To detect a vacuum furnace leak, the most common methods involve converting the furnace to a slight positive pressure and using a tracer gas detector, such as hydrogen or helium, to pinpoint the exact location. Alternatively, for furnaces under positive pressure during operation, you can monitor an online analyzer for a sudden increase in residual oxygen, which signals an atmospheric leak.

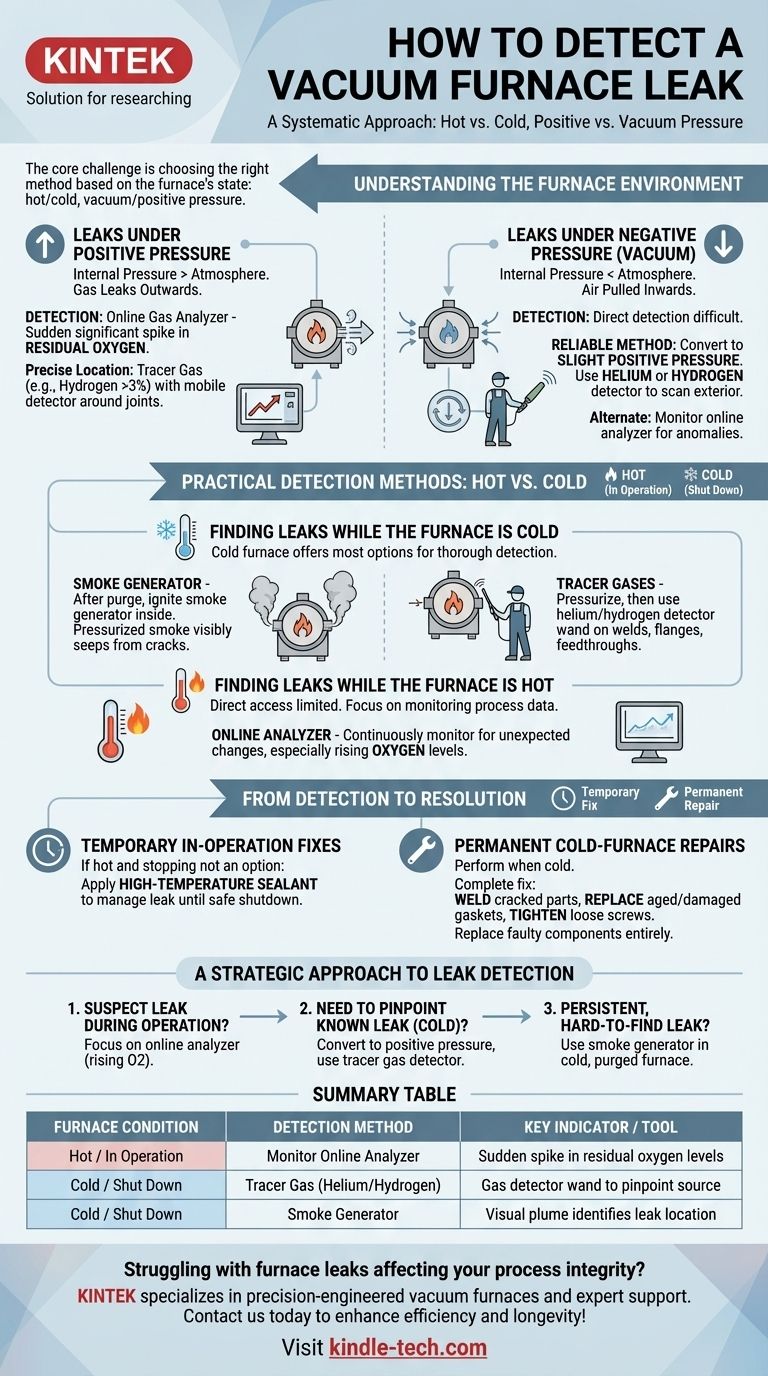

The core challenge in leak detection is not simply finding the leak, but choosing the right method based on the furnace's current state—whether it is hot or cold, and operating under vacuum or positive pressure. A systematic approach is crucial for both accurate diagnosis and effective repair.

Understanding the Furnace Environment

The first step in any leak detection strategy is to understand the pressure conditions of your furnace. The method you use will differ significantly depending on whether the system is under positive or negative pressure.

Leaks Under Positive Pressure

When the internal pressure is higher than the atmosphere, gas will leak outwards. This makes detection relatively straightforward.

An online gas analyzer is your first line of defense. A sudden and significant spike in residual oxygen readings is a clear indicator that air is being drawn into the circulation path from a leak in the furnace shell or piping.

For a more precise location, you can introduce a tracer gas. Ensuring the hydrogen level is above 3% and using a mobile hydrogen detector around joints and seals can verify the gas tightness of a specific section.

Leaks Under Negative Pressure (Vacuum)

Detecting a leak under vacuum is more challenging because air is being pulled into the furnace, not pushed out. Direct detection is often impossible.

The most reliable method is to convert the negative pressure into a slight positive pressure. Once the furnace is pressurized, you can use a hydrogen detector or a more sensitive helium leak detector to scan the exterior and find the source.

You can also observe the measurement data from your online analyzer for anomalies, though this is less direct than converting to positive pressure.

Practical Detection Methods: Hot vs. Cold

Your ability to physically access the furnace and the tools you can use are determined by whether it is in operation (hot) or shut down (cold).

Finding Leaks While the Furnace is Cold

A cold furnace offers the most options for thorough leak detection. This is the ideal state for pinpointing hard-to-find issues.

The smoke generator (or smoke bomb) method is highly effective for visualizing leaks. After the furnace has been purged of all combustibles, a smoke generator is ignited inside. The pressurized smoke will seep out of any cracks or faulty seals, creating a visible plume that makes the leak easy to spot.

Using tracer gases like helium or hydrogen is also a primary method for a cold furnace. After pressurizing the vessel, a detector wand is moved over all potential leak points, such as welds, flanges, and feedthroughs, to get a precise location.

Finding Leaks While the Furnace is Hot

Detecting leaks during operation is primarily about monitoring process data. Direct access is limited and unsafe.

Your main tool is the online analyzer. Continuously monitoring for unexpected changes in gas composition, particularly oxygen, will alert you to a developing leak in real-time.

From Detection to Resolution

Once a leak is identified, the repair strategy depends on operational needs and the severity of the issue. A temporary fix may be necessary to complete a cycle, but it should not be considered a permanent solution.

Temporary In-Operation Fixes

If a leak is discovered while the furnace is hot and stopping the cycle is not an option, a high-temperature sealant can be applied to the area as a temporary measure. This can manage the leak until the furnace can be safely shut down for a proper repair.

Permanent Cold-Furnace Repairs

Permanent repairs must be performed when the furnace is cold. Rushing this process or using substandard methods will only lead to future failures.

Proper resolution involves a complete fix: cracked parts should be welded, aged or damaged gaskets and snap rings must be replaced, and any loose screws should be tightened to specification. If a component has known technical issues, it should be replaced entirely.

A Strategic Approach to Leak Detection

Your response to a suspected leak should be methodical, starting with the least invasive methods and progressing as needed.

- If you suspect a leak during operation: Immediately focus on your online analyzer data for confirmation of an atmospheric leak, indicated by rising oxygen levels.

- If you need to pinpoint a known leak when the furnace is cold: Convert the system to positive pressure and use a hydrogen or helium leak detector for the most precise results.

- If you are dealing with a persistent, hard-to-find leak: Utilize a smoke generator in a cold, purged furnace for clear and unambiguous visual identification.

Ultimately, a proactive and systematic leak detection strategy is fundamental to protecting process integrity, ensuring product quality, and maintaining a safe operational environment.

Summary Table:

| Furnace Condition | Detection Method | Key Indicator / Tool |

|---|---|---|

| Hot / In Operation | Monitor Online Analyzer | Sudden spike in residual oxygen levels |

| Cold / Shut Down | Tracer Gas (Helium/Hydrogen) | Gas detector wand to pinpoint source |

| Cold / Shut Down | Smoke Generator | Visual plume identifies leak location |

Struggling with furnace leaks affecting your process integrity? KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision-engineered vacuum furnaces and expert support. Our solutions ensure reliable performance and minimal downtime. Contact us today (#ContactForm) to discuss how we can enhance your furnace's efficiency and longevity!

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Dental Porcelain Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How does a magnetron sputtering work? A Guide to High-Quality Thin Film Deposition

- How does a sputtering machine work? Achieve Atomic-Level Precision for Your Coatings

- What is magnetron sputtering machine? Precision Thin-Film Deposition for Advanced Materials

- What is the role of the hydraulic system in hot pressing? Achieve Maximum Material Density and Strength

- Why is sintering easier in the presence of a liquid phase? Unlock Faster, Lower-Temperature Densification