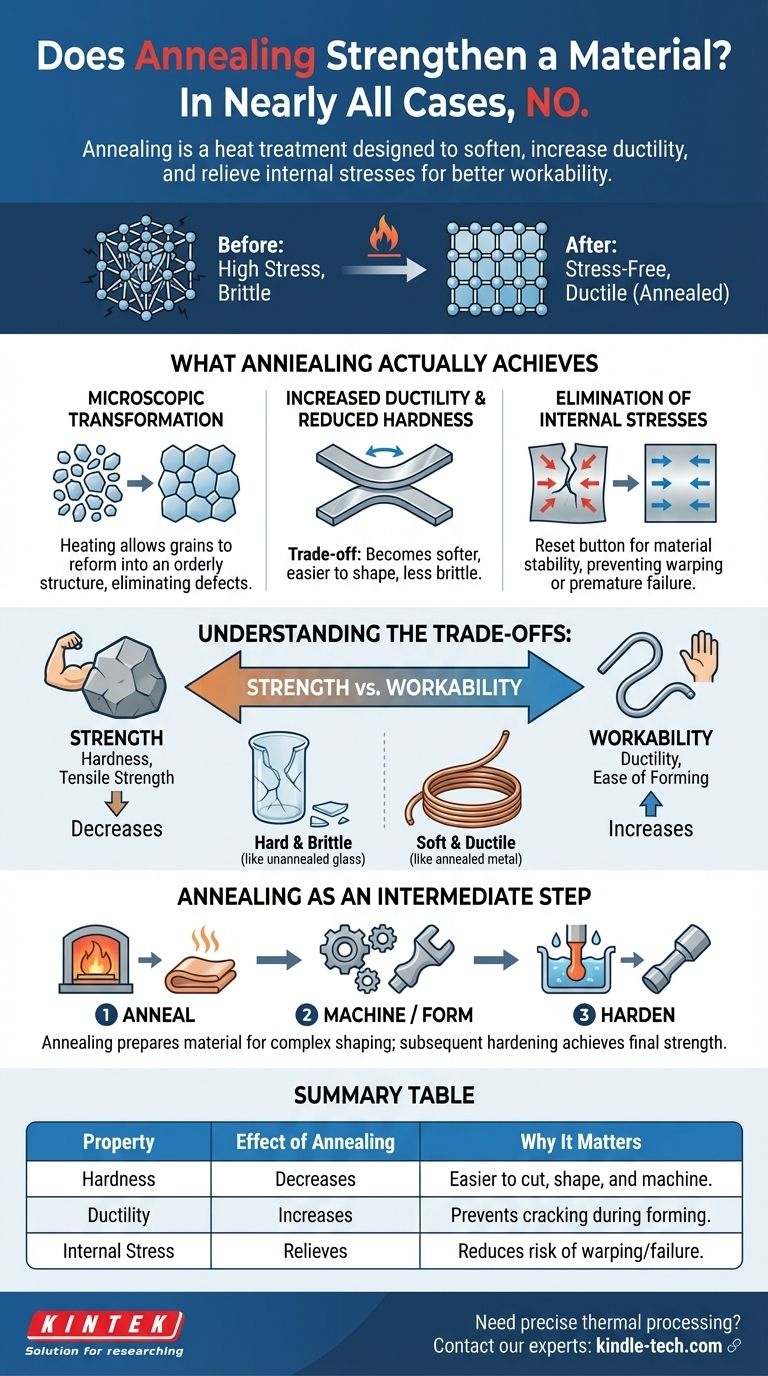

What Annealing Actually Achieves

Annealing is a precise process of heating a material above its recrystallization temperature, holding it there, and then cooling it very slowly. This controlled cycle fundamentally changes the material's internal structure for the better.

The Microscopic Transformation

At a microscopic level, materials are made of crystal structures called grains. Processes like cold working or welding deform and strain these grains, creating a chaotic, high-stress internal structure.

Heating the material during annealing provides the energy for these grains to reform. The slow cooling process allows them to grow in a more uniform and orderly way, eliminating the defects and stresses locked inside.

Increased Ductility and Reduced Hardness

The most noticeable result of annealing is a trade-off between hardness and ductility.

Ductility is a material's ability to be stretched, bent, or shaped without breaking. A more uniform grain structure allows the crystals to slip past one another more easily, making the material significantly more ductile and less brittle.

This directly results in a reduction in hardness. The material becomes softer and easier to cut, press, or machine.

Elimination of Internal Stresses

Internal stresses are locked-in forces within a material, often left over from manufacturing processes. These stresses are invisible but dangerous, as they can lead to unexpected warping, cracking, or premature failure over time.

Annealing provides a "reset" for the material. The heat allows the atoms to rearrange into a lower-energy, stress-free state, vastly improving the material's stability and reliability.

Understanding the Trade-offs

The core confusion around annealing comes from not recognizing the fundamental trade-off between strength and workability. In materials science, you rarely get something for nothing.

Defining "Strength" vs. "Workability"

While we often use "strength" as a single term, it can refer to different properties like tensile strength (resisting being pulled apart) or hardness (resisting indentation). Annealing generally reduces both of these.

Workability, on the other hand, is the ease with which a material can be formed into a desired shape. A hard, strong material is often brittle and has poor workability—it will crack before it bends.

Why You Would Want a Softer Material

Imagine trying to bend a piece of glass versus a piece of soft copper wire. The glass (hard and brittle) shatters, while the copper (soft and ductile) bends easily.

Annealing makes steel and other metals behave more like that copper wire. This is essential for manufacturing complex parts, drawing wire, stamping car body panels, or machining precise components.

Annealing as an Intermediate Step

Crucially, annealing is often not the final step. A typical manufacturing process might look like this:

- Anneal the raw material to make it soft and workable.

- Machine or form the soft material into its final shape.

- Harden the finished part using a different heat treatment (like quenching and tempering) to achieve the final desired strength.

How to Apply This to Your Goal

Choosing the right heat treatment depends entirely on your objective for the material at that specific stage of production.

- If your primary focus is manufacturability: Annealing is the correct process to make a material easier to shape, machine, or form without failure.

- If your primary focus is stability: Use annealing after processes like welding or heavy machining to relieve internal stresses and prevent future distortion or cracking.

- If your primary focus is final strength and hardness: Annealing is the preparatory step, not the solution. You will need a subsequent hardening process to achieve these properties.

Understanding annealing is about recognizing that true material control lies in preparing it for its purpose, not just maximizing a single property.

Summary Table:

| Property | Effect of Annealing | Why It Matters |

|---|---|---|

| Hardness | Decreases | Makes material easier to cut, shape, and machine. |

| Ductility | Increases | Prevents cracking during bending or forming operations. |

| Internal Stress | Relieves | Reduces risk of warping or failure in the final product. |

Need precise thermal processing for your lab work?

Annealing is just one critical step in material preparation. KINTEK specializes in the lab equipment and consumables needed for exacting heat treatment processes, helping you achieve optimal material properties for research and development.

Contact our experts today to discuss how our solutions can enhance your laboratory's capabilities and ensure your materials perform as required.

Visual Guide

Related Products

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 1200℃ Muffle Furnace Oven for Laboratory

- Multi-zone Laboratory Tube Furnace

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

People Also Ask

- What is a sputtering machine? A Guide to High-Quality Thin Film Deposition

- What temperature does titanium vaporize at? Unlocking Its Extreme Heat Resistance for Aerospace

- What is the purpose of using vacuum-sealed glass tubes for Thio-LISICON sintering? Optimize Solid Electrolyte Purity

- How does a sputtering machine work? Achieve Atomic-Level Precision for Your Coatings

- What are the challenges of welding stainless steel? Overcome Warping, Sensitization, and Contamination