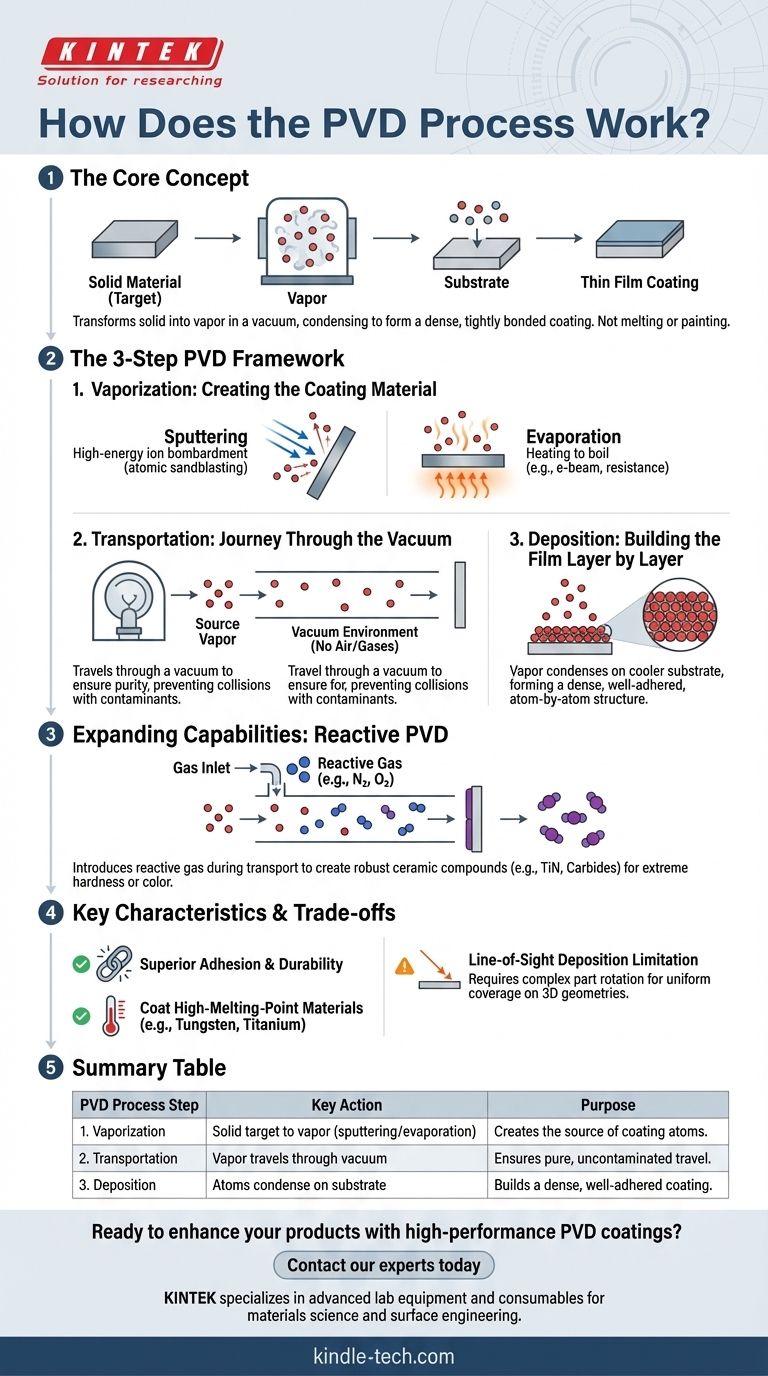

At its core, Physical Vapor Deposition (PVD) is a vacuum deposition method used to produce high-performance thin films and coatings. The process works by transforming a solid material into a vapor, transporting that vapor through a vacuum chamber, and allowing it to condense onto the surface of an object, or substrate, where it forms a thin, tightly bonded coating.

The fundamental principle of PVD is not about melting or painting, but about converting a solid material directly into a vapor of individual atoms or molecules inside a vacuum. This controlled environment is what enables the creation of exceptionally pure, dense, and durable coatings that are often impossible to achieve with other methods.

The PVD Process: A Three-Step Framework

Every PVD process, regardless of the specific technique used, follows the same fundamental sequence of events. Understanding these three steps is key to grasping how PVD achieves its unique results.

Step 1: Vaporization - Creating the Coating Material

The first step is to generate a vapor from the solid source material, known as the "target." This is not done with simple heat alone but with high-energy physical processes.

The two primary methods of vaporization are:

- Sputtering: The target is bombarded with high-energy ions from a gaseous plasma. Think of it as an atomic-scale sandblasting, where the impact of the ions dislodges atoms from the target, ejecting them into the vacuum chamber.

- Evaporation: The target material is heated in a vacuum using methods like an electron beam or simple resistance heating until it boils and releases a vapor of atoms or molecules.

Step 2: Transportation - The Journey Through the Vacuum

Once atoms are freed from the target, they travel through the vacuum chamber toward the substrate.

The vacuum environment is critical. By removing air and other gases, it ensures the vaporized atoms can travel from the source to the substrate without colliding with or reacting to unwanted particles. This preserves the purity of the coating.

Step 3: Deposition - Building the Film Layer by Layer

When the vaporized atoms reach the cooler surface of the substrate, they condense back into a solid state.

This condensation forms a thin film that grows atom by atom. Because the arriving atoms often have high kinetic energy, they can arrange themselves into a very dense and well-adhered structure, creating a strong bond with the substrate surface.

Expanding Capabilities with Reactive PVD

While the three-step process can deposit pure materials like metals, a common variation called Reactive PVD is used to create even more robust compound coatings.

How a Reactive Process Works

During the transportation step, a specific reactive gas—such as nitrogen, oxygen, or a carbon-containing gas—is intentionally introduced into the vacuum chamber.

Why It's Used: Creating Ceramic Coatings

The vaporized metal atoms react with this gas to form a new compound before or as they deposit on the substrate. For example, titanium vapor can react with nitrogen gas to form titanium nitride (TiN), an extremely hard, gold-colored ceramic.

This technique allows for the deposition of high-performance ceramic coatings like nitrides, carbides, and oxides from a simple metallic target, dramatically expanding the range of possible surface properties.

Understanding the Key Characteristics and Trade-offs

PVD is chosen for specific reasons, but it comes with its own set of operational considerations.

Superior Adhesion and Durability

PVD coatings are known for their exceptional adhesion. The high-energy environment naturally cleans the substrate surface on an atomic level, and the energetic deposition promotes a strong bond between the coating and the object.

Ability to Coat High-Melting-Point Materials

Because PVD uses physical bombardment (sputtering) or focused energy (e-beams) for vaporization, it can easily create vapors from materials with extremely high melting points, such as tungsten and titanium, which are difficult to handle with other methods.

The Limitation: Line-of-Sight Deposition

The vaporized atoms travel in a straight line from the target to the substrate. This "line-of-sight" nature means it can be challenging to uniformly coat complex geometries with hidden surfaces. Sophisticated part rotation and fixturing are often required to ensure even coverage.

How to Apply This to Your Goal

Understanding the fundamentals helps you determine if PVD is the right approach for your application.

- If your primary focus is a pure, dense metallic film: Standard PVD through sputtering or evaporation is the direct path to achieving a high-quality coating.

- If your primary focus is extreme hardness, wear resistance, or a specific color: Reactive PVD is the necessary choice to form a robust ceramic compound coating like TiN or Al2O3.

- If you are coating a complex, three-dimensional part: You must plan for planetary rotation or multi-axis manipulation during the process to overcome line-of-sight limitations and achieve uniform coverage.

By grasping the principles of how a material is vaporized, transported, and deposited, you can effectively specify the right coating strategy for your desired outcome.

Summary Table:

| PVD Process Step | Key Action | Purpose |

|---|---|---|

| 1. Vaporization | Solid target material is converted to vapor via sputtering or evaporation. | Creates the source of coating atoms. |

| 2. Transportation | Vaporized atoms travel through a vacuum chamber. | Ensures pure, uncontaminated travel to the substrate. |

| 3. Deposition | Atoms condense on the substrate, forming a thin film. | Builds a dense, well-adhered coating layer by layer. |

Ready to enhance your products with high-performance PVD coatings?

KINTEK specializes in advanced lab equipment and consumables for materials science and surface engineering. Whether you are developing new coatings or optimizing your deposition process, our expertise and solutions can help you achieve superior adhesion, durability, and performance.

Contact our experts today to discuss how we can support your laboratory's specific PVD coating needs.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition