In essence, vacuum coating is a process for applying an exceptionally thin, durable film onto a surface by vaporizing a coating material and depositing it atom by atom within a high-vacuum chamber. This method, a form of Physical Vapor Deposition (PVD), creates robust layers that enhance a part's properties, such as hardness and wear resistance, without altering its fundamental dimensions.

At its heart, vacuum coating is about creating an empty space—a vacuum—so that individual atoms of a coating material can be "flown" from a source and precisely deposited onto a part, forming an ultra-thin, highly durable layer.

The Core Principle: Why a Vacuum is Essential

The entire process hinges on the vacuum environment. Its primary purpose is to remove all air and other gas molecules from the chamber.

Eliminating Interference

In a normal atmosphere, the air is dense with particles. Any attempt to "spray" atoms of a coating material would result in them colliding with air molecules, scattering them and preventing them from ever reaching the target surface cleanly.

Ensuring Purity and Adhesion

The vacuum creates an ultra-clean path from the coating source to the substrate. This prevents atmospheric gases like oxygen and nitrogen from reacting with the vaporized material, ensuring the deposited film is pure and bonds strongly to the surface.

The Deposition Process: From Solid to Film

While there are variations, the most common method is Physical Vapor Deposition (PVD). The process can be broken down into four distinct stages.

Stage 1: Preparation and Loading

Before the process begins, the component to be coated (the substrate) must be meticulously cleaned. Any microscopic contaminants like oils or oxides will prevent the coating from adhering properly. Once cleaned, parts are mounted on specialized fixtures and placed inside the vacuum chamber.

Stage 2: Creating the Vacuum

The chamber is sealed, and a series of pumps remove the air, creating a sub-atmospheric pressure environment. This "pump-down" phase is critical and sets the stage for a successful coating.

Stage 3: Vaporization of the Coating Material

A solid source material—often a metal or ceramic—is converted into a vapor. This is typically achieved in one of two ways:

- Thermal Evaporation: The source material is heated until it boils and evaporates, releasing a cloud of atoms.

- Sputtering: The source material (called a "target") is bombarded with high-energy ions (usually of an inert gas like argon). This bombardment acts like a microscopic sandblaster, knocking individual atoms off the target.

Stage 4: Deposition and Film Growth

The vaporized atoms travel in a straight line through the vacuum chamber and strike the substrate. Upon impact, they condense back into a solid state, forming a thin, dense, and highly uniform film. This layer is built up atom by atom, resulting in coatings that can be as thin as a few nanometers or up to several microns (typically 0.25 to 10 microns).

Understanding the Trade-offs

Vacuum coating is a powerful technology, but it's important to understand its specific characteristics and limitations.

Precision vs. Complexity

The process allows for incredible control over film thickness and uniformity. However, it requires significant investment in specialized equipment, strict process controls, and a high degree of technical expertise to run effectively.

Thin Films Only

Vacuum deposition is designed exclusively for creating very thin films. It is not a suitable method for applying thick, heavy-duty protective layers that you might achieve with processes like galvanizing or conventional painting.

Line-of-Sight Deposition

Because the vaporized atoms travel in straight lines, the process is "line-of-sight." Areas of a complex part that are shadowed or hidden may not receive an even coating without sophisticated part rotation and fixturing.

Making the Right Choice for Your Goal

To determine if vacuum coating is the correct approach, consider your primary objective.

- If your primary focus is extreme hardness and wear resistance: PVD coatings like Titanium Nitride (TiN) or Diamond-Like Carbon (DLC) are an industry standard for cutting tools, engine components, and medical implants.

- If your primary focus is a thin, decorative, yet durable finish: Sputtered coatings are used to create the metallic finishes on everything from automotive trim to consumer electronics and faucets.

- If your primary focus is optical or electrical properties: Vacuum deposition is used to create anti-reflective coatings on lenses and conductive layers in semiconductor manufacturing.

By understanding its principles, you can effectively leverage vacuum coating to achieve surface properties that are otherwise impossible.

Summary Table:

| Stage | Process | Key Action |

|---|---|---|

| 1 | Preparation | Meticulous cleaning and loading of substrate |

| 2 | Vacuum Creation | Removal of air to create sub-atmospheric pressure |

| 3 | Vaporization | Coating material vaporized via thermal evaporation or sputtering |

| 4 | Deposition | Atoms travel and condense on substrate, building film atom by atom |

Ready to enhance your components with precision vacuum coating? KINTEK specializes in advanced lab equipment and consumables for PVD processes, helping laboratories achieve superior surface properties for cutting tools, medical implants, and decorative finishes. Contact our experts today to discuss how our vacuum coating solutions can improve your product's durability and performance!

Visual Guide

Related Products

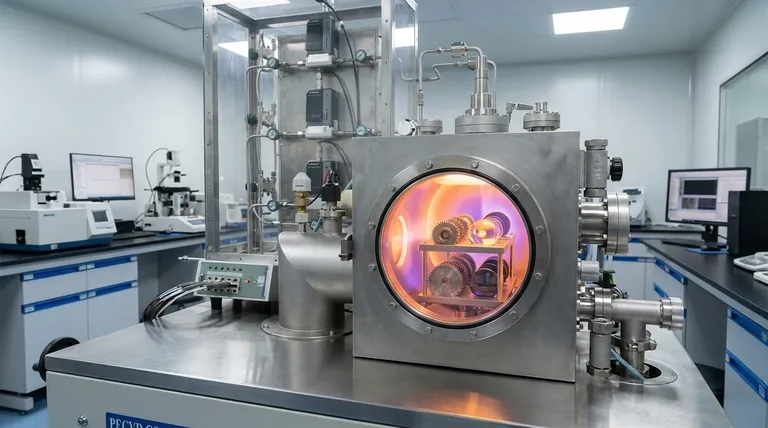

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings