To be direct, PVD plating does not fade in the traditional sense of losing color from sun exposure or chemical reaction. Instead of fading, this incredibly durable coating can, over a very long period of intense use, wear down through physical abrasion. The process used to apply PVD creates a molecular bond that is exceptionally hard and resistant to the elements that cause traditional platings and paints to degrade.

The core issue is not one of fading, but of mechanical wear. Physical Vapor Deposition (PVD) coatings are among the most durable finishes available, and their failure is a matter of extreme physical abrasion, not a gradual loss of color.

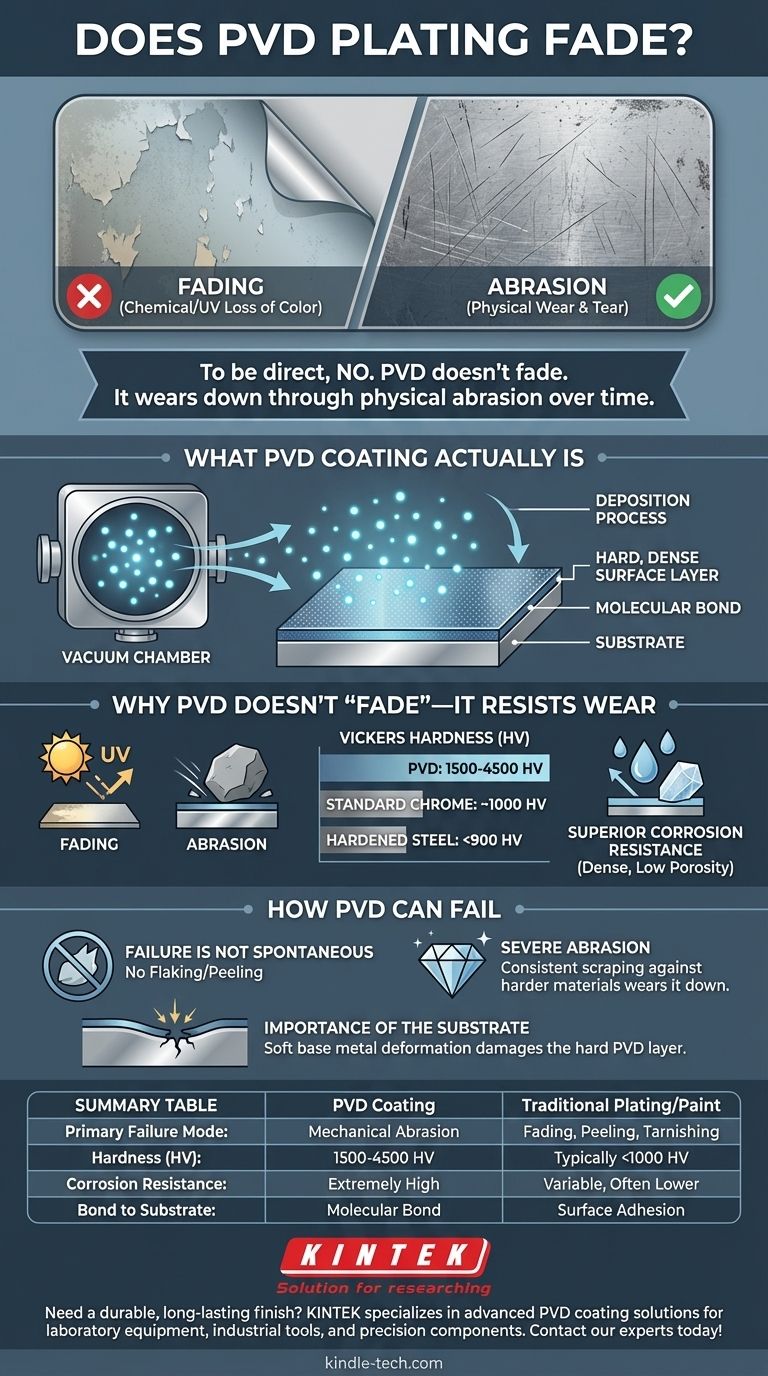

What PVD Coating Actually Is

To understand its durability, you first need to understand the process. PVD is fundamentally different from painting or traditional electroplating.

The Deposition Process

An item is placed in a vacuum chamber where a solid material—often a durable metal like titanium or zirconium—is vaporized into a plasma of atoms or ions. These particles are then deposited onto the item, forming a thin, dense, and exceptionally hard surface layer.

The Result: A Molecular Bond

This process doesn't just lay a coating on top of the surface; it bonds the new layer to the substrate at a molecular level. Think of it less like a coat of paint and more like an atomically bonded new skin that is integrated with the original material.

Why PVD Doesn't 'Fade'—It Resists Wear

The term "fading" is often a misnomer when discussing PVD. The mechanism of failure is entirely different from what you might expect with other finishes.

Understanding Fading vs. Abrasion

Fading typically implies a chemical change that alters color, often caused by UV light or oxidation. PVD coatings are highly resistant to this. Instead, the only significant threat to a PVD coating is abrasion—the physical scratching or wearing away of the material itself.

Extreme Hardness as a Defense

PVD coatings have a Vickers hardness between 1500 and 4500 HV. For context, standard chrome plating is around 1000 HV, and hardened tool steels are often below 900 HV. This exceptional hardness makes the surface incredibly difficult to scratch.

Superior Corrosion Resistance

The PVD process creates an extremely dense coating with low porosity. This density significantly enhances its resistance to sweat, salt, and other environmental factors that would quickly corrode or tarnish lesser finishes.

Understanding the Trade-offs: How PVD Can Fail

While PVD is a superior technology, no coating is indestructible. Understanding its limits is key to managing expectations.

Failure is Not Spontaneous

A PVD coating will not flake, peel, or fall off on its own. Its strong bond to the substrate prevents this type of failure, which is common in cheaper plating methods. If you see a PVD coating failing, it is almost certainly due to an external force.

The Real Culprit: Severe Abrasion

The coating can be compromised if it is consistently scraped against a material that is harder than it is. While resistant to daily bumps and scrapes, grinding it against rock, diamond, or other very hard, sharp surfaces will eventually wear it down, often starting at the sharpest edges of an item.

The Importance of the Substrate

The PVD coating is only a few microns thick. If the base metal underneath is very soft and deforms from an impact, the hard PVD layer on top can be damaged along with it. A quality PVD finish relies on a strong and stable base material.

Making the Right Choice for Your Goal

Your satisfaction with a PVD-coated product depends entirely on its intended use and your expectations for its lifespan.

- If your primary focus is daily-wear durability (e.g., watches, jewelry): PVD is an outstanding choice that will dramatically outperform traditional gold plating or other finishes, looking new for years.

- If your primary focus is aesthetic appeal on a low-contact item: A PVD finish will likely last indefinitely, as it will never face the kind of abrasion required to wear it down.

- If your primary focus is extreme industrial use (e.g., tools, blades): PVD is the industry standard for extending component life, but it should be viewed as a high-performance, sacrificial layer that will eventually wear out under constant, heavy use.

Ultimately, a PVD coating's lifespan is a direct function of its remarkable resistance to physical wear, not a gradual decline in color.

Summary Table:

| Property | PVD Coating | Traditional Plating/Paint |

|---|---|---|

| Primary Failure Mode | Mechanical Abrasion | Fading, Peeling, Tarnishing |

| Hardness (Vickers) | 1500 - 4500 HV | Typically < 1000 HV |

| Corrosion Resistance | Extremely High (Dense, Low Porosity) | Variable, Often Lower |

| Bond to Substrate | Molecular Bond | Surface Adhesion |

Need a durable, long-lasting finish for your products or components? KINTEK specializes in advanced PVD coating solutions for laboratory equipment, industrial tools, and precision components. Our coatings provide superior hardness and corrosion resistance, extending the life and performance of your products. Contact our experts today to discuss how PVD can solve your wear and durability challenges!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- 30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications