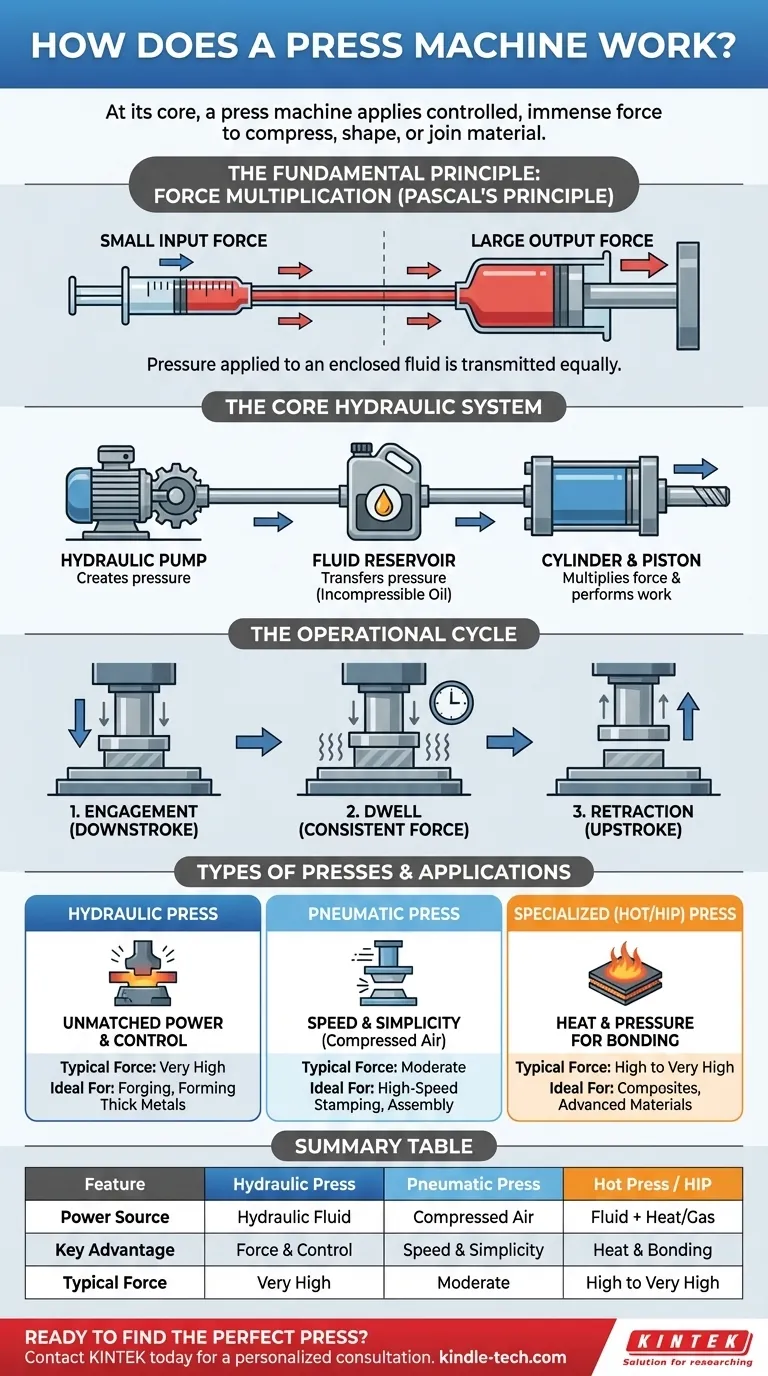

At its core, a press machine works by using a power source to generate and apply a controlled, immense force to a specific area. This force, typically created by a hydraulic or pneumatic system, is transmitted through a ram or plate to compress, shape, join, or stamp a material placed on a stationary bed.

The true principle behind most industrial presses is not just the application of force, but the multiplication of force. By using an incompressible fluid, a small, manageable input force can be converted into an exceptionally large output force, enabling the shaping and forming of even the most robust materials.

The Fundamental Principle: Force Multiplication

The ability of a press to generate tonnage far beyond its mechanical input is based on a foundational principle of fluid dynamics. This is the key to understanding how these powerful machines operate.

Introducing Pascal's Principle

The workhorse behind the hydraulic press is Pascal's Principle. This states that pressure applied to an enclosed, incompressible fluid is transmitted equally and undiminished to every portion of the fluid and the walls of the containing vessel.

Imagine two connected syringes, one small and one large. Pushing the plunger on the small syringe with a small amount of force creates pressure in the fluid. This same pressure acts on the entire surface of the large plunger, generating a much larger output force.

This is exactly how a hydraulic press multiplies force. A small force applied by a pump to the hydraulic fluid results in a massive force exerted by the main pressing cylinder.

The Core Hydraulic System

A typical hydraulic press translates this principle into action using three key components:

- The Hydraulic Pump: This is the motor that applies the initial pressure to the hydraulic fluid (usually oil). It creates the "small force" in our syringe analogy.

- The Fluid: The oil acts as the medium for transferring pressure. Because it is virtually incompressible, it efficiently moves the force from the pump to the cylinder without loss.

- The Cylinder and Piston: This is the large "output" syringe. The pressurized fluid pushes against a large piston (also called a ram), which extends downward with immense, multiplied force to do the work.

The Operational Cycle of a Press

While the underlying principle is constant, the action of a press occurs in a clear, repeatable cycle controlled by the hydraulic system.

Engagement: The Downstroke

The cycle begins when the pump is engaged. It forces hydraulic fluid into the main cylinder, causing the piston and the attached ram to extend downwards towards the workpiece.

Dwell: Applying Consistent Force

Once the ram makes contact, the system maintains a set pressure for a specific duration, known as dwell time. This is critical for processes like curing adhesives, forming complex shapes, or ensuring a complete bond.

Retraction: The Upstroke

After the dwell time is complete, valves in the hydraulic system are reversed. The fluid pressure is released, and the piston retracts back to its starting position, allowing the finished part to be removed and a new workpiece to be loaded.

Understanding the Variations and Trade-offs

Not all presses are the same. The specific power source and added features are chosen based on the required force, speed, and application.

Hydraulic Presses: Unmatched Power and Control

This is the most common type for high-force applications. They offer incredible force generation and precise control over pressure and speed. Their primary trade-off is that they are generally slower than other types and require maintenance to prevent oil leaks.

Pneumatic Presses: Speed and Simplicity

These presses use compressed air instead of oil. Because air is compressible, they cannot generate the extreme forces of a hydraulic press. However, they are exceptionally fast, clean, and mechanically simpler, making them ideal for high-speed stamping, punching, and assembly of smaller components.

Specialized Presses: Adding Heat and Complexity

Many industrial processes require more than just force.

- Hot Presses integrate heating elements into the platens to cure glues, laminate materials, or bond composites.

- Hot Isostatic Presses (HIP) take this a step further, applying both high heat and uniform gas pressure from all directions inside a sealed chamber. This is used to create dense, flawless parts from metal powders or advanced ceramics.

Making the Right Choice for Your Goal

The right press is always determined by the job it needs to perform. The decision hinges on the required force, cycle speed, and the nature of the material itself.

- If your primary focus is maximum force for forging or forming thick metal: A hydraulic press is the only choice due to its unparalleled power.

- If your primary focus is high-speed repetition for stamping or light assembly: A pneumatic press offers the speed and simplicity needed for high-volume production.

- If your primary focus is bonding composites or creating advanced materials: A specialized hot press or hot isostatic press is necessary to apply both force and thermal energy.

By understanding the principle of force multiplication, you can now see any press not as a brute-force machine, but as a precise instrument of industrial power.

Summary Table:

| Feature | Hydraulic Press | Pneumatic Press | Hot Press / HIP |

|---|---|---|---|

| Power Source | Hydraulic Fluid (Oil) | Compressed Air | Hydraulic Fluid + Heat / Gas Pressure |

| Key Advantage | Unmatched Force & Control | High Speed & Simplicity | Heat & Pressure for Bonding/Curing |

| Typical Force | Very High | Moderate | High to Very High |

| Ideal For | Forging, Forming Thick Metals | High-Speed Stamping, Light Assembly | Composites, Advanced Materials, Laminates |

Ready to find the perfect press for your application?

Whether you need the immense force of a hydraulic press, the high speed of a pneumatic system, or the advanced capabilities of a hot press, KINTEK has the expertise and equipment to meet your laboratory and industrial needs. Our team can help you select the right press to enhance your production efficiency and material outcomes.

Contact KINTEL today for a personalized consultation and discover how our press solutions can power your success.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.