To use a muffle furnace in a laboratory, you must first ensure the unit is safely installed and that you are wearing appropriate personal protective equipment (PPE). The process involves placing your sample centrally within the furnace's chamber, programming the required temperature and duration on the digital controller, and allowing the furnace to run its cycle. A critical final step is to let the furnace cool down completely before safely retrieving your sample.

The core principle of using a muffle furnace is not just heating a sample, but managing extreme thermal energy with precision and safety. Effective operation requires understanding that the furnace is a closed system where proper sample placement and controlled heating and cooling cycles are essential for accurate results and equipment longevity.

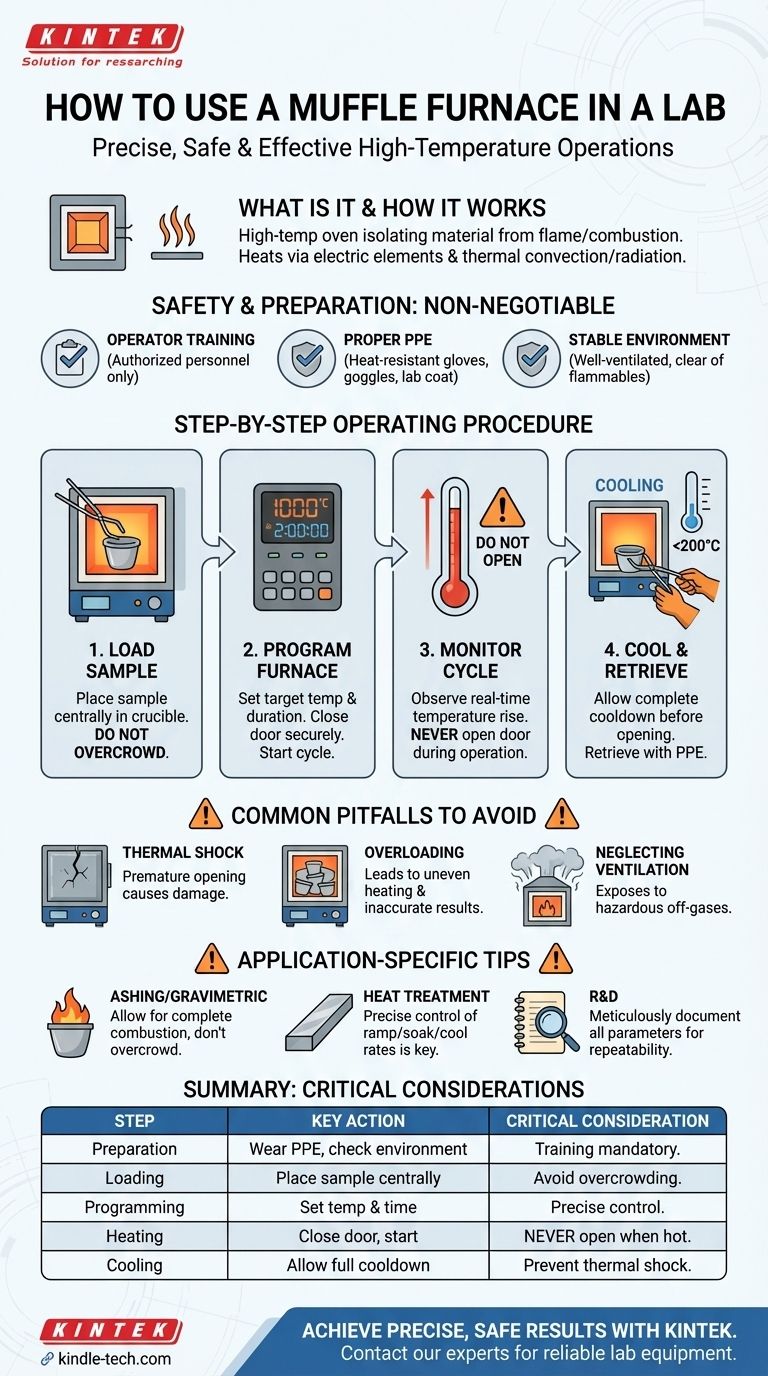

What is a Muffle Furnace and How Does It Work?

A muffle furnace, sometimes called a retort furnace, is a high-temperature oven designed to isolate the material being heated from the direct flames or by-products of combustion.

The Core Components

The furnace is built around four key parts: an insulated outer chamber for safety, a robust inner chamber (the muffle) typically made of ceramic, high-grade insulation to prevent heat loss, and a digital controller to manage the process.

The Heating Principle

The system works by using electric heating elements to heat the air inside the sealed muffle. This heat is then transferred to your sample through the principles of thermal convection (hot air circulation) and thermal radiation, ensuring uniform heating without direct contact with the heating elements.

Safety and Preparation: The Non-Negotiable First Steps

Proper preparation is not optional; it is fundamental to safe and effective operation. Mishandling a device that reaches over 1000°C can have severe consequences.

Operator Training

Only personnel who have received specific training and have permission from management should operate a muffle furnace. You must be fully familiar with your specific model's operating procedures and safety warnings.

Personal Protective Equipment (PPE)

Always wear appropriate PPE before operating the furnace. This typically includes heat-resistant gloves, safety goggles or a face shield, and a lab coat.

Proper Placement and Environment

The furnace must be placed on a stable, level workbench in a well-ventilated area. The space around it should be clear of flammable materials to prevent fire risk and allow for heat dissipation.

Step-by-Step Operating Procedure

Once all safety checks are complete, you can proceed with the operational steps.

1. Sample Preparation and Placement

Place your experimental items, often in a ceramic crucible, in the center of the furnace chamber. Do not overcrowd the furnace, as this will obstruct the circulation of hot air and lead to uneven heating and inaccurate results.

2. Programming the Furnace

Set the target temperature and any required heating ramp rates or hold times using the digital controller. Once the program is set, close the furnace door securely and turn on the main power.

3. Monitoring the Cycle

The control panel will typically display the set temperature and the real-time temperature inside the chamber. As the furnace heats up, you will see the real-time temperature rise to meet your setpoint, which indicates the system is operating correctly. Do not open the door during operation.

4. Cooldown and Sample Retrieval

After the heating cycle is complete, the furnace must be allowed to cool down. Never open the furnace door while it is at a high temperature. Rapid cooling can create thermal shock, potentially cracking the ceramic muffle or shattering your sample. Wait until the temperature has fallen to a safe level (often below 200°C, but consult your lab's protocol) before opening the door and retrieving your sample with tongs and heat-resistant gloves.

Common Pitfalls to Avoid

Understanding potential mistakes is as important as knowing the correct procedure.

Thermal Shock Damage

Opening the furnace door prematurely is the most common cause of damage. The rapid influx of cool air can crack the expensive ceramic muffle, leading to costly repairs and downtime.

Inaccurate Results from Overloading

Placing too many samples in the furnace or placing them too close to the walls prevents uniform heat distribution. This can lead to incomplete combustion in ashing applications or inconsistent properties in heat treatment.

Neglecting Ventilation

Many high-temperature processes, especially ashing organic materials, release fumes and off-gases. Operating the furnace in a poorly ventilated area or without a proper exhaust hood can expose operators to hazardous fumes.

Making the Right Choice for Your Goal

Your specific application dictates which operational parameters are most critical.

- If your primary focus is ashing or gravimetric analysis: Ensure the sample is not overcrowded to allow for complete combustion and accurate measurement of the remaining inorganic material.

- If your primary focus is heat treating metals or ceramics: Precise control over the temperature ramp rate, soak time, and cooling rate is paramount for achieving the desired material properties.

- If your primary focus is research and development: Meticulously document every parameter—from sample placement to the full temperature profile—to ensure your results are repeatable.

Mastering the muffle furnace is about applying controlled energy with a deep respect for safety and procedure.

Summary Table:

| Step | Key Action | Critical Consideration |

|---|---|---|

| 1. Preparation | Wear heat-resistant gloves and safety goggles. Ensure the furnace is on a stable surface in a ventilated area. | Operator training is mandatory. Never operate without proper PPE. |

| 2. Loading | Place the sample in a crucible at the center of the chamber. | Avoid overcrowding to ensure uniform heating and accurate results. |

| 3. Programming | Set the target temperature and time on the digital controller. | Precise control is key for applications like heat treatment. |

| 4. Heating | Close the door securely and start the cycle. Monitor the temperature display. | Never open the door during operation. |

| 5. Cooling & Retrieval | Allow the furnace to cool completely (often below 200°C) before opening. | Opening the door while hot causes thermal shock, damaging the furnace and sample. |

Achieve precise, safe, and repeatable high-temperature results in your laboratory.

Whether your application is ashing, heat treatment, or advanced research, the correct equipment and expert support are essential for success. KINTEK specializes in providing reliable lab equipment, including muffle furnaces, and the consumables you need to operate them effectively.

Let our experts help you enhance your lab's capabilities and ensure operator safety. Contact KINTEK today to discuss your specific requirements and find the perfect solution for your laboratory needs.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the mechanism of a muffle furnace? Master Precise, Contaminant-Free Heating

- What is the heating element of a muffle furnace? The Engine for High-Temp Precision

- What happens in the muffle furnace? Achieve Pure, Uniform High-Temperature Processing

- What type of furnace is a muffle furnace? A Guide to High-Purity, Contamination-Free Heating

- What is the meaning of muffle furnace? The Key to Pure, High-Temperature Processing