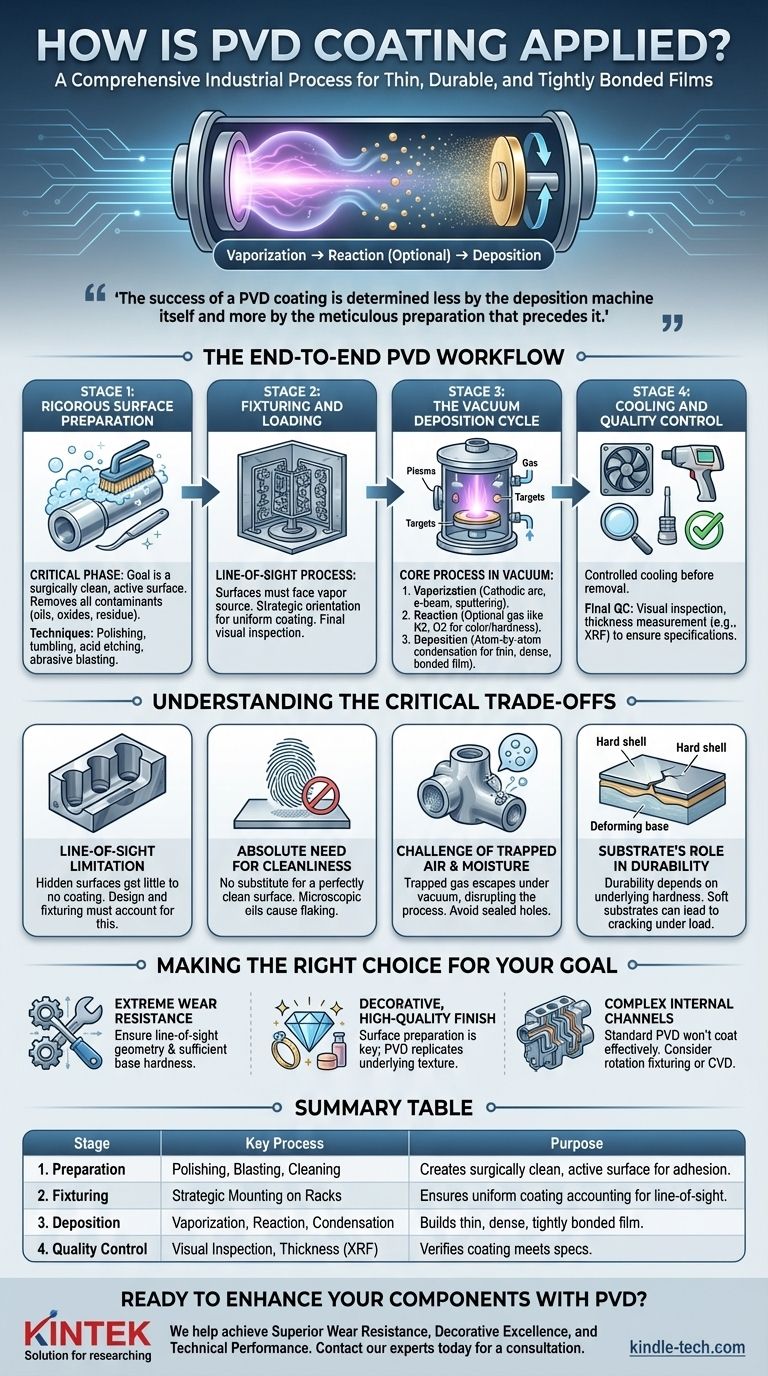

Applying a PVD coating is a comprehensive industrial process where a part undergoes rigorous cleaning and preparation before being placed in a vacuum chamber. Inside the chamber, a solid coating material is vaporized, sometimes reacted with specific gases to achieve desired properties, and then deposited atom-by-atom onto the part's surface to form a thin, durable, and tightly bonded film.

The success of a PVD coating is determined less by the deposition machine itself and more by the meticulous preparation that precedes it. The process is a holistic workflow where surface cleanliness and part preparation are paramount for achieving a high-quality, adherent finish.

The End-to-End PVD Workflow

The application of a PVD coating is not a single action but a sequence of carefully controlled stages. Each step builds upon the last, and a failure at any stage can compromise the final result.

Stage 1: Rigorous Surface Preparation

This is the most critical phase for ensuring the coating will adhere properly. The goal is to create a surgically clean, active surface.

Any contaminants, such as oils, grease, oxides, or residue from previous manufacturing steps (like EDM recast), must be completely removed.

Common preparation techniques include polishing, tumbling, acid etching, and abrasive blasting with sand or glass beads. The chosen method depends on the base material and the desired final surface finish.

Stage 2: Fixturing and Loading

Parts are not simply placed in the coating chamber; they are mounted on specialized fixtures.

This fixturing is crucial because PVD is a line-of-sight process. Surfaces must be strategically oriented to face the vapor source to receive a uniform coating.

Before the chamber is sealed, a final visual inspection ensures parts are clean and correctly positioned.

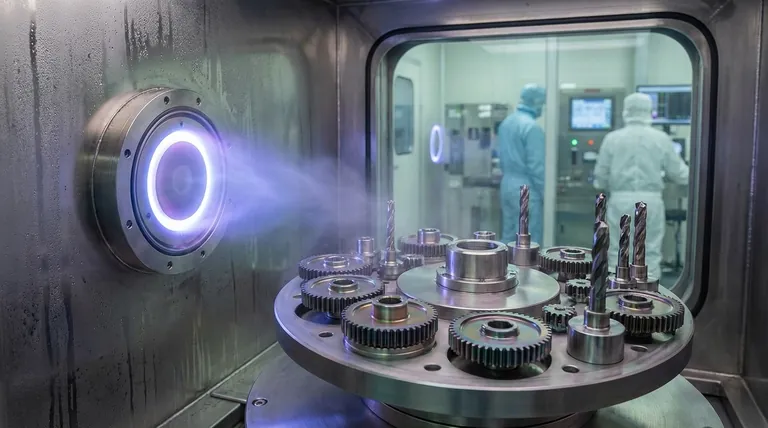

Stage 3: The Vacuum Deposition Cycle

This is the core of the PVD process, occurring entirely within a high-vacuum chamber. The vacuum environment is essential to prevent the vaporized coating material from reacting with air. This stage has three key actions.

Vaporization

The solid coating material, known as the "target," is converted into a vapor. This is accomplished using high-energy methods such as a cathodic arc (creating a plasma arc that vaporizes the target), electron-beam heating, or ion bombardment (sputtering).

Reaction (Optional)

For many advanced coatings, a reactive gas like nitrogen, oxygen, or methane is introduced into the chamber. This gas reacts with the metal vapor to form a new ceramic or metal-ceramic compound on the part's surface.

This step is what determines key properties like color (e.g., titanium nitride is gold, zirconium nitride is brass-colored) and hardness.

Deposition

The vaporized material travels through the vacuum chamber and condenses on the surfaces of the cooler parts.

This deposition occurs atom by atom, building a very thin (typically a few microns), extremely dense, and well-bonded film that is nearly impossible to remove through normal use.

Stage 4: Cooling and Quality Control

After the deposition cycle is complete, the parts must cool down before being removed from the chamber.

Once unloaded, the parts undergo final quality control. This includes visual inspection for cosmetic defects and, often, thickness measurement using techniques like X-ray fluorescence (XRF) to ensure the coating meets specifications.

Understanding the Critical Trade-offs

While powerful, the PVD process has specific constraints that must be understood to ensure a successful outcome. Misunderstanding these limitations is a common source of coating failure.

The "Line-of-Sight" Limitation

The coating material travels in a straight line from the source to the part. Any surface that is hidden or shadowed, such as the inside of a deep, narrow bore, will receive little to no coating. Part design and fixturing must account for this.

The Absolute Need for Cleanliness

There is no substitute for a perfectly clean surface. Even a microscopic layer of oil from a fingerprint can prevent the coating from bonding, leading to flaking or poor performance. The pre-treatment stage is non-negotiable.

The Challenge of Trapped Air and Moisture

Complex parts with tightly sealed tapped holes or overlapping seams can trap small amounts of air or moisture. When the chamber is put under vacuum, this trapped gas can escape and disrupt the coating process, causing a defect. Parts should be designed to eliminate such features where possible.

The Substrate's Role in Durability

A PVD coating is a very thin, hard shell. While it provides excellent wear resistance, its overall durability is dependent on the hardness of the underlying material. Applying a hard coating to a soft substrate can result in cracking or damage if the part deforms under load.

Making the Right Choice for Your Goal

To determine if PVD is the correct process for your application, consider your primary objective.

- If your primary focus is extreme wear resistance: Ensure your part’s geometry allows for line-of-sight application and that the base material is sufficiently hard to support the thin film under operational stress.

- If your primary focus is a decorative, high-quality finish: Your most critical investment will be in the surface preparation. The PVD coating will perfectly replicate the texture of the underlying surface, meaning a polished part will result in a polished coating.

- If your part has complex internal channels or blind holes: You must recognize that standard PVD will not coat these areas effectively and either design specific fixturing for rotation or consider alternative technologies like Chemical Vapor Deposition (CVD).

Ultimately, a successful PVD application is the result of designing for the entire process, not just for the final part.

Summary Table:

| Stage | Key Process | Purpose |

|---|---|---|

| 1. Preparation | Polishing, Blasting, Chemical Cleaning | Creates a surgically clean, active surface for optimal adhesion. |

| 2. Fixturing | Strategic Mounting on Racks | Ensures uniform coating by accounting for the line-of-sight nature of PVD. |

| 3. Deposition | Vaporization, Reaction (Optional), Atom-by-Atom Condensation | Builds a thin, dense, and tightly bonded film on the part surface. |

| 4. Quality Control | Visual Inspection, Thickness Measurement (XRF) | Verifies the coating meets specifications for performance and appearance. |

Ready to enhance your components with a high-performance PVD coating?

At KINTEK, we specialize in precision lab equipment and consumables for surface treatment applications. Our expertise ensures your parts receive the meticulous preparation and controlled deposition necessary for a flawless, durable finish.

We help our laboratory and manufacturing customers achieve:

- Superior Wear Resistance: Extend the life of cutting tools, molds, and critical components.

- Decorative Excellence: Create vibrant, tarnish-resistant finishes for consumer goods and medical devices.

- Technical Performance: Apply coatings with specific properties like low friction or chemical inertness.

Let's discuss how PVD coating can solve your specific challenge. Contact our experts today for a consultation.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is PECVD silicon deposition? Achieve Low-Temperature, High-Quality Thin Films

- What is meant by vapor deposition? A Guide to Atomic-Level Coating Technology

- What is plasma enhanced chemical vapor deposition? Achieve Low-Temperature, High-Quality Thin Films

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method

- What is plasma in CVD process? Lowering Deposition Temperatures for Heat-Sensitive Materials