At its core, isostatic pressing is a manufacturing process that uses a fluid to apply perfectly uniform pressure to a powdered material from all directions. By enclosing the powder in a flexible mold and submerging it in a pressurized liquid or gas, the process compacts the material into a solid, highly dense shape without the limitations of traditional, one-directional pressing.

The critical insight is that isostatic pressing leverages a fundamental principle of fluid dynamics—that pressure in a fluid is exerted equally in all directions. This allows it to create complex parts with exceptionally consistent density and strength, something conventional pressing methods struggle to achieve.

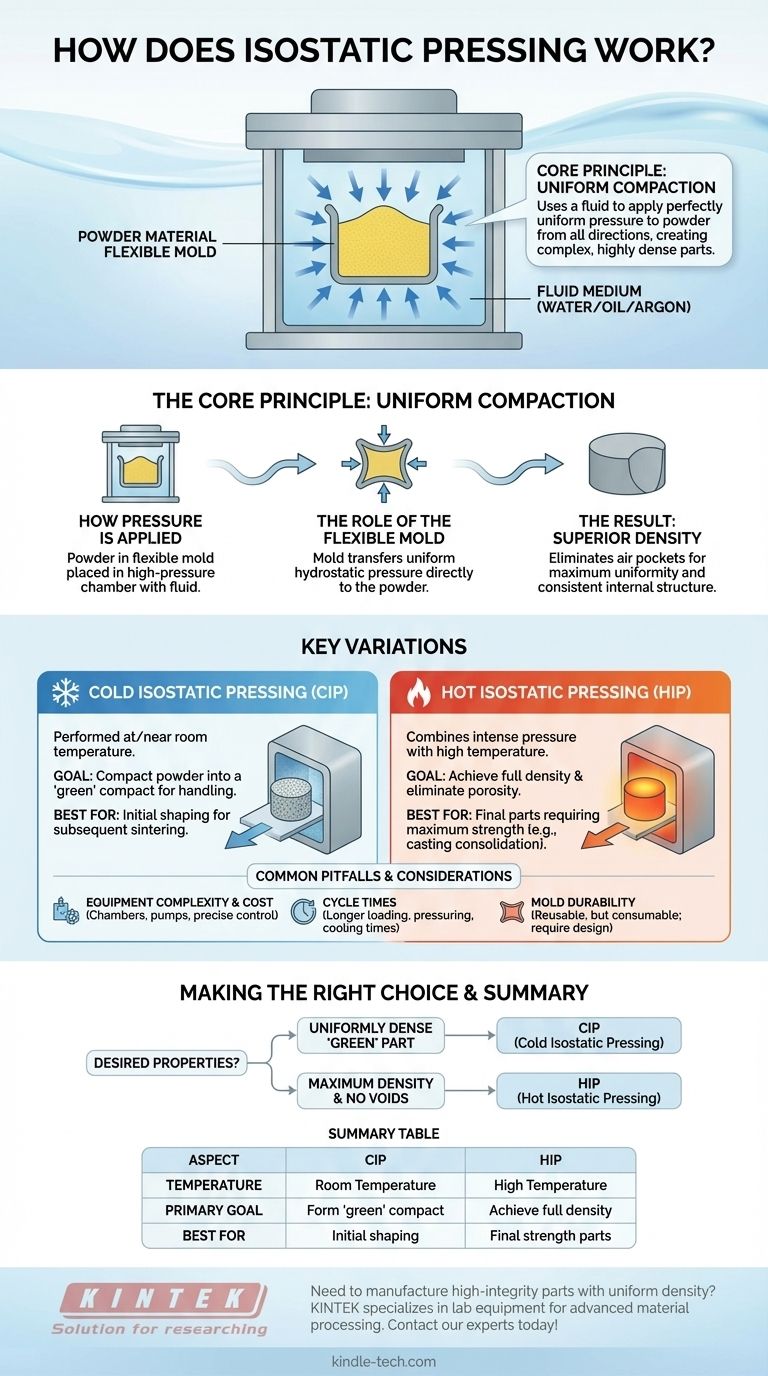

The Core Principle: Uniform Compaction

Isostatic pressing is fundamentally different from conventional methods that use a piston to apply force along a single axis. This unique, all-sides approach is what gives the process its key advantages.

How Pressure is Applied

The process begins by placing a powdered material, such as metal or ceramic, into a sealed, flexible container or mold made of rubber or plastic. This container is then placed inside a high-pressure chamber filled with a fluid medium, typically water, oil, or an inert gas like argon. When the chamber is pressurized, the fluid transmits that pressure evenly onto every surface of the flexible mold.

The Role of the Flexible Mold

The flexible mold is the key component that transfers the uniform hydrostatic pressure from the fluid directly to the powder inside. Because the pressure is equal everywhere on the mold's surface, the powder is compacted with the same force from every direction simultaneously.

The Result: Superior Density and Microstructure

This uniform compaction squeezes out air pockets and voids between the powder particles much more effectively than uniaxial pressing. The final result is a product with maximum uniformity of density and an internal structure that is consistent throughout the entire part, regardless of its shape or complexity.

Key Variations of the Process

The term "isostatic pressing" generally refers to two distinct but related techniques: Cold Isostatic Pressing (CIP) and Hot Isostatic Pressing (HIP).

Cold Isostatic Pressing (CIP)

CIP is performed at or near room temperature. Its main purpose is to compact powders into a solid form, often called a "green" compact. This initial part has good strength for handling but requires a subsequent heating process (sintering) to achieve its final, full-density properties.

Hot Isostatic Pressing (HIP)

HIP combines intense pressure with high temperatures, often in a chamber filled with inert argon gas. This process is used to consolidate powders into a fully dense final product in a single step or to eliminate any remaining internal porosity in parts made by other methods, like casting or 3D printing. The combination of heat and pressure enhances material properties significantly.

Common Pitfalls and Considerations

While powerful, isostatic pressing involves specific trade-offs that are important to understand.

Equipment Complexity and Cost

The need for high-pressure chambers, pumps, and, in the case of HIP, sophisticated heating and control systems, makes the equipment more complex and expensive than traditional mechanical presses. The process parameters—temperature, pressure, and time—must be monitored and controlled precisely by computers.

Cycle Times

The process of loading the chamber, pressurizing, holding, depressurizing, and cooling can result in longer cycle times compared to faster methods like die compaction. This makes it better suited for high-value components where material properties are the primary concern over mass production speed.

Mold Durability

The flexible molds are subjected to immense pressures and must be designed carefully. While reusable, they are consumable items that will eventually wear out and require replacement, adding to the operational cost of the process.

Making the Right Choice for Your Goal

Selecting the correct isostatic process depends entirely on the desired properties of the final component.

- If your primary focus is creating a uniformly dense "green" part for subsequent sintering: Cold Isostatic Pressing (CIP) is the most effective and economical choice.

- If your primary focus is achieving maximum density and eliminating all internal voids in a finished component: Hot Isostatic Pressing (HIP) is the necessary process to achieve superior mechanical properties.

Ultimately, isostatic pressing provides a powerful solution for manufacturing parts where internal integrity and uniform strength are paramount.

Summary Table:

| Aspect | Cold Isostatic Pressing (CIP) | Hot Isostatic Pressing (HIP) |

|---|---|---|

| Temperature | Room Temperature | High Temperature |

| Primary Goal | Form a 'green' compact for sintering | Achieve full density and eliminate porosity |

| Best For | Initial shaping with uniform density | Final parts requiring maximum strength |

Need to manufacture high-integrity parts with uniform density? KINTEK specializes in lab equipment and consumables for advanced material processing. Our expertise in isostatic pressing solutions can help you achieve superior material properties for your most demanding applications. Contact our experts today to discuss how we can support your laboratory's specific needs!

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

People Also Ask

- How is isostatic pressing distinguished from conventional pressing? Unlock Superior Uniformity and Density

- What products are made from cold isostatic pressing? Achieve Uniform Density in Complex Parts

- Why is a cold isostatic press preferred over a uniaxial press for tungsten powder? Achieve Uniform Powder Compaction

- What is the specific function of a cold isostatic press in the sintering process of LiFePO4? Maximize Battery Density

- Why is semi-isostatic pressing used for ceramics? Unlock Uniform Density and Superior Precision

- What is the pressing method in ceramics? A Guide to Shaping Dense, High-Performance Parts

- How much does an isostatic press cost? A Guide to Lab vs. Industrial Pricing

- How does a uniaxial cold press contribute to the preparation of sulfide solid electrolyte layers? Key to ASSB Density