To effectively maintain a press machine, you must implement a structured program that combines daily operator checks, scheduled technical inspections, and a proactive component management strategy. This involves diligent lubrication, consistent cleaning, regular calibration, and rigorous verification of all safety systems. It is not a one-time task but a continuous process of care.

Effective press maintenance is not about following a simple checklist; it is a multi-layered strategy. The goal is to transition your operation from a reactive state of fixing what's broken to a proactive state of preventing failures before they occur, ensuring safety, quality, and uptime.

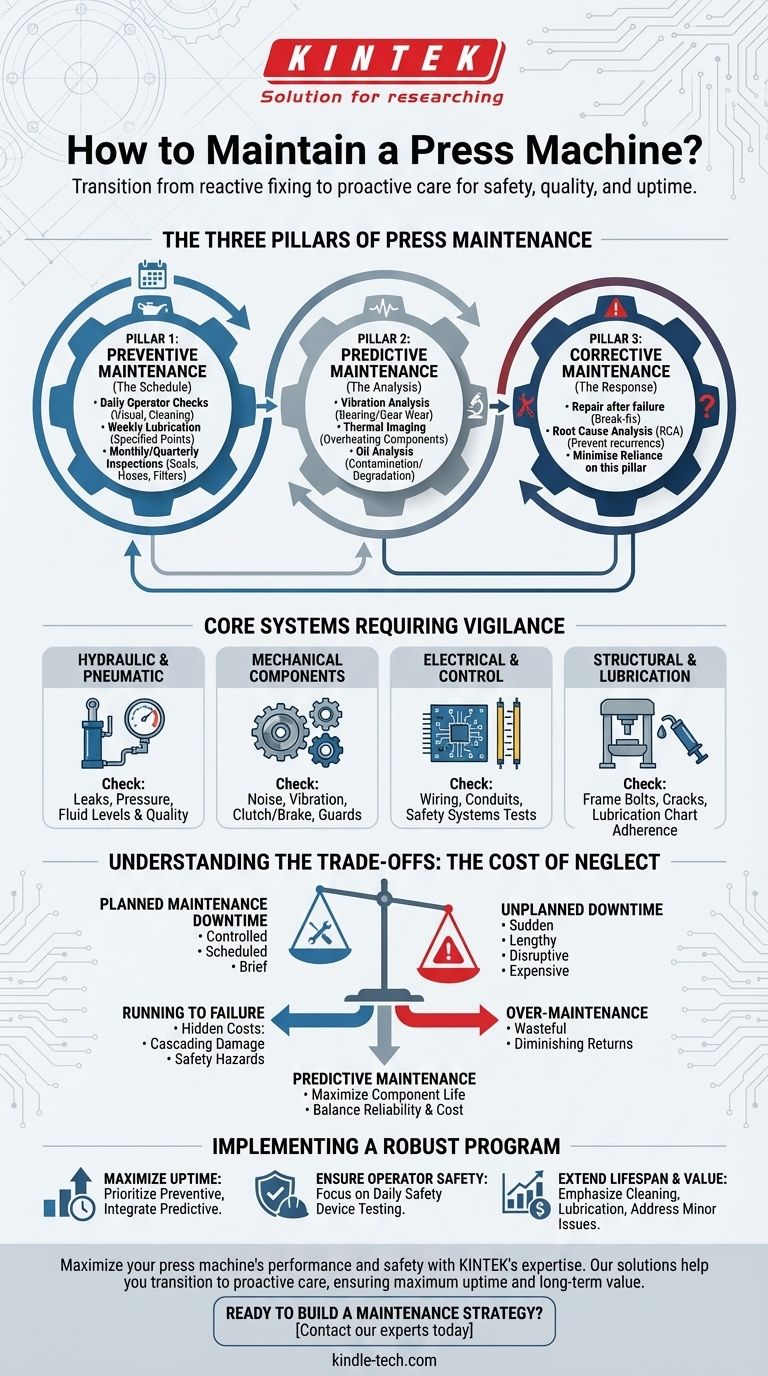

The Three Pillars of Press Maintenance

A comprehensive maintenance program is built on three distinct but interconnected approaches. Balancing them is key to a reliable operation.

Pillar 1: Preventive Maintenance (The Schedule)

This is your first and most critical line of defense against unplanned downtime. It consists of routine, time-based tasks performed to keep the machine in optimal condition.

Think of it as the machine's regular health check-up. These actions are scheduled regardless of the machine's apparent condition.

Key activities include daily operator checklists (visual inspections, cleaning), weekly lubrication of all specified points, and monthly or quarterly inspections of critical wear items like seals, hoses, and filters.

Pillar 2: Predictive Maintenance (The Analysis)

This advanced approach uses condition-monitoring technology to predict when a component might fail. Instead of replacing parts on a fixed schedule, you replace them based on data.

This moves beyond simple inspection to data-driven decision-making. It helps you catch developing problems that aren't yet visible to the naked eye.

Common techniques include vibration analysis to detect bearing or gear wear, thermal imaging to spot overheating electrical or hydraulic components, and oil analysis to check for fluid contamination or degradation.

Pillar 3: Corrective Maintenance (The Response)

This is the "break-fix" model, where maintenance is performed only after a component has failed. While unavoidable at times, an over-reliance on corrective maintenance is a sign of a poor overall strategy.

The goal of a good program is to minimize the need for corrective maintenance. When it is necessary, the focus should be on a rapid and effective repair.

Crucially, every corrective action should trigger a Root Cause Analysis (RCA). You must ask why the failure occurred to prevent it from happening again.

Core Systems Requiring Vigilance

A press is a complex machine. Focus your maintenance efforts on these critical systems where failures are most common and have the greatest impact.

Hydraulic and Pneumatic Systems

These systems are the muscle of the press. Leaks or pressure drops directly impact performance and safety.

Regularly check for fluid leaks around fittings, hoses, and cylinders. Monitor system pressure gauges to ensure they are within the specified operating range, and check fluid levels and quality in reservoirs.

Mechanical Components (Clutch, Brake, Flywheel)

These components manage the immense forces of the press stroke. Their failure can be catastrophic.

Listen for unusual noises and feel for excessive vibration during operation. Regularly inspect the clutch and brake for wear and proper engagement, and ensure all guards are securely in place.

Electrical and Control Systems

The nervous system of the press must be flawless for both function and safety.

Visually inspect wiring and conduits for damage or fraying. Most importantly, conduct frequent, documented tests of all safety systems, including emergency stops, light curtains, and two-hand controls.

Structural Integrity and Lubrication

The frame and lubrication network are the skeleton and circulatory system of the machine. Neglecting them leads to premature, widespread wear.

Periodically check the torque on critical frame bolts and inspect for any signs of cracks in welds or castings. Follow the manufacturer's lubrication chart precisely, using the correct type and amount of grease or oil.

Understanding the Trade-offs: The Cost of Neglect

Implementing a maintenance program requires an investment of time and resources. However, this investment must be weighed against the significant costs of inaction.

Production Downtime vs. Maintenance Time

The most common objection to maintenance is the need to stop production.

However, planned maintenance downtime is controlled, scheduled, and brief. Unplanned downtime from a failure is sudden, often lengthy, and far more disruptive and expensive.

The Hidden Costs of "Running to Failure"

Only fixing things when they break may seem cheaper in the short term, but it carries immense hidden costs.

A minor component failure can cause a cascading failure that damages more expensive parts of the machine. More importantly, a degraded machine poses a significant safety hazard to operators.

Over-Maintenance: A Point of Diminishing Returns

It is possible to perform too much maintenance. Replacing components that are still in good condition is wasteful.

This is where predictive maintenance provides its greatest value. It allows you to maximize the life of each component without risking an unexpected failure, striking the perfect balance between reliability and cost.

Implementing a Robust Maintenance Program

Your specific approach will depend on your production demands, risk tolerance, and the age of your equipment.

- If your primary focus is maximizing uptime: Prioritize a strong preventive schedule and begin integrating predictive technologies like oil and vibration analysis.

- If your primary focus is ensuring operator safety: Your program must center on daily, documented testing of all safety devices and regular inspection of structural and critical mechanical components.

- If your primary focus is extending machine lifespan and long-term value: Emphasize meticulous cleaning, religious adherence to the lubrication schedule, and addressing even minor issues immediately.

A well-maintained press is not a cost center; it is the engine of reliable and profitable production.

Summary Table:

| Maintenance Pillar | Key Activities | Primary Goal |

|---|---|---|

| Preventive (Schedule) | Daily operator checks, lubrication, inspections | Prevent failures before they occur |

| Predictive (Analysis) | Vibration analysis, thermal imaging, oil analysis | Predict failures using data to schedule repairs |

| Corrective (Response) | Repair after failure, Root Cause Analysis (RCA) | Fix issues and prevent recurrence |

Maximize your press machine's performance and safety with KINTEK's expertise.

A well-maintained press is the engine of your production line. KINTEK specializes in providing the lab equipment, consumables, and technical support necessary to implement a robust maintenance program tailored to your laboratory's specific needs. Our solutions help you transition from reactive fixes to proactive care, ensuring maximum uptime, operator safety, and long-term equipment value.

Ready to build a maintenance strategy that protects your investment? Contact our experts today for a personalized consultation.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- Can you use a hydraulic press for forging? Power, Precision, and Deep Deformation

- How fast is a hydraulic press? Understand the Critical Speed vs. Force Trade-off

- Why is a laboratory hydraulic press necessary for bio-electrochemical sensor electrodes? Enhance Signal Sensitivity

- How does a laboratory high-pressure hydraulic press influence B4C ceramic preforms? Optimize Your Ceramic Skeleton

- When was hydraulic press invented? Joseph Bramah's 1795 Revolution in Force Multiplication

- How is high temperature controlled in the hydraulic system? Prevent Damage and Boost Efficiency

- What are the factors that affect pellet quality? Master KBr Pellet Prep for Flawless FTIR Results

- What is the specific application of a laboratory hydraulic press in LNMO cathode fabrication? Enhance Density & Performance