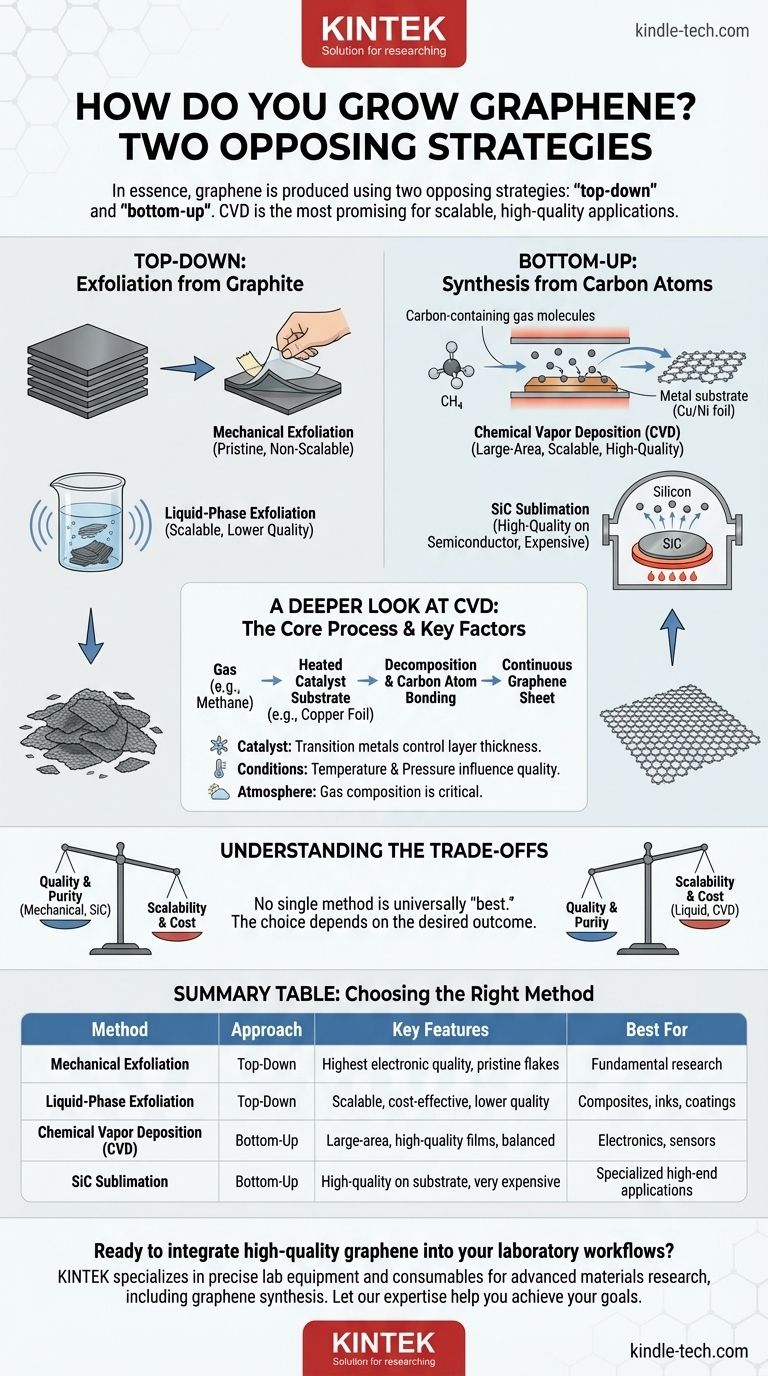

In essence, graphene is produced using two opposing strategies. These are "top-down" methods, where graphene is physically or chemically separated from bulk graphite, and "bottom-up" methods, where it is grown atom-by-atom on a substrate. Of these, Chemical Vapor Deposition (CVD) has emerged as the most promising and scalable technique for producing the large-area, high-quality graphene required for electronic applications.

The core challenge in graphene production is not simply making it, but making the right kind of graphene for a specific purpose. There is a direct and unavoidable trade-off between the scale and cost of production versus the ultimate electronic quality and purity of the material.

The Two Fundamental Approaches

Understanding graphene synthesis begins with classifying the methods into two high-level categories. Each approach starts from a different point and is suited for different end goals.

"Top-Down" Exfoliation: Starting with Graphite

This family of methods involves taking a piece of graphite—which is essentially a stack of countless graphene layers—and separating those layers.

Mechanical exfoliation is the original, Nobel-winning technique. It uses an adhesive material, famously scotch tape, to peel off progressively thinner layers from a graphite crystal until a single-atom-thick sheet is isolated. This method produces pristine, high-quality graphene flakes perfect for fundamental research but is not scalable for industrial use.

Liquid-phase exfoliation is a more scalable top-down method. Bulk graphite is submerged in a liquid and subjected to high-energy processes like sonication, which breaks the bonds between layers. While suitable for producing large quantities of graphene flakes for use in composites, inks, and coatings, the resulting material often has lower electrical quality and smaller flake sizes.

"Bottom-Up" Synthesis: Building from Carbon Atoms

Instead of breaking down graphite, "bottom-up" methods construct graphene from carbon-containing precursor molecules on a suitable surface.

Chemical Vapor Deposition (CVD) is the leading technique in this category. It involves exposing a heated catalyst substrate, typically a transition metal foil like copper or nickel, to a carbon-containing gas. At high temperatures, the gas decomposes, and carbon atoms arrange themselves into the characteristic honeycomb lattice of graphene on the catalyst's surface.

Sublimation of silicon carbide (SiC) is another high-quality method. When a SiC wafer is heated to very high temperatures in a vacuum, the silicon atoms sublime (turn directly into a gas), leaving behind a layer of carbon atoms that re-form into graphene on the surface. This produces high-quality graphene directly on a semiconducting substrate but is prohibitively expensive for most applications.

A Deeper Look at Chemical Vapor Deposition (CVD)

Because of its unique ability to balance quality with scale, CVD is the most critical growth method for the future of graphene-based electronics.

The Core Process

In a typical CVD process, a metal foil is heated in a vacuum furnace. A hydrocarbon gas, such as methane, is then introduced. The hot metal surface acts as a catalyst, breaking down the gas molecules and allowing the carbon atoms to bond together into a continuous graphene sheet.

Key Controlling Factors

The final quality of CVD graphene depends heavily on three factors: the catalyst, the growth conditions, and the atmosphere. Transition metals like copper are often used because they are cost-effective and their carbon solubility helps control the number of graphene layers that form.

Controlling Thickness

The choice of metal catalyst influences whether single-layer or multi-layer graphene is grown. On metals with low carbon solubility like copper, growth is self-limiting, typically stopping after a single layer forms. On metals with high carbon solubility like nickel, carbon can dissolve into the metal and then precipitate out upon cooling, forming multiple layers.

Understanding the Trade-offs

No single method for producing graphene is universally "best." The optimal choice is always a function of the desired outcome and acceptable compromises.

Quality vs. Scalability

This is the primary trade-off. Mechanical exfoliation provides the highest possible electronic quality but is entirely unscalable. Conversely, liquid-phase exfoliation offers mass production but with significant compromises in flake size and electrical performance.

Cost vs. Purity

CVD and SiC sublimation both produce high-quality graphene, but their costs are vastly different. The sublimation of SiC yields excellent material but its extreme cost limits its use to specialized, high-end applications. CVD offers a much more accessible balance, providing high-quality films over large areas at a manageable cost.

Making the Right Choice for Your Goal

Your application's specific needs will dictate the most appropriate method of graphene synthesis.

- If your primary focus is fundamental research on pristine material: Mechanical exfoliation remains the gold standard for its unmatched electronic quality.

- If your primary focus is mass production for composites, inks, or coatings: Liquid-phase exfoliation provides the necessary volume and is the most cost-effective choice.

- If your primary focus is creating large-area, high-quality films for electronics or sensors: Chemical Vapor Deposition (CVD) is the most viable and widely adopted technique.

Ultimately, selecting the best method for growing graphene is defined by the specific performance and production requirements of your application.

Summary Table:

| Method | Approach | Key Features | Best For |

|---|---|---|---|

| Mechanical Exfoliation | Top-Down | Highest electronic quality, pristine flakes | Fundamental research |

| Liquid-Phase Exfoliation | Top-Down | Scalable, cost-effective, lower electronic quality | Composites, inks, coatings |

| Chemical Vapor Deposition (CVD) | Bottom-Up | Large-area, high-quality films, balanced cost/performance | Electronics, sensors |

| SiC Sublimation | Bottom-Up | High-quality on semiconductor substrate, very expensive | Specialized high-end applications |

Ready to integrate high-quality graphene into your laboratory workflows? The right synthesis method is critical to your project's success, and so is having the right equipment. KINTEK specializes in providing the precise lab equipment and consumables needed for advanced materials research, including reliable solutions for graphene synthesis and characterization. Let our expertise help you achieve your research and production goals. Contact our team today to discuss your specific needs!

Visual Guide

Related Products

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is the temperature range of a graphite furnace? Unlock up to 3000°C for advanced materials processing.

- What are the applications of graphite material? Leveraging Extreme Heat and Precision for Industrial Processes

- What is the purpose of a graphite furnace? Achieve Extreme Temperatures for Advanced Materials

- Why graphite is used in furnace? Achieve Superior Heat Treatment & Energy Efficiency

- What are the advantages of graphite furnace? Achieve High-Temperature Precision and Purity