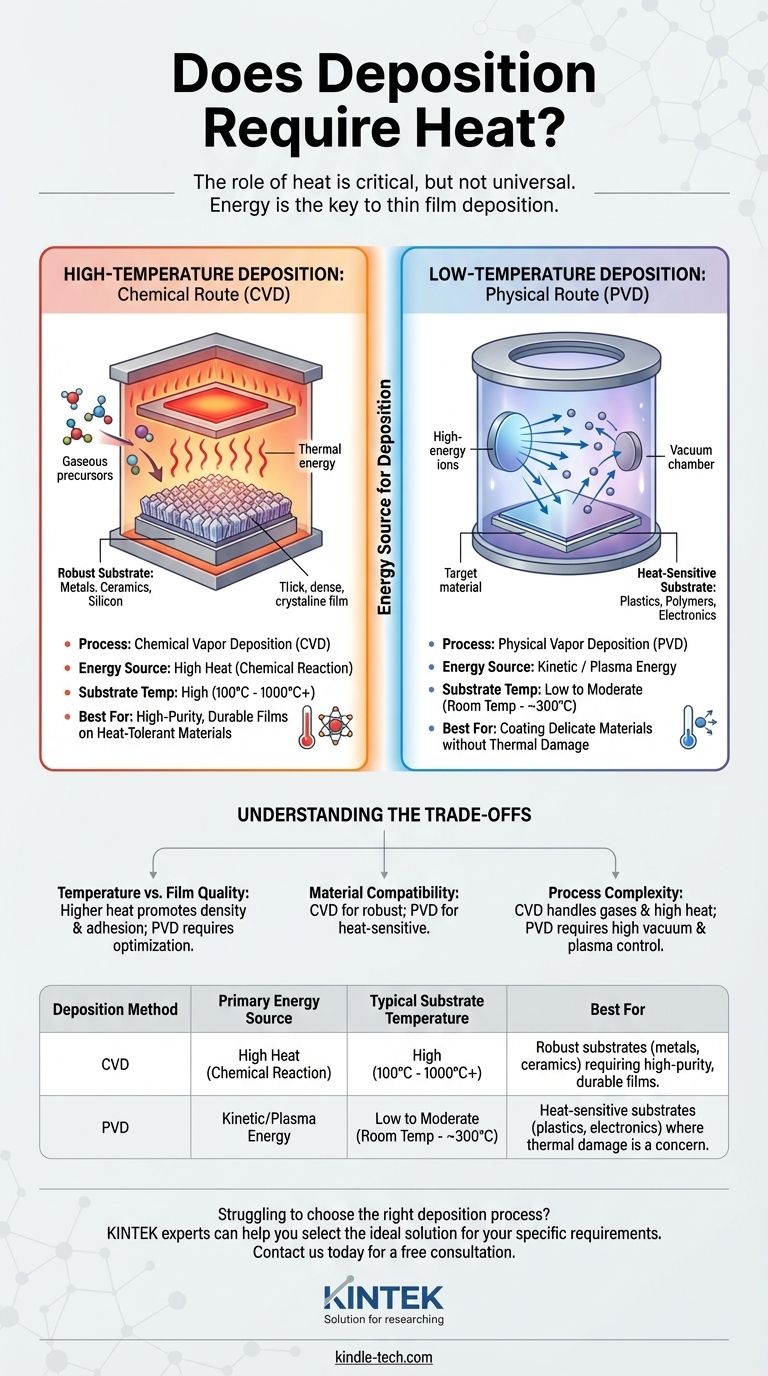

The role of heat in deposition is critical, but not universal. While many widely-used industrial processes, such as Chemical Vapor Deposition (CVD), rely on high temperatures to function, it is not a requirement for all deposition techniques. Other methods use different forms of energy, such as kinetic or plasma energy, to create thin films, allowing for deposition on heat-sensitive materials.

Your question touches on the central challenge of thin film engineering: how to energize a material to deposit it onto a surface without damaging that surface. The answer is that heat is just one tool; the choice between high-heat and low-heat methods depends entirely on the material you are coating and the film quality you need to achieve.

The Fundamental Role of Energy in Deposition

To understand why heat is so often used, we must first understand the basic goal of deposition. It is a process of adding a thin layer of one material onto another, atom by atom.

What is Deposition?

At its core, deposition involves taking a source material (the precursor or target) and transforming it into a vapor. This vapor then transports across a chamber and condenses onto a target surface (the substrate), forming a solid, uniform thin film.

Why Energy is Necessary

Energy is required for two key steps in this process. First, energy is needed to liberate atoms or molecules from the source material and turn them into a vapor. Second, once those atoms arrive at the substrate, energy helps them arrange into a dense, well-adhered film. Heat is simply the most common and intuitive form of this energy.

High-Temperature Deposition: The Chemical Route (CVD)

Chemical Vapor Deposition (CVD) is a powerful technique that exemplifies the use of high heat. It is an industry standard for creating extremely high-quality, durable films.

How Chemical Vapor Deposition (CVD) Works

In CVD, one or more volatile precursor gases are introduced into a reaction chamber. The substrate inside this chamber is heated to a very high temperature. This thermal energy triggers a chemical reaction on the substrate's surface, causing the gases to decompose and deposit the desired solid film.

The Benefit of Heat: High-Quality Films

The high temperatures used in CVD (often several hundred to over a thousand degrees Celsius) promote the growth of highly pure, dense, and crystalline films with excellent adhesion to the substrate. The heat provides the activation energy needed for strong chemical bonds to form.

Low-Temperature Deposition: The Physical Route (PVD)

For applications involving heat-sensitive substrates like plastics, polymers, or delicate electronics, high-temperature processes are not an option. This is where Physical Vapor Deposition (PVD) becomes essential.

How Physical Vapor Deposition (PVD) Works

PVD describes a family of techniques that use physical, rather than chemical, means to create a vapor. These methods transfer energy to the source material kinetically or through targeted heating in a vacuum, allowing the substrate to remain at or near room temperature.

Sputtering: Using Kinetic Energy

In sputtering, a high-energy ion (like Argon) is accelerated to bombard a solid source material called a "target." This impact acts like a subatomic sandblaster, physically knocking atoms off the target. These ejected atoms then travel through a vacuum and coat the substrate. The substrate itself is not intentionally heated.

Evaporation: A Lower-Heat Alternative

In thermal evaporation, the source material is heated in a high vacuum until it evaporates, creating a vapor cloud that condenses on the cooler substrate. While the source is hot, the substrate can be kept at a much lower temperature, making this a viable method for more sensitive materials than CVD allows.

Understanding the Trade-offs

Choosing between a high-heat or low-heat process involves balancing performance, material compatibility, and cost. There is no single "best" method.

Temperature vs. Film Quality

As a general rule, higher substrate temperatures promote better film quality, density, and adhesion. Low-temperature PVD processes can still produce excellent films, but may require careful optimization of other parameters (like vacuum level or ion energy) to achieve results comparable to high-temperature CVD.

Material and Substrate Compatibility

This is the most critical factor. CVD is ideal for robust substrates like metals, ceramics, and silicon wafers that can withstand high heat. PVD is the definitive choice for temperature-sensitive substrates like plastics, organic electronics (OLEDs), and medical implants.

Process Complexity

Both methods have their own complexities. CVD requires handling potentially hazardous precursor gases and managing extreme temperatures. PVD requires sophisticated high-vacuum systems and precise control over plasma or electron beams.

Making the Right Choice for Your Goal

Your decision must be guided by the limitations of your substrate and the performance requirements of your film.

- If your primary focus is the highest possible film purity and durability on a heat-tolerant substrate (like silicon or metal): High-temperature CVD is often the superior choice for its ability to create strongly bonded, dense films.

- If your primary focus is coating a heat-sensitive material (like plastic or an electronic component): PVD methods like sputtering are the necessary solution, as they do not require heating the substrate.

- If you need a balance of good film quality on a moderately sensitive substrate: PVD via thermal evaporation or a specialized technique like Plasma-Enhanced CVD (PECVD) can provide an effective middle ground.

Ultimately, understanding that heat is just one form of energy used in deposition empowers you to select the process that fits your specific goal.

Summary Table:

| Deposition Method | Primary Energy Source | Typical Substrate Temperature | Best For |

|---|---|---|---|

| Chemical Vapor Deposition (CVD) | High Heat (Chemical Reaction) | High (100°C - 1000°C+) | Robust substrates (metals, ceramics) requiring high-purity, durable films. |

| Physical Vapor Deposition (PVD) | Kinetic/Plasma Energy | Low to Moderate (Room Temp - ~300°C) | Heat-sensitive substrates (plastics, electronics) where thermal damage is a concern. |

Struggling to choose the right deposition process for your specific substrate and performance requirements?

At KINTEK, we specialize in lab equipment and consumables for precise thin film deposition. Whether you need the high-quality films of a CVD system or the gentle processing of a PVD system for delicate materials, our experts can help you select the ideal solution.

Contact us today to discuss your application, and let us help you achieve the perfect thin film for your research or production needs.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs