In short, annealing improves mechanical properties by using a precise cycle of heating and controlled cooling to fundamentally alter a metal's internal crystal structure. This process relieves internal stresses, refines the grain structure, and adjusts the density of atomic-level defects, allowing engineers to trade properties like hardness for increased ductility and toughness.

The term "improve" is entirely dependent on the application's goal. Annealing doesn’t make a material universally "better"; it tailors its properties for a specific purpose, most often by making a hard, brittle metal softer, more ductile, and easier to work with.

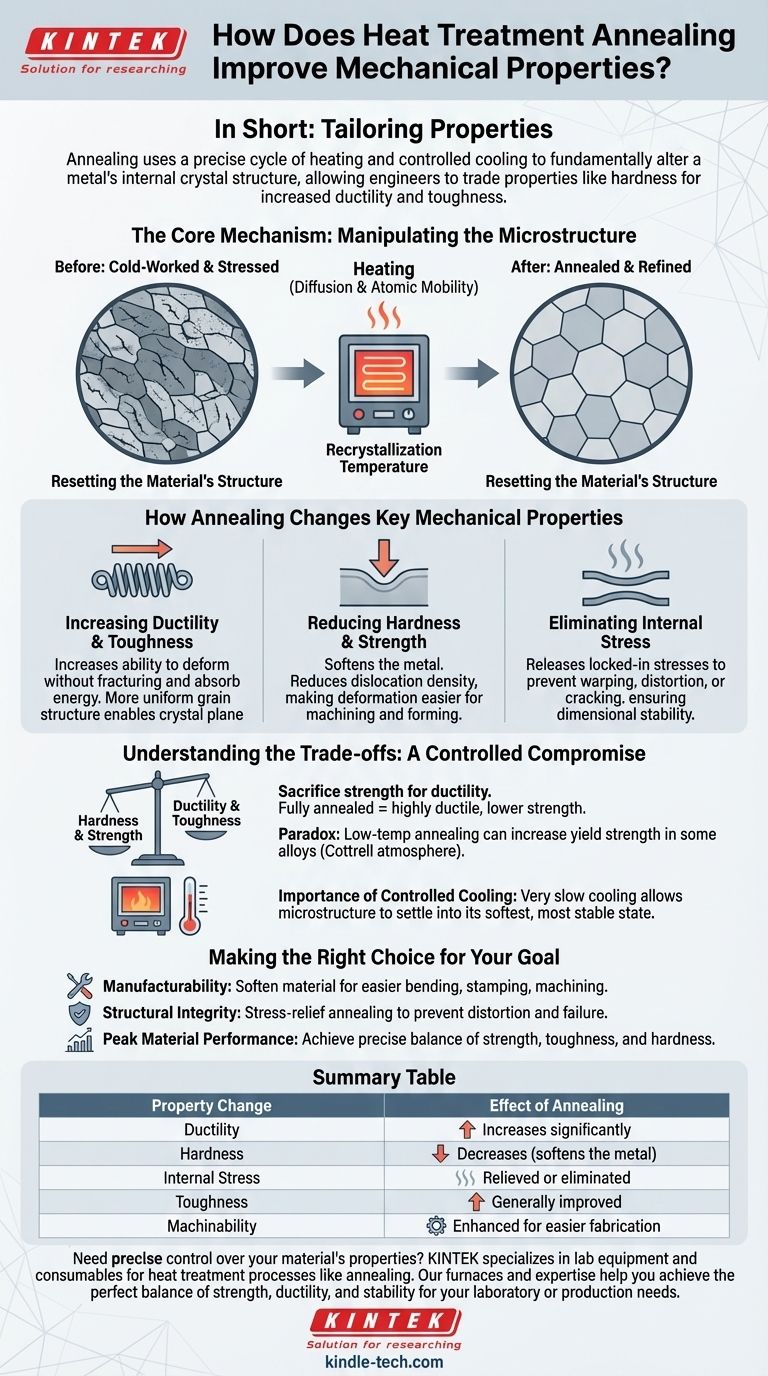

The Core Mechanism: Manipulating the Microstructure

To understand how annealing works, you must look inside the metal at its crystal structure, or microstructure. This internal architecture dictates its performance.

What is the Goal of Annealing?

When a metal is bent, stamped, or welded (a process known as cold working), its internal structure becomes stressed and distorted. This makes the metal harder but also more brittle.

The primary goal of annealing is to reverse these effects. It aims to increase ductility (the ability to deform without fracturing), relieve internal stresses, and refine the grain structure to create a more uniform and predictable material.

The Role of Heat and Diffusion

Heating a metal provides the thermal energy its atoms need to move, a process called diffusion. This atomic mobility is the engine of change.

As the metal is held at the annealing temperature, atoms can rearrange themselves into a more stable, lower-energy state, effectively healing the defects introduced during cold working.

Recrystallization: Resetting the Material's Structure

For a heavily cold-worked material, heating it above its recrystallization temperature triggers the formation of entirely new, strain-free crystals or "grains."

This process effectively erases the previous microstructure, replacing the distorted, stressed grains with a new set that is softer and more ductile.

How Annealing Changes Key Mechanical Properties

The changes to the microstructure translate directly into tangible changes in performance.

Increasing Ductility and Toughness

By creating a more uniform, stress-free grain structure, annealing allows the metal's internal crystal planes to slide past one another more easily. This dramatically increases its ability to bend, stretch, and absorb energy before fracturing.

Reducing Hardness and Strength

In most cases, especially with full annealing, the process softens the metal. Relieving stress and reducing the density of defects (dislocations) makes the material easier to deform.

This reduction in hardness and yield strength is often the desired outcome, making the metal easier to machine, form, or stamp in subsequent manufacturing steps.

Eliminating Internal Stress

Internal stresses from processes like welding or casting can cause a component to warp, distort, or even crack over time.

Annealing allows the microstructure to relax, releasing these locked-in stresses and ensuring the part remains dimensionally stable throughout its service life.

Understanding the Trade-offs

Annealing is not a magic bullet; it is a process of controlled compromise. Understanding the inherent trade-offs is critical for making sound engineering decisions.

The Hardness vs. Ductility Exchange

The most fundamental trade-off in annealing is between strength and ductility. You almost always sacrifice one to gain the other.

A fully annealed component will be highly ductile and easy to form but will have a lower tensile strength and hardness than its cold-worked counterpart.

When Annealing Can Increase Strength

Paradoxically, specific low-temperature annealing treatments can sometimes increase yield strength. This occurs in certain alloys, like some steels, after light cold working.

The heat allows carbon atoms to migrate to and lock dislocations in place, forming a "Cottrell atmosphere." This pinning action makes it harder to initiate movement (higher yield strength) but often reduces overall elongation.

The Importance of Controlled Cooling

The rate of cooling is just as important as the heating temperature. Cooling too quickly can introduce new stresses or create a different, harder microstructure.

True annealing almost always involves very slow cooling, often by leaving the part inside the insulated furnace as it cools down. This ensures the microstructure can settle into its softest, most stable state.

Making the Right Choice for Your Goal

The "improvement" you seek from annealing depends entirely on your end goal.

- If your primary focus is manufacturability: Annealing is used to soften the material, making it easier to bend, stamp, or machine without cracking.

- If your primary focus is structural integrity after fabrication: Stress-relief annealing is critical to prevent distortion and premature failure in welded or cast components.

- If your primary focus is peak material performance: You must see annealing as one step in a sequence of heat treatments designed to achieve a precise balance of strength, toughness, and hardness.

Ultimately, annealing provides control, allowing you to reset a material's properties to achieve a specific engineering outcome.

Summary Table:

| Property Change | Effect of Annealing |

|---|---|

| Ductility | Increases significantly |

| Hardness | Decreases (softens the metal) |

| Internal Stress | Relieved or eliminated |

| Toughness | Generally improved |

| Machinability | Enhanced for easier fabrication |

Need precise control over your material's properties? KINTEK specializes in lab equipment and consumables for heat treatment processes like annealing. Our furnaces and expertise help you achieve the perfect balance of strength, ductility, and stability for your laboratory or production needs. Contact us today to discuss your application!

Visual Guide

Related Products

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the role of a tube furnace in the thermal treatment of argyrodite electrolytes? Master Ionic Conductivity

- How does an industrial tube furnace ensure the required process conditions for supercritical fluid experimental devices?

- What happens when quartz is heated? A Guide to Its Critical Phase Transitions and Uses

- What role does a quartz tube furnace play in hBN synthesis? Optimize Your Chemical Vapor Deposition Results

- Why use quartz tubes and vacuum sealing for sulfide solid-state electrolytes? Ensure Purity & Stoichiometry