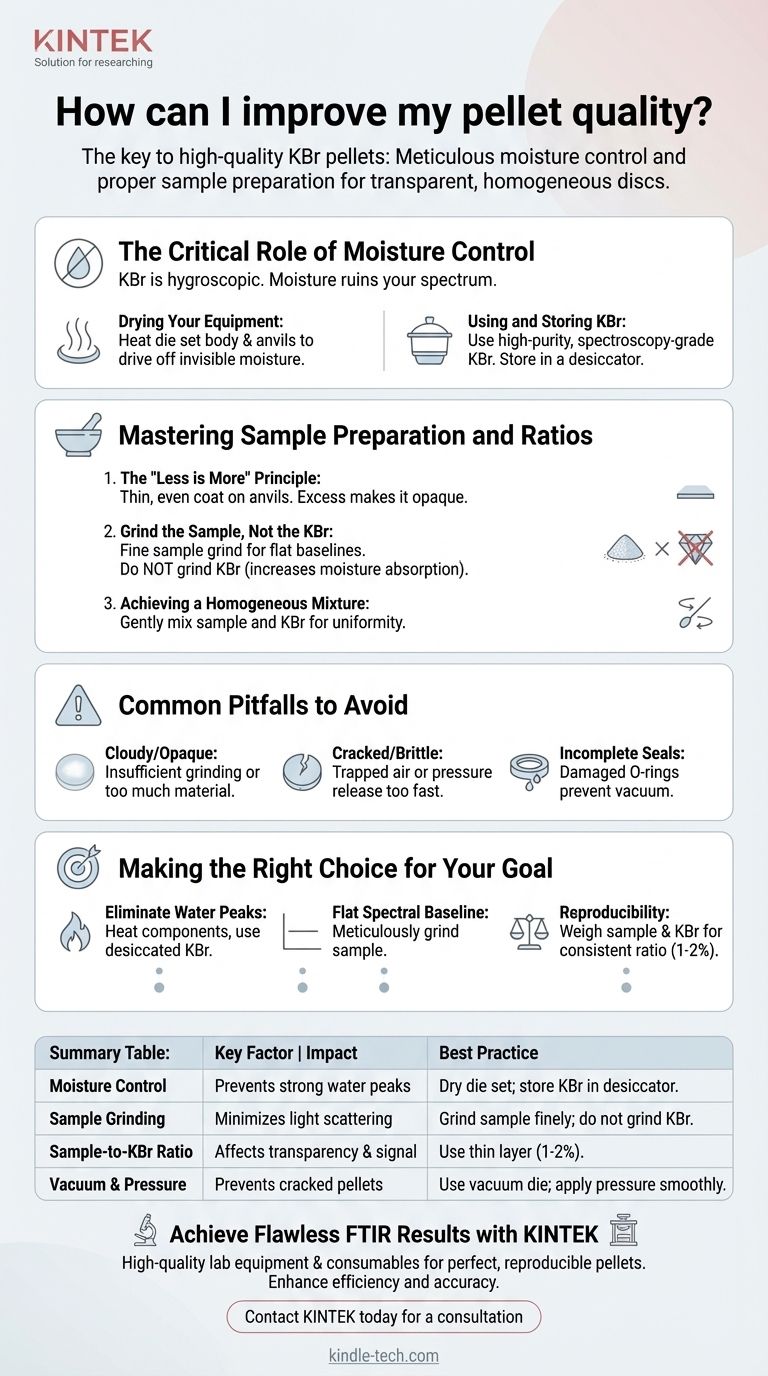

The key to high-quality KBr pellets lies in meticulous moisture control and proper sample preparation. Success depends on ensuring your KBr powder, sample, and equipment are completely dry and at the same temperature. Furthermore, the ratio of sample to KBr and the physical grinding technique are critical for creating a transparent, homogeneous disc suitable for analysis.

The ultimate goal is not just to press a solid disc, but to create an optically clear medium where your finely dispersed sample can be analyzed without interference from moisture or light scattering. Every step in the process is designed to eliminate these two primary sources of error.

The Critical Role of Moisture Control

Potassium bromide (KBr) is hygroscopic, meaning it readily absorbs moisture from the atmosphere. This moisture is the primary enemy of a high-quality infrared spectrum.

Why Moisture Ruins Your Spectrum

Water has very strong and broad absorption bands in the infrared region. If present in your pellet, these water peaks can completely obscure the spectral features of your actual sample, rendering your data useless.

Drying Your Equipment

Before you begin, gently heat the die set body and the anvils. This simple step drives off any condensed moisture that is invisible to the naked eye. An oven or a heat gun can be used for this purpose.

Using and Storing KBr

Always use high-purity, spectroscopy-grade KBr powder. Crucially, it must be kept perfectly dry. Storing your KBr powder in a desiccator is a standard best practice.

Mastering Sample Preparation and Ratios

The physical preparation of the sample and its mixture with the KBr matrix directly impacts the clarity of the final pellet and the quality of the data.

The "Less is More" Principle

Avoid using too much KBr powder. You only need enough to thinly and evenly coat the anvils of the die. An excessively thick pellet becomes opaque and can diminish the signal that reaches the detector.

Grind the Sample, Not the KBr

This is a critical, often misunderstood, step. You must grind your solid sample into a very fine powder, ideally with an agate mortar and pestle. This minimizes light scattering (known as the Christiansen effect), which can cause distorted, sloping baselines in your spectrum.

Conversely, do not grind the KBr powder itself. Grinding dramatically increases its surface area, causing it to absorb atmospheric moisture much more rapidly.

Achieving a Homogeneous Mixture

After your sample is finely ground, add the dry KBr powder. Mix the two components gently, without aggressive grinding, until the sample is evenly dispersed throughout the KBr matrix. The goal is uniformity, not further particle size reduction.

Common Pitfalls to Avoid

Even with careful preparation, several common issues can arise. Understanding the cause is key to preventing them.

Cloudy or Opaque Pellets

This is almost always caused by one of two things: insufficiently ground sample particles that scatter light, or simply using too much material overall. The pellet should be translucent, not opaque white.

Cracked or Brittle Pellets

Cracks often form due to trapped air. Using a vacuum die set is the best way to prevent this, as it removes air pockets while the pellet is being formed. Applying and releasing the pressure on the press too quickly can also cause the pellet to fracture.

Incomplete Die Set Seals

If you use a vacuum die, ensure it is assembled correctly and that all O-rings and seals are in good condition. A poor seal will prevent you from pulling an effective vacuum, defeating the purpose of the equipment.

Making the Right Choice for Your Goal

Your specific analytical goal should guide where you focus your efforts.

- If your primary focus is eliminating water peaks: Heat all components of your die set and use KBr powder directly from a drying oven or desiccator.

- If your primary focus is a flat spectral baseline: Meticulously grind your sample to the finest possible powder to minimize light scattering effects.

- If your primary focus is reproducibility: Carefully weigh your sample and KBr to maintain a consistent ratio (typically 1-2% sample by weight) for every pellet you make.

By treating pellet preparation as a precise analytical technique rather than a simple chore, you gain complete control over the quality of your spectroscopic data.

Summary Table:

| Key Factor | Impact on Pellet Quality | Best Practice |

|---|---|---|

| Moisture Control | Prevents strong water peaks that obscure sample spectrum. | Dry die set; store KBr in a desiccator. |

| Sample Grinding | Minimizes light scattering for a flat baseline. | Grind sample finely; do not grind KBr powder. |

| Sample-to-KBr Ratio | Affects pellet transparency and signal strength. | Use a thin layer (typically 1-2% sample by weight). |

| Vacuum & Pressure | Prevents cracked pellets from trapped air. | Use a vacuum die; apply pressure smoothly. |

Achieve Flawless FTIR Results with KINTEK

Struggling with cloudy pellets, water peaks, or inconsistent results? The precision of your KBr pellet preparation is fundamental to the quality of your spectroscopic data. KINTEK specializes in high-quality laboratory equipment and consumables, including reliable pellet presses and dies designed to help you achieve perfect, reproducible pellets every time.

Let us help you enhance your lab's efficiency and data accuracy. Our experts can guide you to the right equipment for your specific needs.

Contact KINTEK today for a consultation and take the first step toward superior sample analysis!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- kbr pellet press 2t

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- How much weight can a hydraulic press? The Real Measure is Tonnage, Not Machine Weight

- What affects the quality of pellets? A Guide to Achieving Durable, High-Density Biomass Pellets

- What is the necessity of using a laboratory hydraulic press for pre-pressing MoSi2-based composites? Ensure High Density

- What is a screw press used for? Efficient Liquid-Solid Separation for Waste & Processing

- What material can break a hydraulic press? Discover the Limits of Crushing Force

- What is the principle of forging press? Achieve Superior Strength with Controlled Metal Deformation

- What role does a laboratory hydraulic press play in the preparation of ferrotitanium oxide precursors? Key Functions

- What is XRF sample preparation? Achieve Accurate and Reliable Elemental Analysis