In ideal conditions with proper regeneration, a molecular sieve's lifespan is not measured in time but in cycles. High-quality sieves can last for several years, enduring hundreds or even thousands of regeneration cycles. However, their functional life is ultimately determined by the operating conditions they are exposed to and the presence of contaminants that can cause irreversible damage.

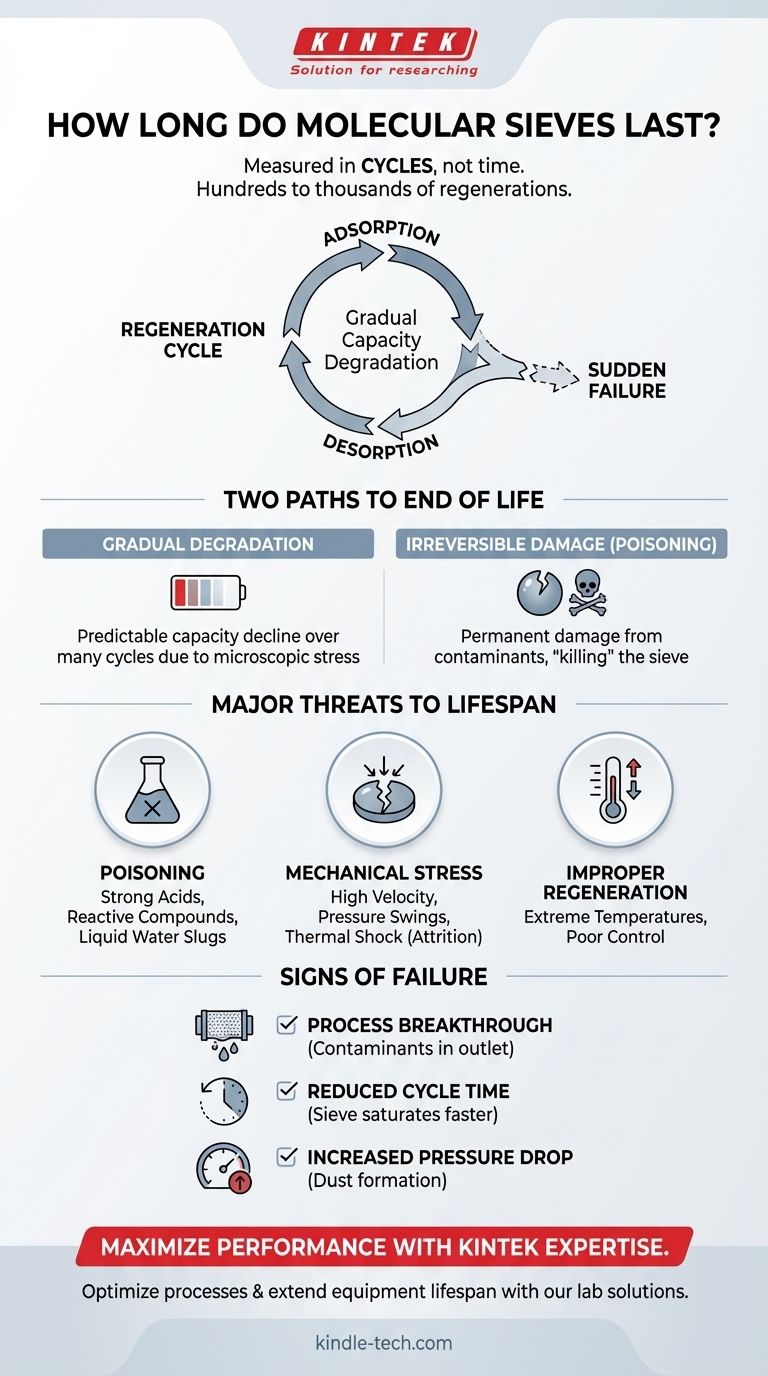

The core principle to understand is that molecular sieves do not "expire" like a perishable good. Instead, their capacity gradually degrades with each regeneration cycle, and their life is abruptly ended by contamination or physical damage.

What Determines a Molecular Sieve's Lifespan?

The longevity of a molecular sieve is a function of its environment and handling, not a fixed calendar date. Think of it less like a battery with a finite charge and more like a high-performance filter that can be repeatedly cleaned.

The Central Role of Regeneration

Molecular sieves work by adsorption, physically trapping molecules like water within their porous crystalline structure. They are not consumed in this process.

Regeneration is the process of heating the sieve (Thermal Swing Adsorption, or TSA) or reducing the pressure (Pressure Swing Adsorption, or PSA) to release the trapped molecules. This "resets" the sieve, making it ready for another cycle. The ability to be regenerated is what gives them their long life.

Gradual Degradation vs. Sudden Failure

A sieve's life typically ends in one of two ways:

- Gradual Loss of Capacity: Each regeneration cycle, especially high-temperature thermal ones, causes microscopic stress to the sieve's crystalline structure. Over hundreds or thousands of cycles, this leads to a slow, predictable decline in its ability to adsorb.

- Irreversible Damage (Poisoning): This is the more common cause of premature failure. Certain substances can permanently damage or block the sieve's pores, effectively "killing" it.

Understanding the Trade-offs and Causes of Failure

Properly managing your sieves means understanding the threats that shorten their lifespan. Avoiding these pitfalls is the single most effective way to maximize your investment.

Irreversible Poisoning

This is the fastest way to destroy a molecular sieve. Contaminants bond to the sieve material or clog its pores in a way that regeneration cannot reverse.

Key poisons include:

- Strong Acids: These chemically attack and destroy the alumino-silicate crystal structure of the zeolite.

- Reactive Compounds: Olefins, dienes, and other polymerizable molecules can form long chains (coke) inside the sieve pores, especially at high regeneration temperatures. This physically blocks access to the adsorption sites.

- Liquid Water Slugs: Allowing liquid water to enter a hot sieve bed causes rapid, violent steam release. This process, known as hydrothermal damage, can permanently alter and damage the crystal structure.

Mechanical Degradation (Attrition)

Sieves are brittle. Physical stress can cause them to break down into dust.

This is often caused by:

- High Gas Velocity: Can fluidize the bed, causing particles to collide and fracture.

- Rapid Pressure Swings: Can cause particles to shift and grind against one another.

- Thermal Shock: Rapid temperature changes can cause beads or pellets to crack.

This dust not only represents a loss of active material but also increases the pressure drop across the system, reducing overall efficiency.

Recognizing a Failed Sieve

You will know it is time for a replacement when you observe one or more of the following signs:

- Process Breakthrough: The most critical indicator. The molecule you are trying to remove (e.g., water) starts appearing in the outlet stream before the end of a normal cycle. This means the sieve is saturated and no longer performing its function.

- Reduced Cycle Time: As the sieve's capacity diminishes, the time it takes to become saturated gets progressively shorter.

- Increased Pressure Drop: A significant increase in the pressure required to push gas or liquid through the sieve bed often indicates the formation of dust from attrition.

- Lab Analysis: The most precise method is to take a sample of the sieve and have its adsorption capacity professionally measured in a laboratory.

Making the Right Choice for Your Goal

Your approach to managing sieve lifespan depends heavily on your application.

- If your primary focus is a large industrial drying or purification process: Your priority is protecting the sieve bed from poisons and optimizing regeneration to minimize thermal and mechanical stress.

- If your primary focus is drying solvents in a laboratory: Regeneration is feasible in a lab oven, but replacement is often cheap and simple. The main goal is to avoid introducing water and other contaminants that would exhaust the sieve prematurely.

- If your primary focus is a sealed unit like insulated glass windows: The sieve is designed to last the lifetime of the unit. Its failure is synonymous with the failure of the window seal, and the entire unit must be replaced.

Ultimately, understanding that molecular sieves are a reusable asset to be protected, rather than a disposable consumable, is the key to achieving a long and effective service life.

Summary Table:

| Factor | Impact on Lifespan | Key Considerations |

|---|---|---|

| Regeneration Cycles | Gradual capacity loss over hundreds/thousands of cycles | Proper temperature control during thermal regeneration |

| Contamination | Can cause irreversible damage (poisoning) | Avoid acids, reactive compounds, liquid water slugs |

| Mechanical Stress | Leads to attrition and dust formation | Control gas velocity, pressure swings, thermal shock |

| Application Type | Varies from years (industrial) to lifetime (sealed units) | Match maintenance strategy to specific use case |

Maximize your molecular sieve performance with KINTEK's expertise!

As specialists in lab equipment and consumables, we understand the critical role proper sieve management plays in your laboratory's efficiency and cost-effectiveness. Whether you need high-quality molecular sieves, regeneration guidance, or complete purification solutions, our team can help you optimize your processes and extend equipment lifespan.

Contact us today to discuss your specific application needs and discover how KINTEK's products and expertise can enhance your laboratory's drying and purification workflows.

Visual Guide

Related Products

People Also Ask

- Does higher heat capacity mean higher melting point? Unraveling the Critical Difference

- Why is Boron Nitride used in RRDE? Enhance Precision with Superior Insulating and Protective Material

- Why is Boron Nitride utilized as a coating for graphite molds? Protect Your Mo-Na Powder During Sintering

- What are the advantages and disadvantages of brazing? A Guide to Strong, Clean Metal Joining

- What is the function of a BN inner liner in a graphite mold during Flash Sintering? Master Precise Current Control