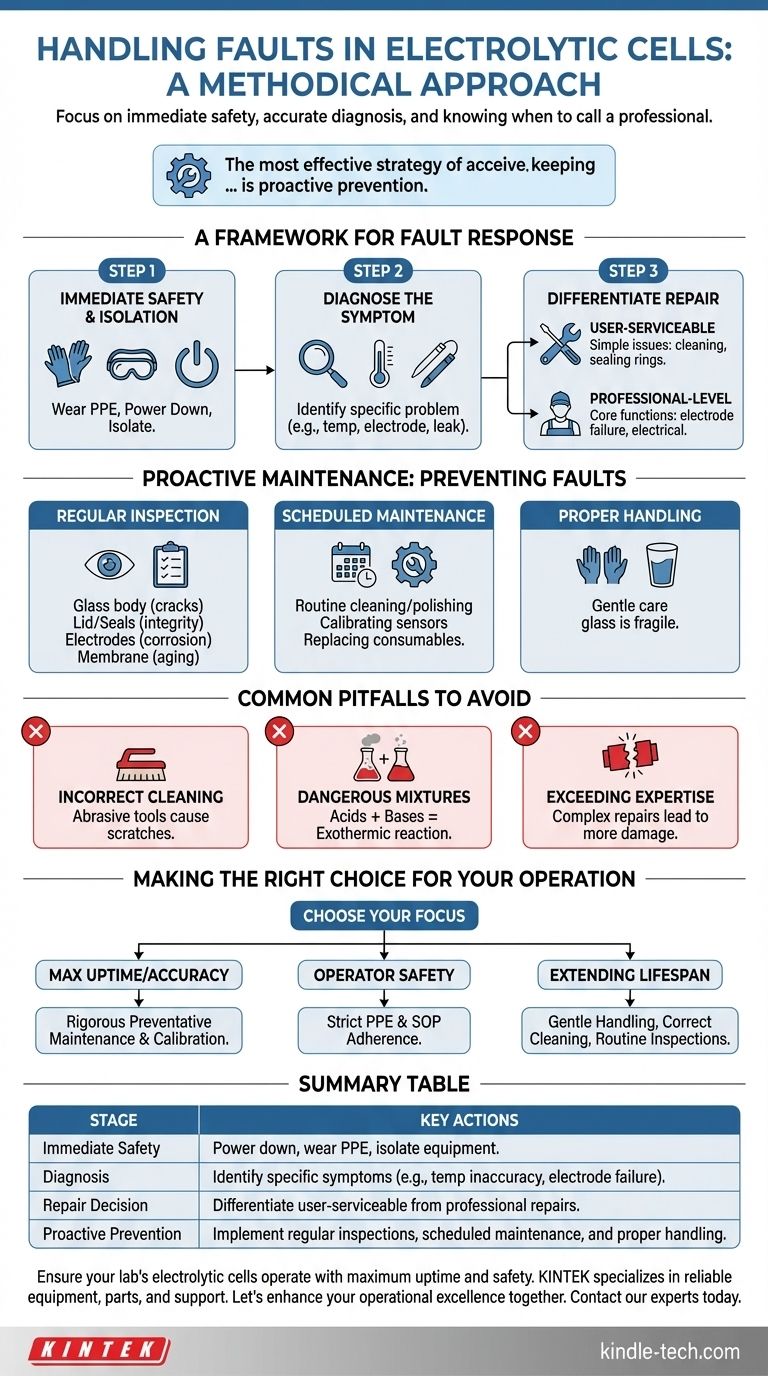

Handling faults with an electrolytic cell requires a methodical approach focused on immediate safety, accurate diagnosis, and a clear understanding of when to perform a repair yourself versus when to call a professional. For any malfunction, such as an electrode failure or inaccurate temperature control, the first step is to follow established safety protocols before attempting to diagnose the root cause.

The most effective strategy for handling faults is not reactive repair, but proactive prevention. While simple issues can be addressed by the user, true operational reliability comes from a disciplined regimen of regular inspection, careful handling, and knowing the limits of in-house maintenance.

A Framework for Fault Response

When a fault occurs, your response must be systematic. The goal is to safely restore function without causing further damage or creating a safety hazard.

Step 1: Immediate Safety and Isolation

Before any diagnosis, ensure all safety procedures are followed. This includes wearing appropriate personal protective equipment (PPE), such as gloves and goggles, especially when electrolyte or electrodes are involved. Safely power down and isolate the equipment if necessary.

Step 2: Diagnose the Symptom

Identify the specific problem. Is the temperature control inaccurate? Is an electrode visibly damaged or failing to perform? Is there a leak? Understanding the symptom is the first step toward identifying the cause.

Step 3: Differentiate User vs. Professional Repair

A critical decision point is determining who should perform the repair.

- User-Serviceable Faults: These are typically simple, mechanical issues. Examples include replacing a worn sealing ring to fix a leak or performing a standard cleaning procedure on a fouled electrode.

- Professional-Level Faults: These involve the core functionality of the cell. Issues like an electrode not working, persistent temperature inaccuracies, or suspected electrical problems require a trained technician to diagnose and repair correctly.

Proactive Maintenance: Preventing Faults Before They Start

The best way to handle a fault is to prevent it from happening. A consistent maintenance schedule is non-negotiable for reliable performance and longevity.

The Importance of Regular Inspection

Systematically inspect the cell based on its usage frequency. Check the glass cell body for any cracks or chips. Examine the lid and seals for integrity to ensure a tight fit. Inspect electrodes for signs of corrosion or physical damage, and check the ion exchange membrane for aging, discoloration, or blockage.

Scheduled Maintenance Tasks

Based on your inspections and the manufacturer's recommendations, perform periodic maintenance. This includes routine cleaning and polishing of electrodes, calibrating sensors, and replacing consumable components like the ion exchange membrane before they fail.

Proper Handling at All Times

Remember that the cell body is made of glass and is extremely fragile. It must be handled gently and carefully at all times to prevent breakage, which is an unrepairable fault.

Common Pitfalls to Avoid

Mistakes during maintenance can be more damaging than the original fault. Avoiding these common pitfalls is crucial for safety and equipment longevity.

Pitfall 1: Using Incorrect Cleaning Methods

Never use metal brushes or other abrasive tools to clean cell components. They can create microscopic scratches on surfaces, compromising performance and creating sites for future corrosion.

Pitfall 2: Dangerous Chemical Mixtures

Avoid mixing acids and bases (such as nitric acid and sodium hydroxide) during cleaning. This can trigger a dangerous exothermic reaction, posing a significant safety risk to both the operator and the equipment.

Pitfall 3: Attempting Repairs Beyond Your Expertise

While it can be tempting to try and fix a complex problem yourself, doing so without proper training often leads to greater damage. Attempting to repair core electronic or electrode issues can render the cell unusable and void its warranty.

Making the Right Choice for Your Operation

Your maintenance and fault response strategy should align with your operational priorities.

- If your primary focus is maximum uptime and accuracy: Implement a rigorous preventative maintenance and calibration schedule for all electrodes and sensors.

- If your primary focus is operator safety: Enforce strict adherence to PPE usage and standardized operating procedures, especially for handling electrolytes and performing cleaning tasks.

- If your primary focus is extending the cell's lifespan: Prioritize gentle handling, correct cleaning protocols, and routine inspections to prevent physical damage and material degradation.

By adopting this structured approach, you transform fault management from a reactive problem into a proactive pillar of operational excellence.

Summary Table:

| Fault Handling Stage | Key Actions |

|---|---|

| Immediate Safety | Power down, wear PPE, isolate equipment. |

| Diagnosis | Identify specific symptoms (e.g., temperature inaccuracy, electrode failure). |

| Repair Decision | Differentiate user-serviceable tasks (e.g., cleaning) from professional repairs (e.g., electrical issues). |

| Proactive Prevention | Implement regular inspections, scheduled maintenance, and proper handling. |

Ensure your lab's electrolytic cells operate with maximum uptime and safety.

KINTEK specializes in providing reliable lab equipment and consumables, including support for electrolytic cells. Our expertise helps you implement effective preventative maintenance strategies, source genuine replacement parts, and access professional technical support.

Let's enhance your operational excellence together. Contact our experts today to discuss your specific laboratory needs and how we can support your success.

Visual Guide

Related Products

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Electrolytic Electrochemical Cell with Five-Port

- Double-Layer Water Bath Electrolytic Electrochemical Cell

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- H Type Electrolytic Cell Triple Electrochemical Cell

People Also Ask

- What are the standard aperture sizes on the lid of the multifunctional electrolytic cell? Key Ports for Your Electrochemical Setup

- What is the typical experimental system used with a double-layer water-bath electrolytic cell? Achieve Precise Electrochemical Control

- What are the key features of the five-port water bath electrolytic cell? Precision Control for Electrochemical Experiments

- What is the overall structure of the H-type double-layer optical water bath electrolytic cell? Precision Design for Controlled Experiments

- What are the standard aperture specifications of the electrolytic cell? Key Sizes for Your Electrochemical Setup