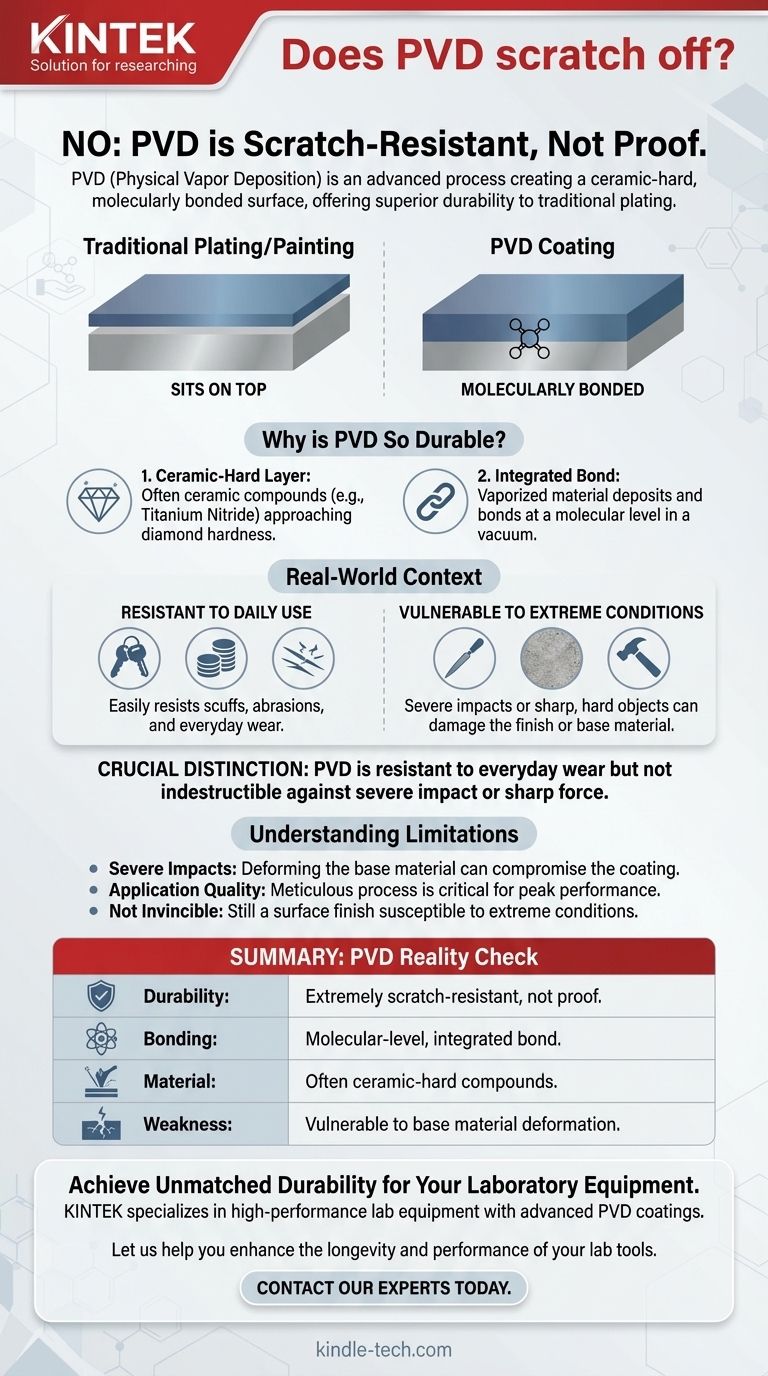

To be direct, the idea that PVD coating easily scratches off is a common misconception. PVD (Physical Vapor Deposition) is an advanced process that molecularly bonds a thin film of metal or ceramic to a surface, creating a finish that is exceptionally hard and far more durable than traditional plating or painting.

The crucial distinction is that PVD is scratch-resistant, not scratch-proof. While it offers superior protection against everyday wear, no coating is truly indestructible against a sufficiently hard or sharp impact.

What Makes PVD So Durable?

To understand PVD's resilience, you have to understand what it is. Unlike paint, it's not a layer sitting on top of the surface; it's integrated with it.

It's a Bonded, Ceramic-Hard Layer

The PVD process takes place in a high-tech vacuum chamber where a solid material is vaporized into plasma. This vapor is then deposited onto the target object, creating a new, super-hardened surface layer that is bonded at a molecular level.

It's Not a Paint or Plating

Many of the most popular PVD coatings, like Titanium Nitride, are ceramic compounds. These materials are incredibly hard—in some cases, approaching the hardness of a diamond—which is why they resist scratches so effectively.

Durability in Real-World Context

While PVD is by far one of the most durable coatings available today, its performance depends on the circumstances.

Scratch Resistance vs. Scratch Proof

PVD will easily resist scuffs from keys, rubbing against a wall, or the general abrasions of daily use. However, a sharp, hard object like a diamond file or a forceful scrape against rough concrete can still damage the finish.

The Base Material Matters

The coating is only a thin film. If a PVD-coated item suffers a severe impact that dents or deforms the underlying metal (like stainless steel), the PVD coating will be compromised along with it. The coating won't peel off, but it can be chipped or cracked if the foundation beneath it fails.

Understanding the Trade-offs

PVD is a top-tier finish, but it is essential to have realistic expectations and understand its limitations.

Severe Impacts Are the Enemy

The primary weakness of any surface coating is a significant, focused impact. While PVD excels at resisting widespread abrasion, a hard drop onto an abrasive surface can cause damage.

The Application Process is Critical

A high-quality PVD finish depends on a meticulous application process. The base material must be perfectly clean and prepared for the coating to bond correctly. A poorly executed PVD application will not have the same durability as one performed to high standards.

The Myth of Invincibility

Because of its hardness, PVD is often marketed as being indestructible. It is the best-in-class solution for durability, but it's crucial to remember that it is still a surface finish that can be damaged under extreme conditions.

Making the Right Choice for Your Goal

PVD offers a significant upgrade in durability over almost any other finishing option. Your decision should be based on your specific use case.

- If your primary focus is everyday durability for items like watches, jewelry, or faucets: PVD is an outstanding choice that will keep your items looking new far longer than traditional finishes.

- If your primary focus is extreme use in tactical or industrial settings: PVD is still one of the best options available, but you must expect that severe impacts and extreme abrasion can eventually compromise the finish.

Ultimately, PVD coating represents the pinnacle of modern surface finishing, providing a level of hardness and scratch resistance that is second to none.

Summary Table:

| Aspect | PVD Coating Reality |

|---|---|

| Durability | Extremely scratch-resistant, not scratch-proof. |

| Bonding | Molecular-level bond, not a superficial layer. |

| Material | Often a ceramic-hard compound like Titanium Nitride. |

| Weakness | Can be damaged by severe impacts deforming the base material. |

Achieve Unmatched Durability for Your Laboratory Equipment

PVD coatings are the gold standard for protecting surfaces from daily wear and tear. KINTEK specializes in providing high-performance lab equipment and consumables, ensuring your instruments are protected with the most advanced coatings available.

Let us help you enhance the longevity and performance of your lab tools.

Contact our experts today to discuss how our PVD-coated solutions can benefit your specific laboratory needs.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What are the advantages and disadvantages of hot stamping? Unlock Ultra-High Strength for Automotive Parts

- What is vacuum lamination? Achieve a Flawless, Durable Finish on Complex Shapes

- What is the purpose of laminating? Protect and Enhance Your Documents for Long-Term Use

- What is the advantage by using hot press forming? Achieve Stronger, More Complex Parts

- What is hot press moulding? Achieve Superior Density and Complex Shapes with Heat and Pressure