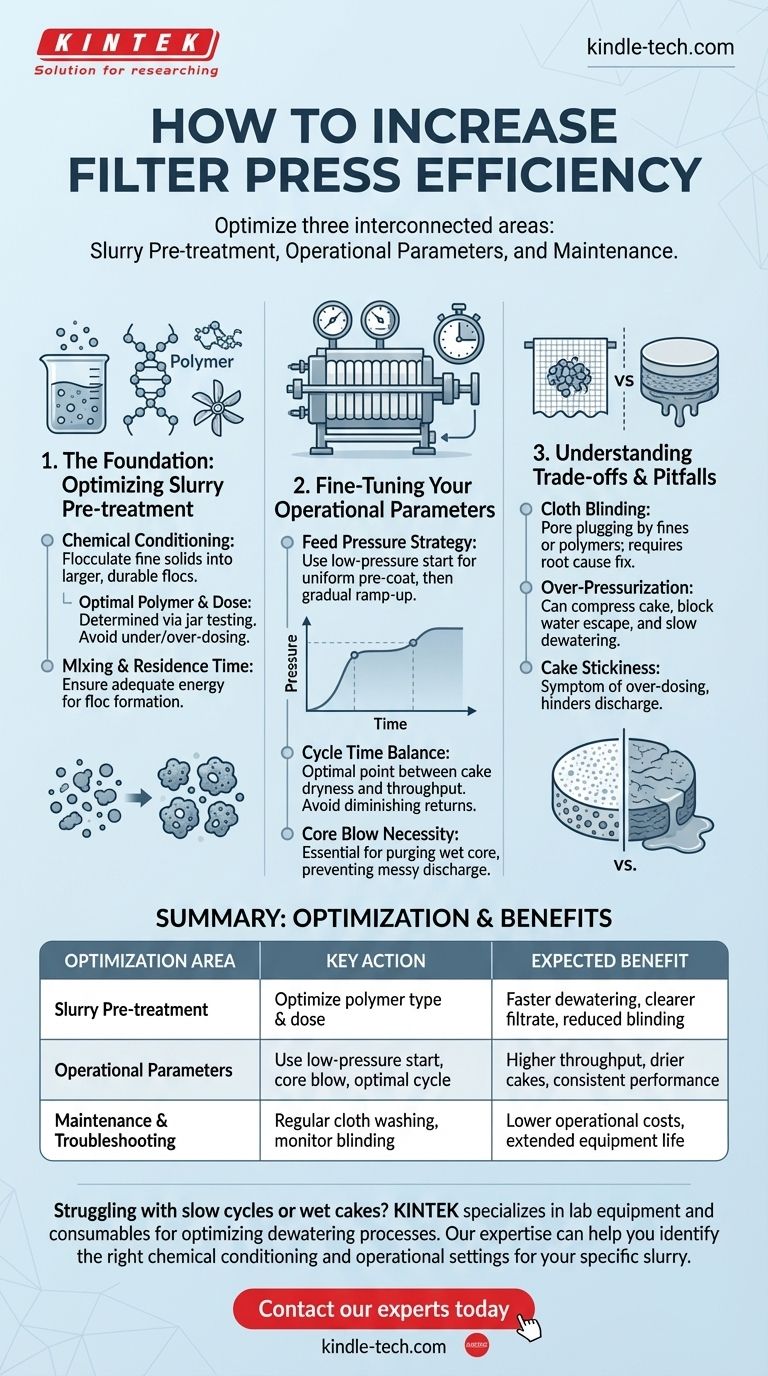

To increase filter press efficiency, you must optimize three interconnected areas: the chemical pre-treatment of the slurry, the operational parameters of the press itself, and a rigorous maintenance program. True efficiency is not achieved by focusing on just one of these elements, but by viewing the filter press as the final step in a complete dewatering system.

The single biggest mistake in optimizing a filter press is focusing only on the machine. True efficiency gains come from treating the cause, not the symptom, which almost always begins with how the slurry is conditioned before it ever enters the press.

The Foundation: Optimizing Slurry Pre-treatment

A filter press can only remove water that is available to be removed. The goal of pre-treatment is to condition the slurry by flocculating fine solids into larger, more durable particles, which release water easily.

The Critical Role of Chemical Conditioning

Most dewatering challenges originate here. Chemical conditioning, typically with polymers, is the process of binding small suspended particles into larger aggregates, or "flocs."

These larger flocs create a more porous and stable cake structure on the filter cloth. This porosity allows water to pass through more freely and quickly, dramatically reducing filtration time.

Finding the Optimal Polymer and Dose

There is no universal polymer. The correct chemistry depends on your specific slurry's particle size, surface charge, and composition.

Under-dosing results in poor solids capture, leading to cloudy filtrate and a wet, soupy cake. Over-dosing is equally damaging; it can create a slimy, impermeable barrier on the filter cloths, a condition known as cloth blinding.

The ideal dose is typically determined through jar testing in a lab, followed by fine-tuning on the operational system to achieve clear filtrate and a firm cake.

The Importance of Mixing and Residence Time

Simply adding the right chemical is not enough. The polymer needs adequate mixing energy and residence time to properly unfold and attach to solid particles.

Too little mixing fails to form strong flocs. Too much mixing (high shear) can break the flocs apart before they enter the press, undoing the work of the chemical.

Fine-Tuning Your Operational Parameters

Once the slurry is properly conditioned, you can optimize the press cycle for maximum efficiency.

Feed Pressure and Ramp-Up Strategy

Do not start the feed pump at maximum pressure. The initial phase of the cycle should use low pressure to allow a uniform, porous "pre-coat" of solids to build on the filter cloth.

Ramping up the pressure too quickly can drive fine particles deep into the cloth's weave, causing immediate blinding and slowing the entire cycle. A gradual pressure increase after the initial cake is formed is far more effective.

Cycle Time: A Balancing Act

Longer cycle times at high pressure will produce a drier cake, but at the cost of lower throughput. There is a point of diminishing returns where holding the press under pressure for an extra 30 minutes may only remove a tiny fraction of additional water.

The optimal cycle time balances your cake dryness requirements with your plant's overall production goals. Monitor cake dryness at different cycle lengths to find your operational sweet spot.

The Necessity of a Core Blow

If your press is equipped with it, a core blow is essential. This step uses compressed air to purge the central feed channel (the "core") of wet, un-dewatered slurry before the plates open.

Skipping this step results in a wet, messy cake discharge and can misrepresent the true dryness of the cake, as the wet core material falls out with the properly dewatered solids.

Understanding the Trade-offs and Pitfalls

Achieving efficiency means avoiding common mistakes that sabotage performance.

Cloth Blinding: The Silent Killer of Efficiency

Blinding is the plugging of the filter cloth pores by fines, grease, or polymer. It is the single most common cause of decreasing efficiency over time.

Symptoms include longer cycle times, wetter cakes, and high back-pressures. The solution is not more pressure; it's addressing the root cause, which is often improper chemical conditioning or the need for a cloth washing cycle.

Over-Pressurization and Cake Compressibility

For many types of slurries (especially organic sludges), applying excessive pressure simply compresses the cake, squeezing the pores shut and blocking the path for water to escape.

In these cases, more pressure actually slows down dewatering. Understanding the compressibility of your cake is key to setting the right pressure profile.

Cake Stickiness and Discharge Problems

A cake that is difficult to release from the cloth is a major operational bottleneck. This is not a mechanical problem with the press; it's a symptom of a suboptimal process.

The cause is almost always related to over-dosing with polymer or other upstream chemical imbalances, resulting in a slimy, sticky cake consistency.

Making the Right Choice for Your Goal

Your specific actions should align directly with your primary operational objective.

- If your primary focus is maximizing cake dryness: Concentrate on optimizing your polymer dose and allow for longer cycle times, ensuring you use the core blow function effectively.

- If your primary focus is maximizing plant throughput: Perfect your pre-treatment to create highly permeable flocs that dewater quickly, and accept a slightly shorter cycle time and correspondingly wetter cake.

- If your primary focus is reducing operational costs: Perform regular jar tests to avoid over-dosing expensive polymers and implement a preventative cloth washing schedule to extend cloth life and reduce energy consumption from long cycles.

Ultimately, mastering your filter press efficiency comes from understanding and controlling the entire system, not just the machine itself.

Summary Table:

| Optimization Area | Key Action | Expected Benefit |

|---|---|---|

| Slurry Pre-treatment | Optimize polymer type and dose via jar testing | Faster dewatering, clearer filtrate, reduced cloth blinding |

| Operational Parameters | Use low-pressure start, core blow, and optimal cycle times | Higher throughput, drier cakes, consistent performance |

| Maintenance & Troubleshooting | Regular cloth washing, monitor for blinding and stickiness | Lower operational costs, extended equipment life |

Struggling with slow cycles or wet cakes? KINTEK specializes in lab equipment and consumables for optimizing dewatering processes. Our expertise can help you identify the right chemical conditioning and operational settings for your specific slurry.

Contact our experts today to discuss how we can help you achieve maximum filter press efficiency and reduce your operational costs.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is the most efficient furnace type? Achieve Ultimate Comfort and Lower Energy Bills

- Does sintering increase porosity? How to Control Porosity for Stronger Materials

- What is the sequence of the heat treatment process? Master the 3 Stages for Perfect Material Properties

- What is the role of a laboratory mechanical stirrer in SA/PASP/RE preparation? Achieve Perfect Homogenization

- What type of samples can be characterized with IR spectroscopy? Analyze Solids, Liquids, and Gases

- What are the three factors of heat treatment? Master Temperature, Time & Cooling Rate

- What is the capacity of a plate and frame filter press? Understand the real-world throughput for your slurry.

- What is the use of rotary vacuum pump? A Guide to Reliable Rough Vacuum for Labs & Industry