Yes, the primary purpose of milling is to reduce particle size. Milling is a mechanical process that breaks down solid materials into smaller pieces. By applying forces like impact, shear, or compression, it transforms larger particles, granules, or chunks into finer powders with specific characteristics.

Milling is the fundamental technique for particle size reduction. However, the ultimate goal is not just to make things smaller, but to gain precise control over a material's physical properties, which dictates its performance, handling, and consistency in any application.

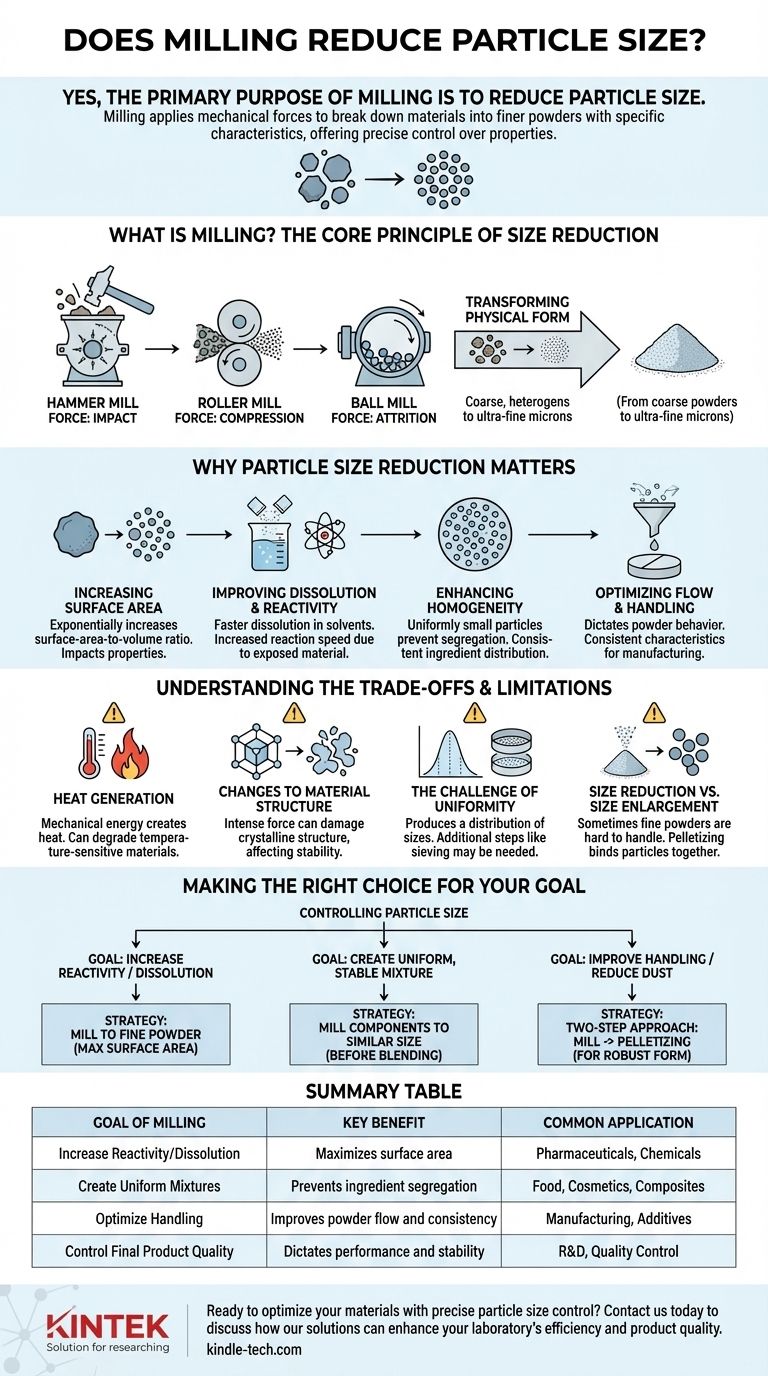

What is Milling? The Core Principle of Size Reduction

Milling, also known as grinding or comminution, is a foundational process in materials science. It is the mechanism by which mechanical energy is used to fracture solid structures.

The Application of Force

The core of any milling process is the application of force sufficient to break down the material. Different types of mills specialize in different forces, such as the impact of a hammer mill, the compression of a roller mill, or the attrition found in a ball mill.

Transforming Physical Form

This process takes a coarse, often heterogeneous material and transforms it into a powder with a much smaller particle size. The degree of size reduction can be controlled to produce particles ranging from coarse powders to ultra-fine particles measured in microns.

Why Particle Size Reduction Matters

Reducing particle size is rarely the end goal itself. Instead, it is a critical step performed to achieve one or more specific performance enhancements.

Increasing Surface Area

As a particle is broken down, its surface-area-to-volume ratio increases exponentially. This is the single most important consequence of milling, as it directly impacts many other properties.

Improving Dissolution and Reactivity

A larger surface area allows a substance to dissolve much faster in a solvent. It also increases the speed of chemical reactions, as more of the material is exposed and available to react at any given time.

Enhancing Homogeneity

When creating a mixture or blend, having uniformly small particles is essential. It allows for a much more consistent distribution of ingredients and prevents segregation, where different components separate over time due to variations in size and density.

Optimizing Flow and Handling

The size and shape of particles dictate how a powder behaves—whether it flows freely or tends to clump. Milling helps create powders with consistent characteristics for downstream manufacturing processes like tablet pressing or packaging.

Understanding the Trade-offs and Limitations

While powerful, milling is a process that must be carefully controlled. The energy applied to the material can have unintended consequences.

Heat Generation

The mechanical energy used in milling generates significant heat. For temperature-sensitive materials, such as certain pharmaceuticals or polymers, this can lead to degradation, melting, or a loss of efficacy.

Changes to Material Structure

The intense force of milling can damage the crystalline structure of a material, creating amorphous (non-crystalline) regions. This can negatively affect the material's stability, shelf-life, and behavior.

The Challenge of Uniformity

Milling produces a distribution of particle sizes, not a single uniform size. Achieving a very narrow distribution often requires additional steps, such as sieving or air classification, to separate out particles that are too large or too small.

Size Reduction vs. Size Enlargement

Sometimes, the goal is the opposite. Extremely fine powders can be difficult to handle, dusty, and may flow poorly. In these cases, processes like pelletizing or granulation are used to bind small particles together into larger, more manageable forms.

Making the Right Choice for Your Goal

Controlling particle size is about selecting the right process to achieve a specific outcome.

- If your primary focus is increasing reaction speed or dissolution rate: Milling to achieve a fine powder with maximum surface area is your most effective strategy.

- If your primary focus is creating a uniform, stable mixture: Milling individual components to a similar particle size is a critical first step before blending.

- If your primary focus is improving material handling and reducing dust: You may need a two-step approach: use milling to create uniform base particles, then use a size-enlargement process like pelletizing to build them into a more robust form.

Ultimately, controlling particle size through processes like milling is fundamental to controlling your final product's performance and quality.

Summary Table:

| Goal of Milling | Key Benefit | Common Application |

|---|---|---|

| Increase Reactivity/Dissolution | Maximizes surface area | Pharmaceuticals, Chemicals |

| Create Uniform Mixtures | Prevents ingredient segregation | Food, Cosmetics, Composites |

| Optimize Handling | Improves powder flow and consistency | Manufacturing, Additives |

| Control Final Product Quality | Dictates performance and stability | R&D, Quality Control |

Ready to optimize your materials with precise particle size control?

At KINTEK, we specialize in providing the right lab equipment and consumables to meet your specific milling and particle size reduction needs. Whether you are developing new pharmaceuticals, creating uniform composite materials, or improving product consistency, our expertise can help you achieve superior results.

Contact us today to discuss how our solutions can enhance your laboratory's efficiency and product quality.

Visual Guide

Related Products

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Low-Temperature Water-Cooled Touchscreen Vibratory Ultrafine Pulverizer

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Twin Screw Extruder Plastic Granulation Machine

People Also Ask

- What is the process of cryogenic ball milling? Achieve Superior Nanomaterial Synthesis

- What are cryogenic ground spices? Unlock Maximum Flavor with Advanced Grinding Technology

- What is the difference between a pulverizer and a ball mill? Choose the Right Grinding Technology

- What is the mechanism of a grinding machine? Achieve Superior Precision and Surface Finishes

- What is cryogenic machining used for? Process Unmachinable Materials with Extreme Cold