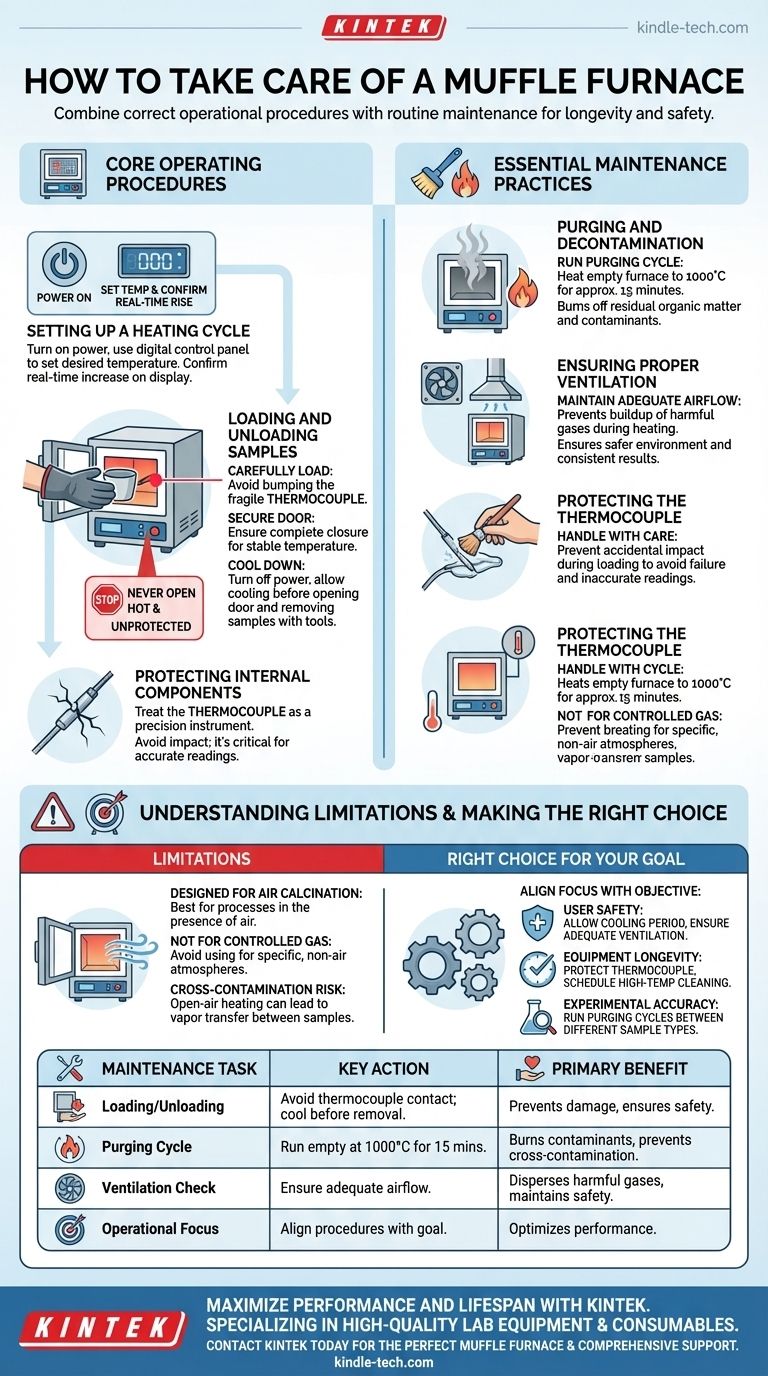

To properly care for a muffle furnace, you must combine correct operational procedures with routine maintenance. This involves carefully loading samples to protect internal components like the thermocouple, setting temperatures using the control panel, ensuring the door is securely closed during operation, and allowing samples to cool before removal. Regular cleaning cycles are also essential to prevent contamination and ensure reliable performance.

The key to muffle furnace longevity and safety is to treat it as a precision instrument, not just a simple oven. Proactive care during operation and consistent cleaning are far more effective than reactive repairs.

Core Operating Procedures

Proper operation is the first line of defense in maintaining your furnace. Following a consistent and careful procedure for every use prevents both immediate accidents and long-term wear.

Setting Up a Heating Cycle

Before placing anything inside, turn on the power and use the digital control panel to set your desired working temperature.

You can confirm the system is operating correctly by observing the control panel's display, which should show the real-time temperature gradually increasing toward your set point.

Loading and Unloading Samples

Always open the furnace door and carefully place items inside, taking extreme care to avoid bumping or disturbing the thermocouple, which is the sensitive temperature sensor typically located at the back.

Once the furnace is loaded, ensure the door is closed completely to maintain a stable internal temperature.

After the heating cycle is complete, turn off the power. For safety, allow the sample and the furnace chamber to cool significantly before opening the door and using appropriate tools to remove your items, preventing burns.

Essential Maintenance Practices

Routine maintenance extends the life of your furnace, ensures its accuracy, and prevents unexpected failures that could ruin an experiment or create a safety hazard.

Purging and Decontamination

Contaminants from samples can accumulate inside the furnace over time. An effective and economical way to clean the muffle is to run a purging cycle.

To do this, run the empty furnace up to 1000°C and hold it at that temperature for approximately 15 minutes. This helps burn off residual organic matter and other contaminants.

Ensuring Proper Ventilation

Pay close attention to the furnace atmosphere. Proper ventilation is critical to prevent the buildup of harmful gases that may be released from your samples during heating.

Adequate airflow ensures a safer working environment and can contribute to more consistent heating results.

Protecting Internal Components

The thermocouple is the most critical and fragile component inside the furnace. Accidental impact during loading is a common cause of failure, leading to inaccurate temperature readings and costly repairs. Treat it with care.

Understanding the Limitations

A muffle furnace is a powerful tool, but understanding its designed purpose is crucial for proper use and care.

Atmosphere Control

A standard muffle furnace is designed for heating processes in the presence of air, such as air calcination. It is a cost-effective choice for general heating.

These furnaces are not typically designed for processes that require a controlled gas passage or a specific, non-air atmosphere. Attempting to use them for such applications can lead to poor results and potential equipment damage.

Risk of Cross-Contamination

Because muffle furnaces heat samples in an open-air chamber, there is a risk of vapors from one sample contaminating subsequent batches.

This is why performing regular purging cycles, especially when switching between different types of materials, is a critical step for ensuring experimental accuracy.

Making the Right Choice for Your Goal

Your maintenance and operational focus should align with your primary objective.

- If your primary focus is user safety: Always allow for a cooling period before handling samples and ensure your lab space has adequate ventilation to disperse any off-gassing.

- If your primary focus is equipment longevity: Make it a rule to never touch the thermocouple and to perform a high-temperature cleaning cycle on a regular schedule.

- If your primary focus is experimental accuracy: Run a purging cycle between heating different types of samples to prevent cross-contamination from affecting your results.

By integrating these careful procedures and maintenance habits, you will ensure your muffle furnace remains a safe, reliable, and accurate instrument for years to come.

Summary Table:

| Maintenance Task | Key Action | Primary Benefit |

|---|---|---|

| Loading/Unloading | Avoid thermocouple contact; allow cooling before removal. | Prevents damage and ensures user safety. |

| Purging Cycle | Run empty at 1000°C for 15 minutes. | Burns off contaminants, prevents cross-contamination. |

| Ventilation Check | Ensure adequate airflow during operation. | Disperses harmful gases, maintains a safe environment. |

| Operational Focus | Align procedures with your primary goal (safety, longevity, accuracy). | Optimizes furnace performance for specific needs. |

Maximize the performance and lifespan of your laboratory equipment with KINTEK.

Proper maintenance is key to reliable results. KINTEK specializes in high-quality lab equipment and consumables, providing the durable tools and expert support your laboratory needs to operate safely and efficiently.

Contact KINTEK today to find the perfect muffle furnace for your application and learn more about our comprehensive support services.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the design and construction of a muffle furnace? A Guide to Its Isolated Heating Chamber

- What is the importance of muffle furnace? Ensuring Contaminant-Free Heating for Accurate Results

- What is a muffle furnace in the food industry? A Key Tool for Accurate Nutritional Analysis

- What precautions should you take while using a muffle furnace? Ensure Safe High-Temperature Processing in Your Lab

- What are the 3 official methods in determining ash and water content? A Guide to Proximate Analysis