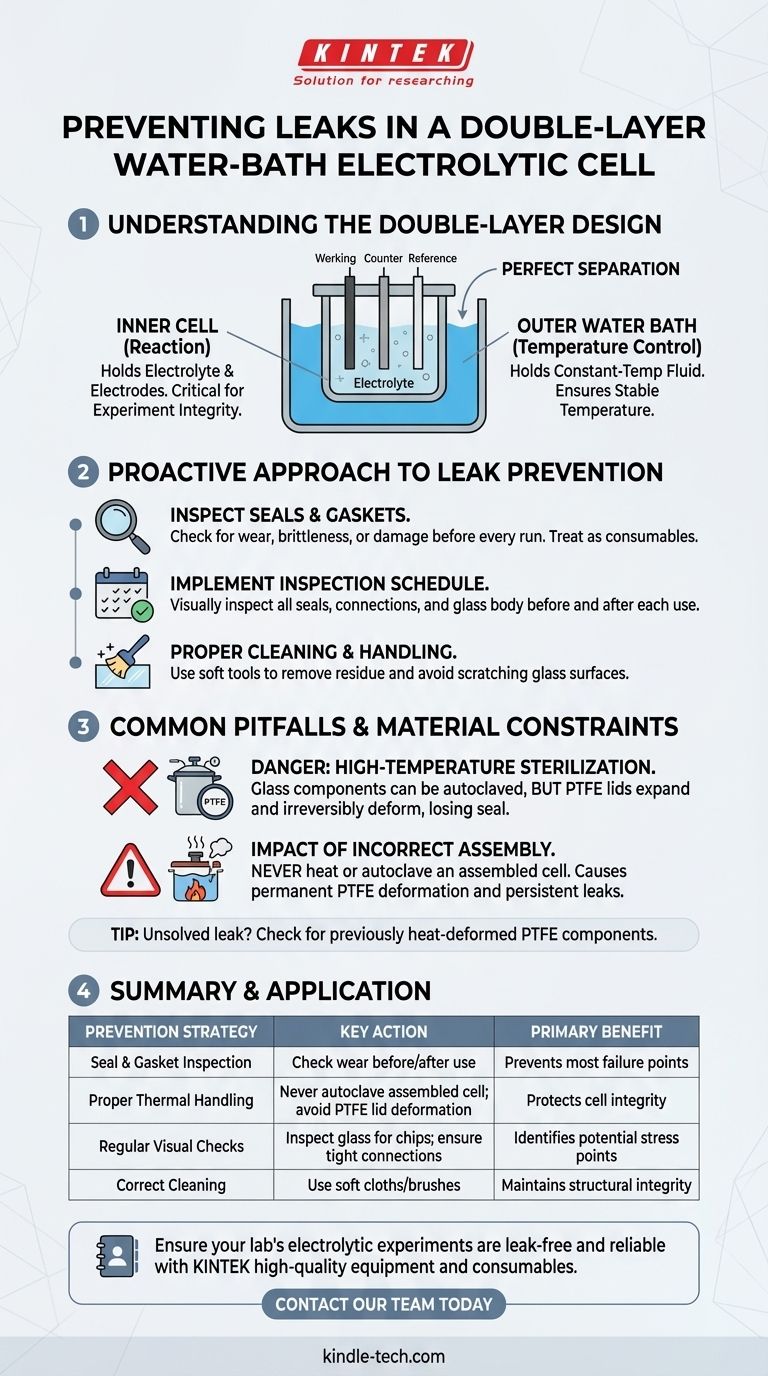

Preventing leaks in a double-layer electrolytic cell is a matter of both disciplined maintenance and a clear understanding of the equipment's material limitations. The solution lies in regular, focused inspections of all sealing components and avoiding operational errors, particularly those involving high temperatures, that can permanently compromise the cell's integrity.

The most common cause of persistent leaks is not just worn-out seals, but irreversible damage to components from improper handling, such as heating an assembled cell. True prevention requires understanding how your materials behave under different operating conditions.

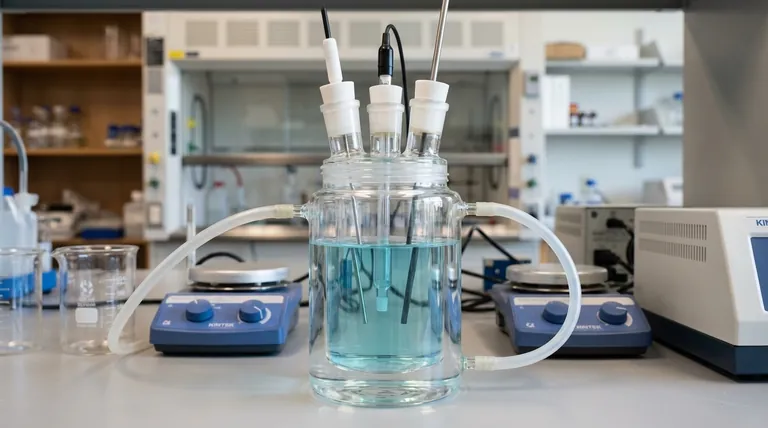

Understanding the Double-Layer Design

To prevent failures, you must first understand the purpose of the cell's construction. The design's entire value proposition is based on maintaining a perfect separation between two distinct environments.

The Role of the Inner Cell

The inner container is the heart of your experiment. It holds the electrolyte and the three-electrode system—the working, counter, and reference electrodes—where the actual electrolysis reaction occurs.

Any gas or liquid leak from this inner chamber directly compromises the integrity of your experiment, leading to inaccurate results.

The Function of the Outer Water Bath

The outer container serves as a jacket, holding a constant-temperature fluid. This water bath ensures the inner cell maintains a stable, uniform temperature.

This design is critical for temperature-sensitive reactions, as it mitigates heat generated during electrolysis and prevents local overheating on the electrode surfaces. A leak in this outer bath defeats its purpose, destroying temperature control and experimental repeatability.

A Proactive Approach to Leak Prevention

Leaks are rarely sudden catastrophes; they are typically the result of gradual degradation. A proactive maintenance schedule is the most effective strategy for preventing them.

The Critical Role of Seals and Gaskets

Seals, gaskets, and O-rings are the most common failure points. They are located at every connection point, including where electrodes are inserted and where the inner and outer glass components meet.

These components are designed to be replaced. Treat them as consumables and inspect them before every experimental run for signs of wear, brittleness, or damage.

Implementing a Regular Inspection Schedule

Your routine maintenance should be a formal process. Before and after each use, visually inspect all seals and connection points for a tight fit.

Also, examine the glass cell body itself. Even minor chips or scratches, especially near a sealing surface, can create a pathway for a leak under pressure or thermal stress.

Proper Cleaning and Handling

Always clean the cell's inner and outer surfaces after use to remove residual electrolyte and buildup. Use a soft cloth or brush to avoid scratching the glass.

Scratches can become stress concentration points over time, increasing the risk of cracks and catastrophic failure.

Common Pitfalls and Material Constraints

Many leaks are caused not by wear and tear, but by operational mistakes that fundamentally damage the equipment. Understanding material limitations is non-negotiable.

The Danger of High-Temperature Sterilization

While the glass components of the cell can often be autoclaved at 121°C, the Polytetrafluoroethylene (PTFE) lid cannot.

PTFE expands significantly when heated and may not return to its original shape and dimensions upon cooling. This irreversible deformation will prevent it from ever creating a proper seal again.

The Impact of Incorrect Assembly

Never heat or autoclave an assembled cell. Doing so will deform the PTFE lid, guaranteeing future water and gas leaks that cannot be fixed by simply replacing a gasket.

If you have a leak you can't seem to solve, consider the possibility that the lid or another PTFE component has been previously misshapen by heat.

Overlooking Operational Temperature

Strictly control the temperature of your water bath. While the design is meant to handle thermal gradients, extreme or rapid temperature changes can put stress on glass-to-seal interfaces, creating temporary or permanent leaks.

Also, always be mindful of safety. A leaking outer bath can spill high-temperature fluid, creating a significant burn hazard.

Applying This to Your Work

Your approach to leak prevention should be guided by your experimental goals and a respect for the equipment's design limitations.

- If your primary focus is experimental repeatability: Treat leak prevention as a core part of your methodology, as it ensures stable temperature and electrolyte concentration, which are essential for reliable data.

- If your primary focus is equipment longevity and safety: View routine seal inspection and proper thermal handling as the most important investment you can make to protect the apparatus from damage and prevent lab accidents.

Ultimately, maintaining a leak-free system comes from treating your electrolytic cell as the precise scientific instrument it is.

Summary Table:

| Prevention Strategy | Key Action | Primary Benefit |

|---|---|---|

| Seal & Gasket Inspection | Check for wear before/after each use | Prevents most common failure points |

| Proper Thermal Handling | Never autoclave assembled cell; avoid PTFE lid deformation | Protects cell integrity and sealing capability |

| Regular Visual Checks | Inspect glass for chips/scratches; ensure tight connections | Identifies potential stress points before they fail |

| Correct Cleaning | Use soft cloths/brushes to avoid scratching glass | Maintains structural integrity of the cell body |

Ensure your lab's electrolytic experiments are leak-free and reliable. KINTEK specializes in high-quality lab equipment and consumables, including seals and replacement parts for electrolytic cells. Our experts can help you maintain optimal performance and experimental repeatability. Contact our team today to discuss your specific laboratory needs and find the right solutions.

Visual Guide

Related Products

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Double-Layer Water Bath Electrolytic Electrochemical Cell

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Multifunctional Electrolytic Electrochemical Cell Water Bath Single Layer Double Layer

- Electrolytic Electrochemical Cell for Coating Evaluation

People Also Ask

- What inspection steps should be performed before using the electrolytic cell? A Guide to Safe & Accurate Experiments

- How should the electrolytic cell be connected to external equipment during an experiment? A Step-by-Step Guide

- How should faults with the electrolytic cell be handled? A Guide to Safe Diagnosis and Repair

- What regular inspection and maintenance activities are required for the electrolytic cell? Ensure Reliable Results & Extend Equipment Life

- How should a double-layer water-bath electrolytic cell be operated? A Step-by-Step Guide for Reliable Results