At its core, a continuous furnace is an industrial heating system designed to process materials in an uninterrupted flow. Unlike a batch furnace, which processes a finite load of material in a static chamber, a continuous furnace operates like a thermal assembly line. Material constantly enters one end, moves through precisely controlled heating and cooling zones, and exits the other, ready for the next stage of manufacturing.

A continuous furnace is not just a heating device; it is a complete thermal processing system engineered for high-volume production. Its fundamental advantage lies in moving a product through a sequence of optimized temperature zones, replacing the start-stop nature of batch processing with an efficient, uninterrupted flow.

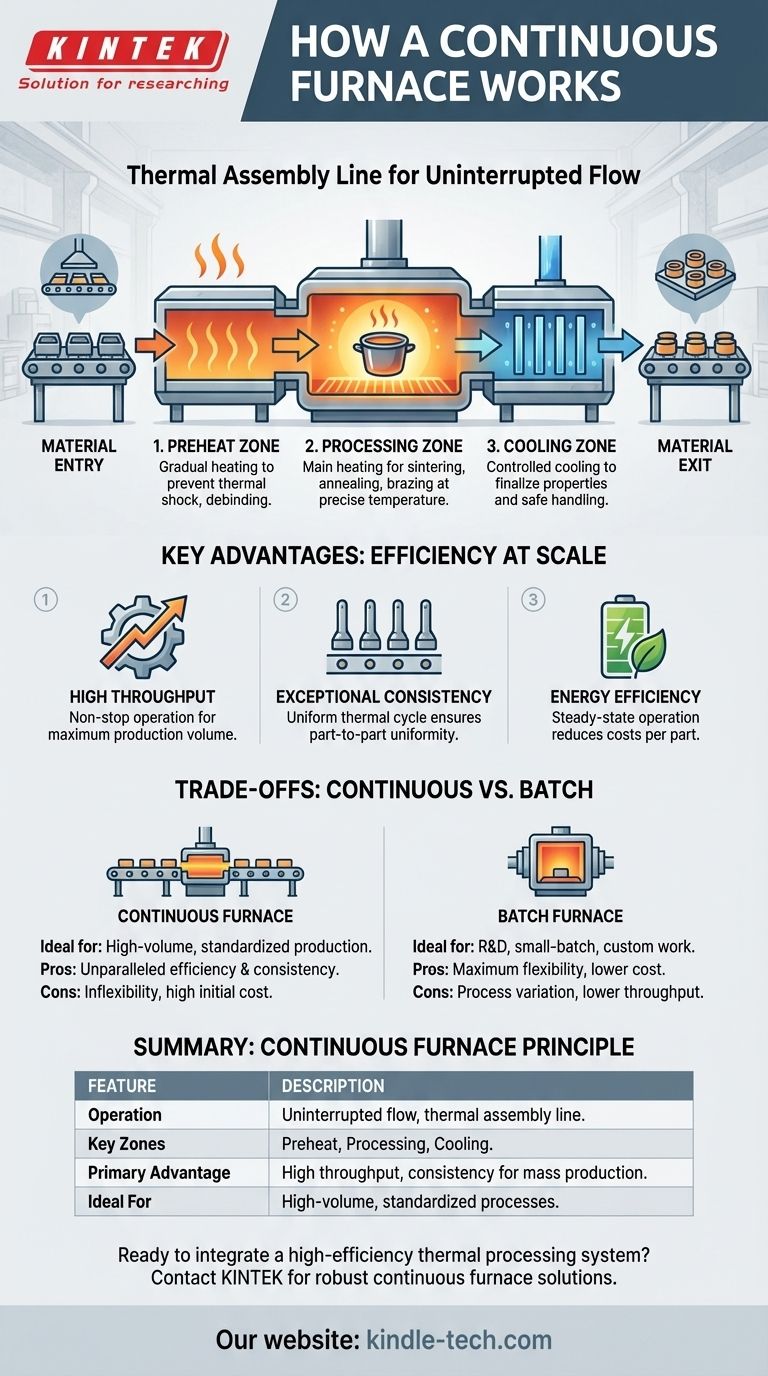

The Anatomy of a Continuous Process

The defining feature of a continuous furnace is its zoned architecture. A product moves sequentially through different environments within a single, integrated piece of equipment, ensuring each part experiences the exact same thermal profile.

The Three Critical Zones

A typical continuous furnace is divided into distinct sections, each with multi-zone temperature control.

-

Preheat Zone: As material enters the furnace, this first section gradually raises its temperature. This prevents thermal shock and can also be used for processes like debinding, where binding agents are safely burned off before high-temperature processing.

-

Processing Zone: This is the main heating section where the primary thermal process, such as sintering, annealing, or brazing, occurs. It is held at a precise, stable temperature to ensure the material achieves its desired metallurgical or chemical properties.

-

Cooling Zone: After leaving the hot zone, the material moves through a cooling section. The cooling rate is carefully controlled to finalize the material's properties and bring it down to a safe handling temperature before it exits the furnace.

The Transport Mechanism

The method of moving material through the furnace is critical to its design and function.

A common design is the pusher furnace, where products are loaded onto "boats" or trays. A mechanism pushes the train of boats through the furnace, with a new boat being added at the entrance as a finished one is removed at the exit.

Another type is the rotary furnace, where a slowly rotating tube transports loose material (like minerals or powders) down its length, mixing and heating it simultaneously.

Precise Atmosphere Control

Many modern processes cannot be performed in ambient air due to the risk of oxidation or contamination.

Continuous furnaces integrate sophisticated gas systems to maintain a specific processing atmosphere. This can be a vacuum to remove all reactive gases, or an inert atmosphere created by pumping in gases like nitrogen or argon to protect the material.

How Continuous Operation Achieves Superior Results

The shift from batch to continuous processing is driven by the need for efficiency and quality at scale.

Unmatched Throughput

Because the furnace operates non-stop, its throughput—the amount of product processed per unit of time—is exceptionally high. The "push rate" or transport speed can be varied to match upstream and downstream production needs, making it ideal for integration into a larger manufacturing line.

Exceptional Consistency

Every part that travels through a continuous furnace follows the exact same path and experiences the identical thermal cycle. This eliminates the process variations often seen between different batches in a batch furnace, leading to superior part-to-part and lot-to-lot consistency.

Energy Efficiency

While a continuous furnace has a high energy draw to reach its operating temperature, it maintains that temperature in a steady state. This is far more energy-efficient than the repeated cycles of heating and cooling required by a batch furnace, resulting in lower operational costs per part at high volumes.

Understanding the Trade-offs: Continuous vs. Batch

Despite its advantages, a continuous furnace is not a universal solution. The choice between continuous and batch processing involves significant trade-offs.

The Constraint of Inflexibility

A continuous furnace is optimized for a single, stable process. Changing the temperature profile is a major undertaking that requires slowly adjusting multiple zones and can halt production for hours or days. In contrast, a batch furnace (like a simple lab or muffle furnace) offers maximum flexibility for running different thermal cycles for R&D or varied product lines.

High Initial Investment

These are large, complex, and expensive systems. The capital cost is significantly higher than for a batch furnace of equivalent processing capability. This investment is only justifiable with sufficient production volume.

Dependence on Process Stability

The entire system's efficiency relies on a constant and stable flow of material. Any interruption in the supply chain or malfunction in a single zone can bring the entire production line to a halt, creating a significant operational risk.

Making the Right Choice for Your Process

The decision to use a continuous furnace must be aligned with your specific production goals.

- If your primary focus is high-volume, standardized production: A continuous furnace offers unparalleled efficiency, throughput, and product consistency once established.

- If your primary focus is research, development, or small-batch custom work: The flexibility, lower cost, and quick changeover capabilities of a batch furnace are the superior choice.

- If your primary focus is preventing material oxidation: The key factor is atmosphere control (e.g., a vacuum or inert gas), a feature that can be engineered into both continuous and batch furnace designs.

Ultimately, selecting the right furnace depends on a clear-eyed assessment of your production volume, process variability, and long-term operational goals.

Summary Table:

| Feature | Description |

|---|---|

| Operation Principle | Uninterrupted material flow through distinct heating and cooling zones. |

| Key Zones | Preheat, Processing (e.g., sintering), and Controlled Cooling. |

| Primary Advantage | High throughput and exceptional part-to-part consistency for mass production. |

| Ideal For | High-volume, standardized processes requiring a stable thermal profile. |

Ready to integrate a high-efficiency thermal processing system into your production line?

KINTEK specializes in advanced lab equipment and consumables, providing robust continuous furnace solutions tailored to your laboratory's high-volume manufacturing needs. Our expertise ensures you achieve unparalleled throughput and product consistency.

Contact us today to discuss how our continuous furnaces can enhance your efficiency and quality. Let's build your thermal assembly line together.

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Mesh belt controlled atmosphere furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- What are the equipment requirements for loading platinum (Pt) onto composite supports? Precise Stirring for High Dispersion

- What is the difference between pyrolysis combustion and gasification? A Guide to Thermal Conversion Technologies

- How do high-temperature reaction furnaces control in-situ MMCs? Master Material Precision and Structural Integrity

- What is the range of pyrolysis? Master Temperature Control for Optimal Bio-Product Yields

- How is a high-temperature calcination furnace utilized in BZY20 Sol-gel? Achieve Pure Cubic Perovskite Phases