Yes, induction heating works with copper, but its effectiveness depends heavily on using the right equipment and process parameters. Because copper has very high electrical conductivity, it presents a unique challenge compared to heating magnetic metals like steel, requiring higher frequencies and power to generate heat efficiently.

While perfectly viable, heating copper with induction is fundamentally a game of overcoming its natural properties. Unlike steel, copper's low electrical resistance and non-magnetic nature mean you must use higher frequencies and power to generate the necessary heat for processes like melting, brazing, or annealing.

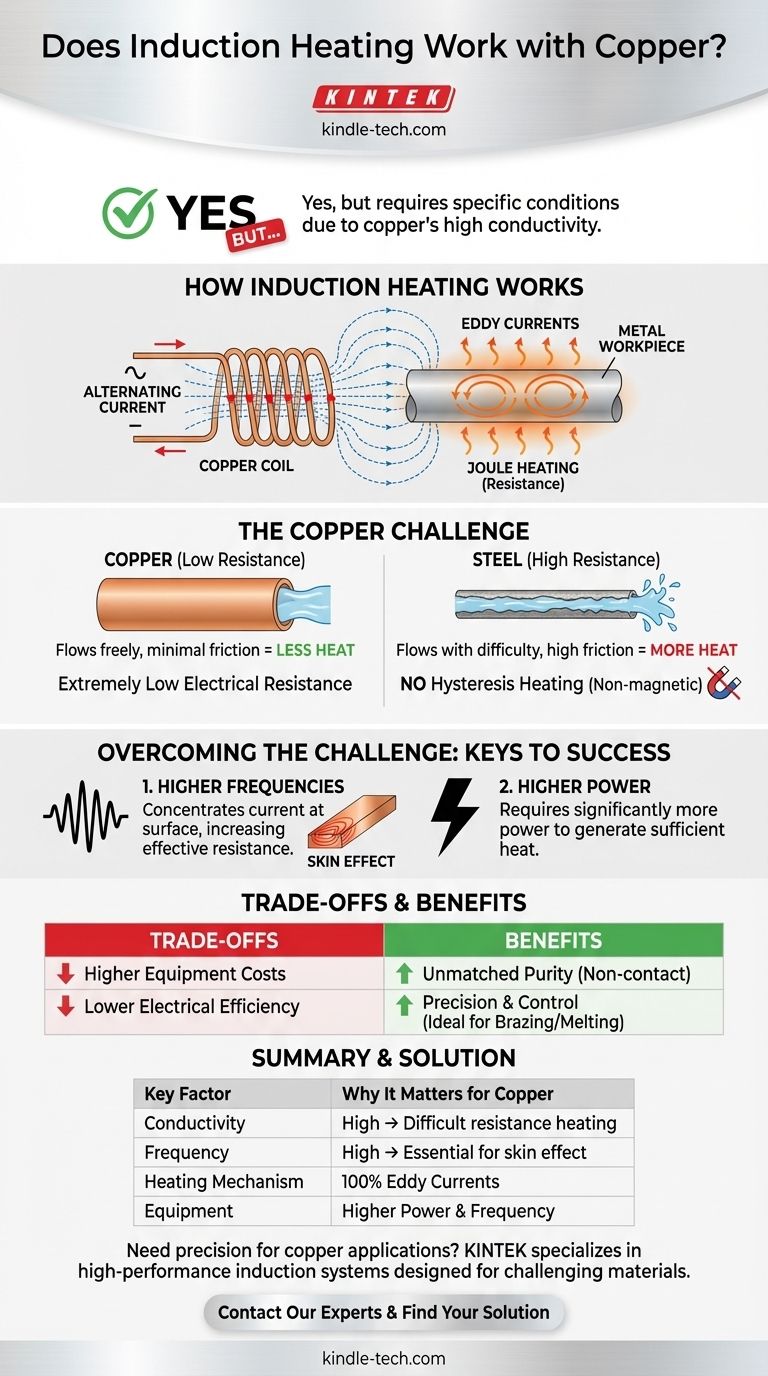

How Induction Heating Works

To understand the specific challenges with copper, we must first grasp the basic principles of induction.

The Core Principle: Magnetic Fields and Eddy Currents

Induction heating uses an alternating electric current flowing through a copper coil to create a powerful, changing magnetic field. When a conductive workpiece, like a piece of copper, is placed within this field, the field induces electrical currents within the metal. These are called eddy currents.

Generating Heat Through Resistance

The heat itself is generated by the material's electrical resistance to the flow of these eddy currents. As the currents swirl inside the metal, they encounter resistance, which causes the material to heat up rapidly—a phenomenon known as Joule heating.

The Unique Challenge of Heating Copper

The very properties that make copper an excellent electrical conductor also make it inherently difficult to heat with induction.

Copper's Extremely Low Resistance

Copper has one of the lowest electrical resistivities of any common metal. This means the induced eddy currents can flow through it very easily, with minimal opposition.

Think of it like water flowing through a pipe. A high-resistance metal like steel is a narrow, rough pipe that creates a lot of friction (heat) as water passes through. Copper is a very wide, smooth pipe where water (current) flows with almost no friction (heat).

The Absence of Hysteresis Heating

For ferromagnetic metals like iron and steel, a secondary heating effect occurs called hysteresis heating. The rapid switching of the magnetic field causes the metal's magnetic domains to flip back and forth, creating internal friction and thus additional heat.

Copper is not magnetic. It does not benefit from this effect, meaning 100% of the heating must come from eddy currents alone, making the process less efficient than with steel.

Overcoming the Challenge: The Keys to Success

Successfully heating copper requires a system designed to compensate for its low resistance and non-magnetic nature.

Higher Frequencies are Essential

To generate sufficient heat in a low-resistance material, you must use a higher operating frequency. Higher frequencies cause the eddy currents to become more concentrated near the surface of the material (a phenomenon called the "skin effect").

This concentration forces a large amount of current through a smaller cross-section of the metal, which effectively increases the resistance and generates heat much more rapidly. This is why the reference mentions medium-frequency furnaces, as lower frequencies would be highly ineffective.

The Need for Higher Power

Simply put, you need a power supply capable of driving significantly larger currents into the workpiece to achieve the desired temperature in a reasonable time. A system designed for steel will often be underpowered for an equivalent task with copper.

Understanding the Trade-offs

While effective, using induction for copper involves important considerations.

Higher Equipment Costs

Induction systems that can operate at the higher frequencies and power levels required for copper are typically more complex and expensive than their lower-frequency counterparts used for steel.

Lower Electrical Efficiency

Because you are fighting against copper's natural conductivity, the overall wall-plug energy efficiency of heating copper is lower than for steel. More energy is lost in the process of generating the intense fields required.

Unmatched Purity and Control

On the other hand, induction is a non-contact heating method. For applications like melting high-purity copper or creating specific alloys, it is ideal. There is no contamination from fuel or electrodes, and the stirring action of the eddy currents promotes a homogenous melt with minimal material loss.

Making the Right Choice for Your Application

Your decision should be guided by your end goal.

- If your primary focus is melting high-purity copper or alloys: Induction is an excellent choice for its cleanliness, speed, and mixing action, provided you invest in a correctly specified furnace.

- If your primary focus is brazing or soldering copper parts: Induction offers unmatched speed, precision, and repeatability, making it ideal for high-volume manufacturing where quality is critical.

- If your primary focus is simple heating on a limited budget: Be aware that the initial investment for a suitable induction system will be higher than for other methods, but it may pay off in speed and control.

By understanding copper's unique electrical properties, you can effectively leverage induction heating for fast, clean, and precise results.

Summary Table:

| Key Factor | Why It Matters for Copper |

|---|---|

| Electrical Conductivity | Extremely high, making it difficult to generate heat via resistance. |

| Required Frequency | High frequency is essential to concentrate current and generate heat (skin effect). |

| Heating Mechanism | Relies 100% on eddy currents; no magnetic hysteresis heating. |

| Equipment Needs | Higher power and frequency capabilities than systems designed for steel. |

Need to melt, braze, or heat copper with precision and purity?

KINTEK specializes in high-performance lab equipment, including induction heating systems designed for challenging materials like copper. Our expertise ensures you get the right frequency and power for fast, clean, and controlled results.

Contact our experts today to discuss your specific copper heating application and find the perfect solution for your laboratory.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Lab-Scale Vacuum Induction Melting Furnace

- Double Plate Heating Press Mold for Lab

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- What material is used for making heating element? Choose the Right Alloy for Your Application

- What is the maximum temperature for a SiC heating element? Unlock the Key to Longevity and Performance

- What is SiC elements? The Ultimate High-Temperature Heating Solution

- What is a silicon carbide heating element? Unlock Extreme Heat for Industrial Processes

- What is silicon carbide rod heated to high temperature used as? A Premier Heating Element for Extreme Environments