There is no single answer for the duration of a vacuum heat treatment cycle. The total time is highly dependent on the specific material, the size and thickness of the part, and the total mass of the load being processed. A complete cycle can range from just a few hours for small, simple components to well over 24 hours for very large or complex parts.

The crucial takeaway is that a vacuum heat treatment cycle is not a fixed, off-the-shelf process. It is a precisely engineered thermal profile tailored to the material, geometry, and desired final properties of the workpiece.

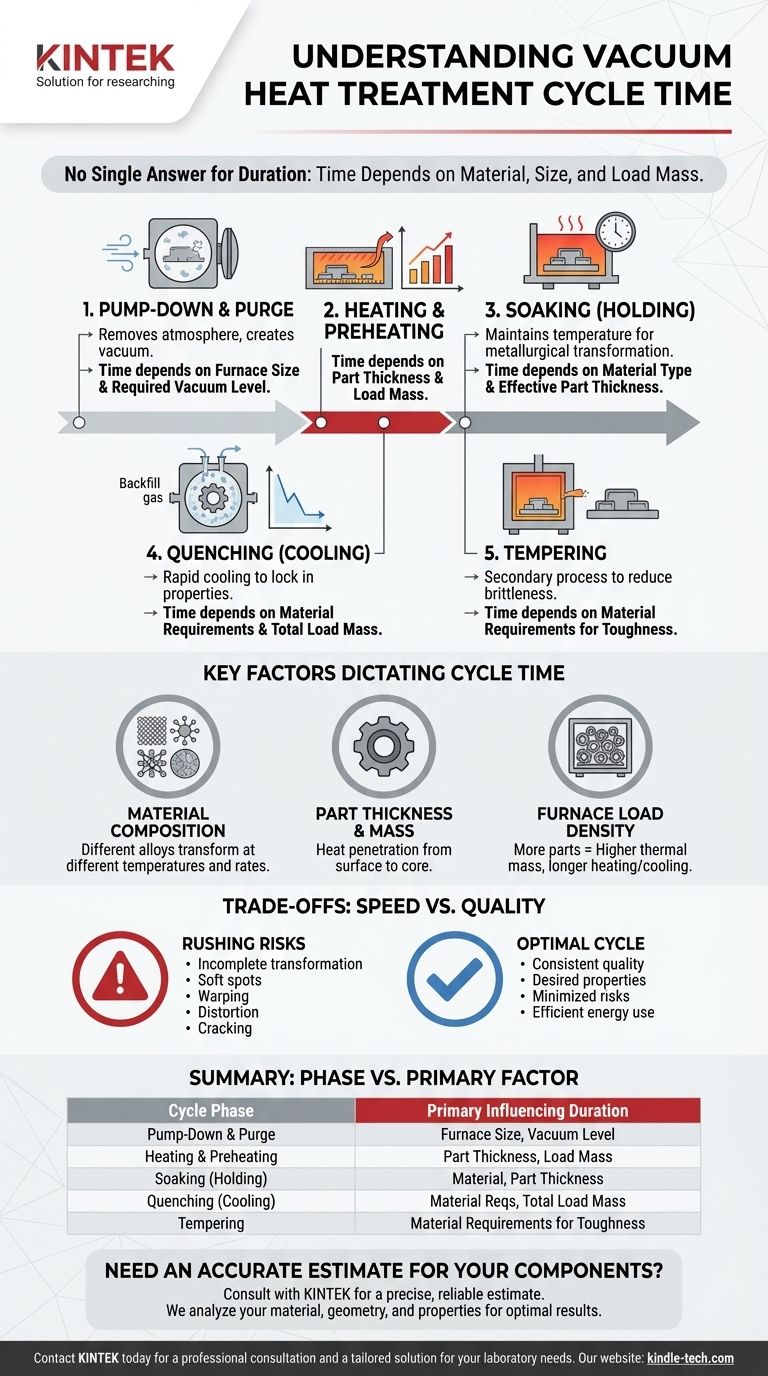

Deconstructing the Vacuum Heat Treatment Cycle

To understand the total time, you must first understand the individual stages. Each phase has a distinct purpose and its duration is governed by different physical principles.

The Pump-Down and Purge Phase

Before any heating begins, the furnace chamber must have the atmosphere removed to create a vacuum. This phase involves powerful pumps evacuating air and, often, backfilling the chamber with an inert gas like nitrogen or argon to purge any remaining oxygen before evacuating again.

The time required depends on the size of the furnace and the required vacuum level. Larger chambers naturally take longer to evacuate.

The Heating and Preheating Phase

This is the stage where the furnace temperature is ramped up to the target processing temperature. For many materials, this is not a single, direct ramp.

The cycle often includes one or more preheating steps, where the temperature is raised to an intermediate point and held. This allows the temperature to equalize throughout the parts, especially those with varying thicknesses, preventing thermal shock and distortion.

The Soaking (Holding) Phase

Once the material reaches the final target temperature, it is "soaked" or held at that temperature for a specific period. This is the most critical phase for achieving the desired metallurgical transformation.

The holding time is a calculated value, not a guess. As your reference notes, it is determined by the effective thickness of the workpiece. The goal is to ensure the core of the thickest section reaches the target temperature and undergoes the complete metallurgical change.

The Quenching (Cooling) Phase

After soaking, the parts must be cooled at a specific rate to lock in the desired properties, such as hardness. In a vacuum furnace, this is typically done by backfilling the chamber with high-pressure inert gas (like nitrogen or helium) and circulating it with a powerful fan.

The cooling rate is determined by the material's requirements. Some tool steels need an extremely fast quench, while other alloys may require a slower, more controlled cool to prevent cracking. The total mass of the load significantly impacts the time needed to extract heat.

The Tempering Phase

For many hardening processes, a subsequent tempering cycle is required. This is a secondary, lower-temperature heat treatment that reduces brittleness and increases the toughness of the hardened material.

Tempering can add several more hours to the overall process time and is often performed in a separate furnace to improve workflow efficiency.

Key Factors That Dictate Cycle Time

Three primary variables control the length of every stage in the heat treatment cycle.

Material Composition

Different alloys transform at different temperatures and rates. A high-alloy tool steel requires a very different temperature profile and soaking time than a simple low-alloy steel or a nickel-based superalloy.

Part Thickness and Mass

This is the single most significant factor. Heat must penetrate from the surface to the core of the part. The thicker the part's cross-section, the longer the heating and soaking time required for the core to reach the correct temperature.

Furnace Load Density

A furnace packed with many parts has a much higher thermal mass than one with a single part. It simply takes more energy and time to heat the entire load uniformly and to cool it down during the quench.

Understanding the Trade-offs: Speed vs. Quality

It can be tempting to try and shorten cycle times to increase throughput, but this comes with significant risks.

The Danger of Rushing the Process

Insufficient soaking time can result in an incomplete metallurgical transformation, leading to soft spots or inconsistent hardness. Heating or cooling too quickly can create internal stresses, causing parts to warp, distort, or even crack.

The Cost of an Overly Conservative Cycle

Conversely, excessively long cycles do not necessarily improve quality and lead to wasted resources. This increases energy consumption and ties up expensive furnace capacity, raising the overall cost of the treatment without adding value.

Estimating the Time for Your Specific Project

To get an accurate estimate, you must move from general questions to specific details. The best approach is to consult directly with a heat treatment professional, providing them with the necessary information.

- If your primary focus is a budgetary quote: Provide the material type, the overall dimensions, and the maximum cross-sectional thickness of the part.

- If your primary focus is process planning for a critical component: You will need to provide a detailed engineering drawing, the specific material grade, and the required final properties (e.g., hardness range, case depth).

- If your primary focus is optimizing a high-volume production run: Work with your heat treater to analyze the furnace load configuration and part orientation, as this can significantly impact cycle efficiency.

Ultimately, the duration of a vacuum heat treatment cycle is the time required to achieve the correct metallurgical properties reliably and repeatably.

Summary Table:

| Cycle Phase | Primary Factor Influencing Duration |

|---|---|

| Pump-Down & Purge | Furnace Chamber Size & Required Vacuum Level |

| Heating & Preheating | Part Thickness & Load Mass |

| Soaking (Holding) | Material Type & Effective Part Thickness |

| Quenching (Cooling) | Material Requirements & Total Load Mass |

| Tempering | Material Requirements for Toughness |

Need an accurate cycle time estimate for your specific components?

The duration of a vacuum heat treatment cycle is critical for your project planning and quality. Don't guess—get a precise, reliable estimate from the experts at KINTEK.

We specialize in providing lab equipment and consumables for precise thermal processing. By understanding your material, part geometry, and desired properties, we can help you determine the optimal cycle time to ensure superior results without costly delays or quality issues.

Contact KINTEK today for a professional consultation and a tailored solution for your laboratory needs.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- Can you get an electrical arc in vacuum? How High Voltage Creates Plasma in a Void

- What is the function of a high-temperature sintering furnace? Powering Refractory Synthesis and Structural Integrity

- Why is a high-temperature furnace required for the solution treatment of Cr-Ni-Ti stainless steel? Optimize Swaging.

- How do high-temperature furnaces facilitate the production of active carbon aerogels? Master Supercapacitor Fabrication

- What products are annealed? A Guide to Metals Requiring a Thermal 'Reset'

- What role do dynamic vacuum heat treatment furnaces play in enhancing Inconel 718? Unlock Superior Alloy Performance

- Where are vacuum furnaces used? Essential for High-Purity Heat Treatment in Critical Industries

- What pressure is hot isostatic press? Achieve Full Density & Superior Material Performance