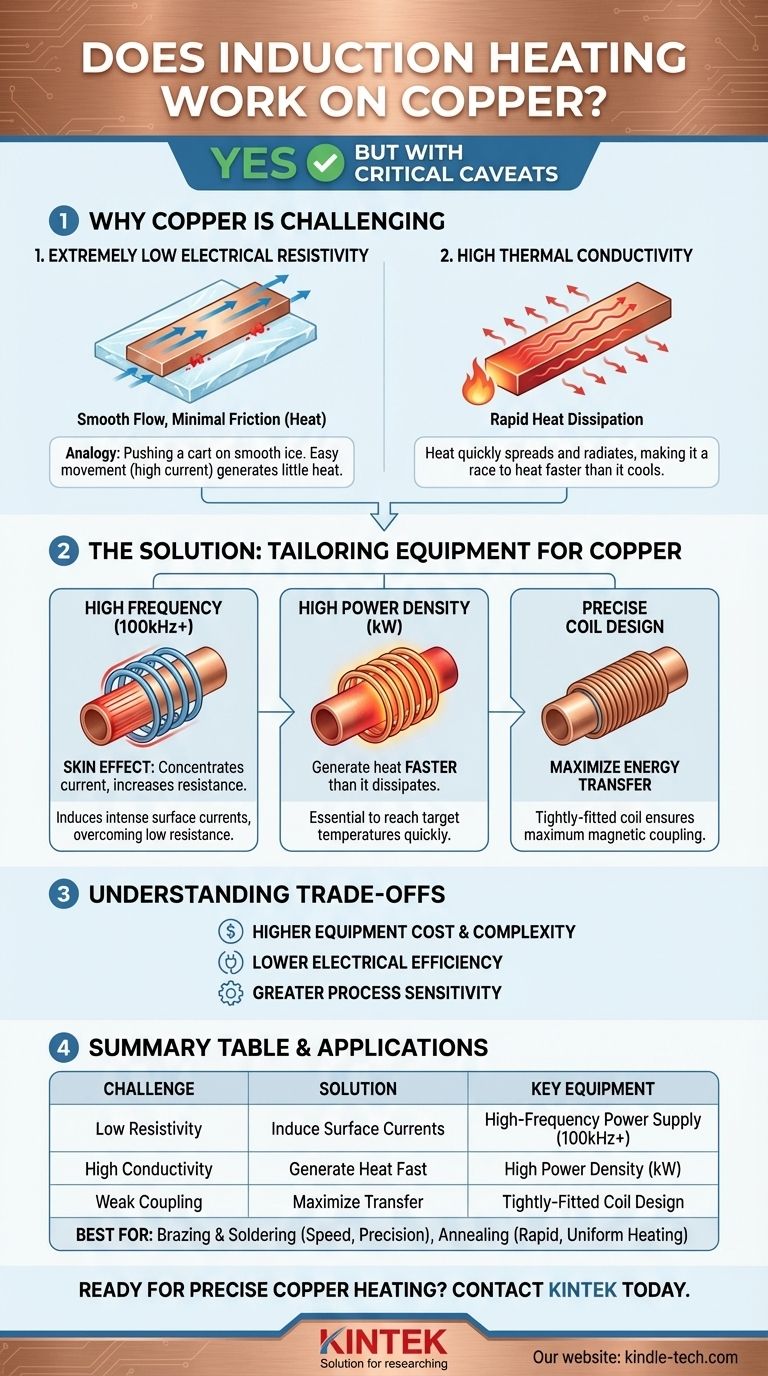

Yes, but with critical caveats. Induction heating absolutely works on copper, but its unique properties make it significantly more challenging and resource-intensive to heat than magnetic materials like steel. Success depends entirely on using the correct equipment—specifically, systems that operate at a much higher frequency and power level to overcome copper's natural resistance to this heating method.

The very properties that make copper an excellent electrical conductor—low electrical resistance and high thermal conductivity—are the same properties that make it difficult to heat with induction. Overcoming this requires a specialized, high-frequency induction system to generate heat faster than the copper can conduct it away.

The Physics of Heating Copper via Induction

To understand why copper is challenging, you must first understand the core principle of induction. The process is not about magnetic attraction; it's about electrical resistance.

How Induction Heating Works

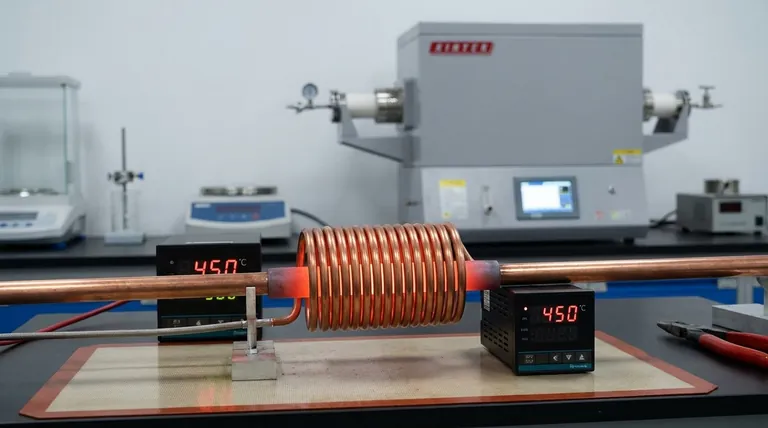

An induction heater uses an alternating current running through a copper coil to create a powerful, oscillating magnetic field. When a conductive workpiece (like a piece of steel or copper) is placed inside this field, the field induces electrical currents, called eddy currents, to flow within the material.

The material's own electrical resistance fights against the flow of these eddy currents, generating precise and rapid heat. This is known as Joule heating or I²R losses.

The Challenge: Copper's Extremely Low Resistivity

Steel has relatively high electrical resistivity, which makes it easy to heat. Think of it like pushing a heavy cart on a rough, gravelly surface—your effort easily creates friction and heat.

Copper, by contrast, is one of the best electrical conductors in existence, meaning it has extremely low resistivity. Pushing the same cart on a perfectly smooth, icy surface is a better analogy. Your effort makes the cart move very fast (high current flow), but it generates very little friction (heat).

The Second Challenge: High Thermal Conductivity

Compounding the problem is copper's excellent thermal conductivity. As soon as you begin generating heat in one area, the copper efficiently spreads that heat throughout the part and radiates it into the environment. You are in a race to pump in heat faster than the copper can get rid of it.

The Solution: Tailoring the Equipment for Copper

Overcoming copper's natural properties requires a specific engineering approach. You cannot use the same induction system designed for steel and expect good results.

The Critical Role of Frequency

The solution to low resistivity is to use a high-frequency magnetic field. A higher frequency induces larger and more intense eddy currents. It also takes advantage of the "skin effect," where high-frequency currents tend to flow only in a thin layer on the surface of the conductor.

Concentrating the current in this thin skin effectively increases the material's resistance in that small area, finally allowing for efficient heat generation. For copper, this typically requires frequencies from 100 kHz to several hundred kHz or even higher, compared to the 1-50 kHz often used for steel.

The Need for Higher Power

To win the race against copper's thermal conductivity, the system must have a high power density. A higher power rating (measured in kilowatts) allows the system to generate heat much faster than the workpiece can dissipate it, enabling you to reach target temperatures for applications like brazing, soldering, or annealing.

Importance of Coil Design

With non-magnetic materials like copper, the magnetic field does not get "concentrated" in the part as it does with steel. Therefore, the induction coil must be designed to couple very tightly with the workpiece, meaning it must be very close to the part's surface to ensure the maximum amount of magnetic energy is transferred.

Understanding the Trade-offs

Choosing induction for copper involves acknowledging several key considerations that differ from working with steel.

Equipment Cost and Complexity

High-frequency induction power supplies are generally more complex and expensive than the lower-frequency units used for most steel applications. The investment is greater, which must be justified by the process benefits like speed and repeatability.

Lower Electrical Efficiency

Even with the right equipment, the process of heating copper is inherently less energy-efficient than heating steel. More energy is required to bring copper to the same temperature, which translates to higher operational costs.

Process Sensitivity

Heating copper with induction is more sensitive to variables like coil positioning and part consistency. A small change in the distance between the coil and the part can have a much larger impact on the heating time and final temperature than it would with a steel part.

Making the Right Choice for Your Application

Selecting the right heating approach depends entirely on your specific goal, material, and production needs.

- If your primary focus is brazing or soldering copper components: A properly specified high-frequency induction system is an excellent choice, offering unmatched speed, precision, and repeatability.

- If your primary focus is annealing or stress-relieving copper: Induction works very well, providing rapid and uniform heating when the system is correctly matched to the part geometry.

- If your primary focus is melting large quantities of copper: Induction melting furnaces are standard in industry, but they are highly specialized systems designed specifically to handle the challenges of non-ferrous metals.

- If you are on a tight budget or only need to heat copper occasionally: Other methods, like a simple torch, may be more cost-effective, though they sacrifice the precision, control, and safety of induction.

By understanding the physics at play, you can select the right technology and configure it for precise, predictable results with your copper workpiece.

Summary Table:

| Challenge | Solution | Key Equipment Requirement |

|---|---|---|

| Low Electrical Resistivity | Induce intense surface currents | High-Frequency Power Supply (100kHz+) |

| High Thermal Conductivity | Generate heat faster than it dissipates | High Power Density (kW) |

| Weak Magnetic Coupling | Maximize energy transfer | Tightly-Fitted, Precision Coil Design |

Ready to achieve precise, rapid heating for your copper applications?

KINTEK specializes in high-frequency induction heating systems engineered to overcome the unique challenges of working with non-magnetic metals like copper. Whether you are brazing, soldering, or annealing, our lab equipment delivers the power and control you need for repeatable, efficient results.

Contact our experts today to discuss your specific copper heating requirements and discover the right solution for your laboratory.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Double Plate Heating Press Mold for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Touchscreen Automatic Vacuum Heat Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the application of melting furnace? From Casting to Purification

- What is the process of vacuum arc degassing? Achieve Ultra-Clean, High-Performance Steel

- What is the difference between arc melting and induction melting? Power vs. Precision for Your Metal Melting Needs

- How does induction furnace work? Achieve Fast, Clean, and Efficient Metal Melting

- Why is water used in an induction furnace? To prevent catastrophic coil overheating and failure

- What is the temperature of an induction furnace? Understanding Capabilities from 1250°C to 2000°C+

- What metals can be melted in an induction furnace? Unlock the Power to Melt Virtually Any Metal

- What is the use of induction heating? A Guide to Fast, Precise, and Clean Industrial Heating