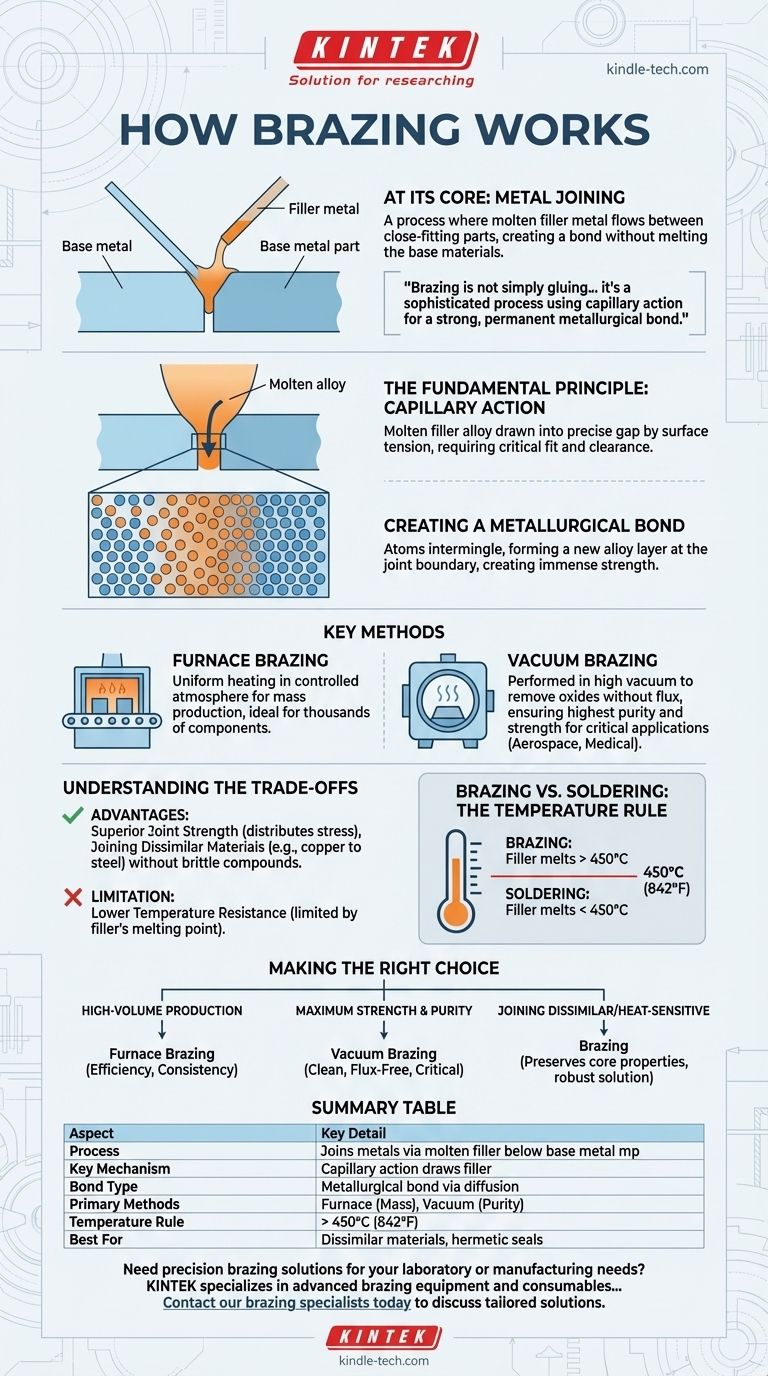

At its core, brazing is a metal-joining process where a filler metal is heated until it melts and flows between two or more close-fitting parts, creating a bond as it cools and solidifies. Critically, the temperature is high enough to melt the filler metal but is always kept below the melting point of the base materials being joined. This distinction is the defining characteristic of the process.

Brazing is not simply gluing with metal. It is a sophisticated process that uses capillary action to draw a molten filler alloy into a precisely fitted joint, forming a strong, permanent metallurgical bond upon cooling.

The Fundamental Principle: Capillary Action

The "magic" of brazing relies on a scientific principle to create exceptionally strong and clean joints. Understanding this is key to understanding the process.

How Capillary Action Works

Capillary action is the tendency of a liquid to be drawn into a narrow space, even against the force of gravity. In brazing, the precisely controlled, narrow gap between the two base materials acts as a capillary.

When the filler metal melts, surface tension pulls the liquid alloy into this gap, ensuring it completely fills the joint. This is why the fit and clearance between the parts are so critical to a successful braze.

Creating a Metallurgical Bond

Brazing creates more than just a physical connection. As the molten filler metal flows over the hot base materials, a small amount of diffusion occurs at the interface.

The atoms of the filler metal and the base metal intermingle, forming a new alloy layer at the joint boundary. This metallurgical bond is what gives a properly brazed joint its immense strength—often exceeding the strength of the filler metal itself.

Key Methods and Their Purpose

While the principle remains the same, the method of applying heat and controlling the environment changes based on the application's demands.

Furnace Brazing: For Scale and Efficiency

In furnace brazing, the entire assembly, with the filler metal pre-placed, is heated uniformly in a controlled-atmosphere furnace.

This method is ideal for mass production, as thousands of components can be brazed simultaneously. It ensures consistent heating and produces reliable joints at a large scale.

Vacuum Brazing: For Purity and Strength

Vacuum brazing is performed inside a high-vacuum chamber. The absence of air eliminates the need for chemical fluxes, which are typically used to prevent oxidation.

This fluxless process is exceptionally clean. The vacuum actively removes oxides and other contaminants from the metal surfaces, resulting in the highest possible joint strength and purity. It is the preferred method for critical applications in aerospace, medical, and high-performance electronics.

Understanding the Trade-offs

No process is perfect for every scenario. Acknowledging the advantages and limitations of brazing is essential for making an informed decision.

Advantage: Superior Joint Strength

Because brazing creates a metallurgical bond across the entire joint surface, it distributes stress evenly. The resulting joints are incredibly strong, ductile, and can create a permanent, hermetic seal.

Advantage: Joining Dissimilar Materials

Brazing is one of the most effective ways to join different types of metals, such as copper to steel or aluminum to ceramic. Since the base metals are not melted, it avoids the formation of brittle compounds that can occur during welding.

Limitation: Lower Temperature Resistance

The service temperature of a brazed component is limited by the melting point of the filler alloy used. It cannot be used in environments hotter than the filler's melting temperature.

Brazing vs. Soldering: The Temperature Rule

The distinction between brazing and soldering is defined by temperature. If the filler metal melts above 450°C (842°F), the process is considered brazing. If it melts below this temperature, it is soldering.

Making the Right Choice for Your Goal

Your application's requirements will determine the best approach.

- If your primary focus is high-volume production of standard components: Furnace brazing offers unmatched efficiency and consistency for creating thousands of joints at once.

- If your primary focus is maximum strength and purity for a critical component: Vacuum brazing is the superior choice, creating exceptionally clean, strong, and flux-free joints required for demanding industries.

- If your primary focus is joining dissimilar materials or heat-sensitive components: Brazing provides a robust solution by joining materials without melting them, preserving their core properties.

Understanding these principles allows you to leverage brazing not just as a joining method, but as a precise engineering solution.

Summary Table:

| Brazing Aspect | Key Detail |

|---|---|

| Process | Joins metals using molten filler alloy below base metal melting point |

| Key Mechanism | Capillary action draws filler into narrow joint gaps |

| Bond Type | Metallurgical bond through atomic diffusion |

| Primary Methods | Furnace brazing (mass production), Vacuum brazing (high purity) |

| Temperature Rule | Filler metal melts above 450°C (842°F) |

| Best For | Dissimilar materials, heat-sensitive components, hermetic seals |

Need precision brazing solutions for your laboratory or manufacturing needs? KINTEK specializes in advanced brazing equipment and consumables that deliver superior joint strength, purity, and reliability. Whether you require high-volume furnace brazing systems or high-purity vacuum brazing technology for critical applications, our expertise ensures optimal results for joining dissimilar materials and creating permanent metallurgical bonds. Contact our brazing specialists today to discuss how we can enhance your metal-joining processes with tailored solutions that meet your specific requirements.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing

- Where are vacuum furnaces used? Essential for High-Purity Heat Treatment in Critical Industries

- Does brazing require heat? Yes, it's the catalyst for creating strong, permanent bonds.

- What are the advantages of brazing over braze welding? Achieve Stronger, Cleaner, and Repeatable Joints