The force of a hydraulic press is not a single, standard number. It varies dramatically depending on the machine's design and intended purpose, with its capability measured in tonnage. A press's force can range from just one ton for a small benchtop unit to many thousands of tons for massive industrial forging machines.

A hydraulic press has no default force value. Its power is a specific design rating called tonnage, which defines the maximum force it can exert. Understanding this rating is the key to grasping its capabilities.

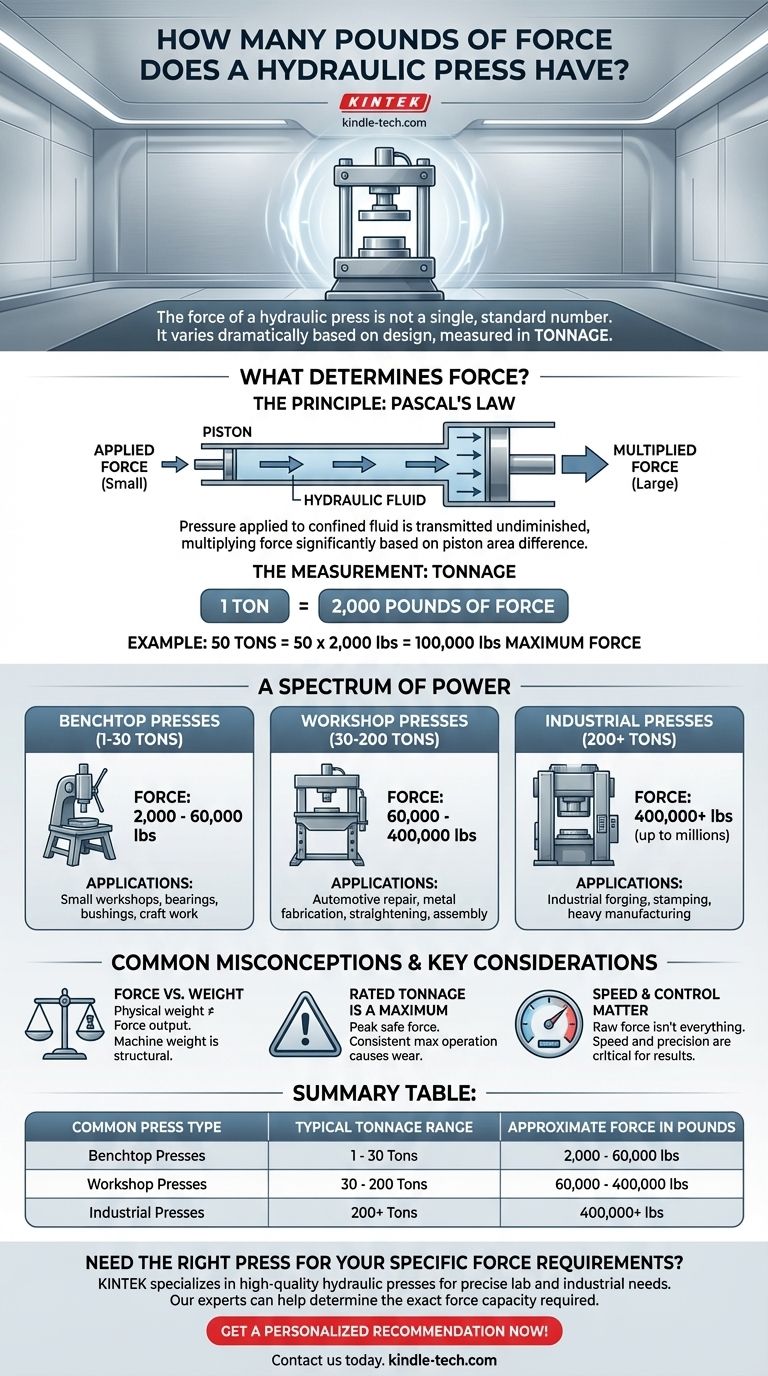

What Determines a Hydraulic Press's Force?

The immense power of a hydraulic press comes from a simple but powerful physics principle. Its force is not an arbitrary number but a direct result of its hydraulic system design.

The Principle: Pascal's Law

At its core, a hydraulic press operates on Pascal's Law. This principle states that pressure applied to a confined fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

In simple terms, a small amount of force applied to a small piston creates pressure in hydraulic fluid. This same pressure then acts on a much larger piston, multiplying the initial force significantly. The force multiplication is proportional to the difference in the pistons' surface areas.

The Measurement: Tonnage

The industry standard for rating a press's maximum force is tonnage. One ton of force is equal to 2,000 pounds of force.

When you see a press rated at "50 tons," it means the machine can exert a maximum continuous force of 100,000 pounds (50 tons x 2,000 lbs/ton) on the workpiece.

A Spectrum of Power

The required tonnage is dictated entirely by the application, leading to a vast range of machine sizes and capabilities.

- Benchtop Presses (1-30 Tons): These are common in small workshops for tasks like pressing bearings, bushings, or for small-scale craft work. They might generate between 2,000 and 60,000 pounds of force.

- Workshop Presses (30-200 Tons): Found in automotive repair and metal fabrication shops, these H-frame presses are used for straightening parts, heavy-duty pressing, and general assembly.

- Industrial Presses (200+ Tons): These massive machines are used for industrial forging, stamping car body panels, and other heavy manufacturing processes, with some capable of exerting tens of thousands of tons of force—tens of millions of pounds.

Common Misconceptions and Key Considerations

Simply knowing the tonnage doesn't tell the whole story. Understanding the context of that rating is critical for effective and safe operation.

Force vs. Weight

The physical weight of the press is completely unrelated to the force it can generate. A press that weighs 500 pounds might easily generate 50,000 pounds of force. The machine's weight is about structural integrity, not force output.

Rated Tonnage is a Maximum

The tonnage rating is the peak force the press is designed to handle safely. Consistently operating a press at its absolute maximum limit can lead to premature wear on its frame, seals, and hydraulic components.

Speed and Control Matter, Too

For many applications, raw force is not the only important factor. The speed at which the ram travels and the precision of the controls can be just as critical for achieving the desired result without damaging the workpiece.

Making the Right Choice for the Task

To determine how much force is needed, you must first define the job. The material type, its thickness, and the specific operation (bending, stamping, forging) all dictate the required tonnage.

- If your primary focus is small-scale hobby work or light automotive tasks: A 1 to 20-ton benchtop or A-frame press is more than sufficient.

- If your primary focus is general metal fabrication or a professional auto shop: A 50 to 100-ton H-frame press provides the versatility for a wide range of jobs.

- If your primary focus is heavy industrial manufacturing or forging: The required force must be calculated by engineers, often leading to custom-built presses rated for hundreds or thousands of tons.

Ultimately, the force of a hydraulic press is defined by its specific design, and choosing the correct one begins with a clear understanding of your application's demands.

Summary Table:

| Common Press Type | Typical Tonnage Range | Approximate Force in Pounds |

|---|---|---|

| Benchtop Presses | 1 - 30 Tons | 2,000 - 60,000 lbs |

| Workshop Presses | 30 - 200 Tons | 60,000 - 400,000 lbs |

| Industrial Presses | 200+ Tons | 400,000+ lbs |

Need the Right Press for Your Specific Force Requirements?

Whether you're in a small workshop or a large industrial facility, selecting the correct hydraulic press tonnage is critical for your project's success and safety. KINTEK specializes in providing high-quality lab equipment and consumables, including a range of hydraulic presses designed to meet precise laboratory and industrial needs.

Our experts can help you determine the exact force capacity required for your applications—from pressing bearings and bushings to heavy-duty metal fabrication. Contact us today to ensure you get a press that delivers the power, control, and durability your work demands.

Get a Personalized Recommendation Now!

Visual Guide

Related Products

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Double Plate Heating Press Mold for Lab

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

People Also Ask

- Which type of resins are used in compression molding? Thermosets vs. Thermoplastics

- What happens after the HPHT growth cycle is complete and what shapes can the resulting diamonds have? Expert Analysis

- What is a laboratory press? Achieve Precise Sample Preparation for Reliable Analysis

- How do you control pressure in a hydraulic system? Master Flow Resistance for Optimal Performance

- How do you measure the force of a press? Accurately Monitor Tonnage with Direct Load Cell Measurement

- What is the number one cause of failure in hydraulic systems? The Silent Killer of Your Equipment

- What is the heat generated in a hydraulic system can be absorbed by? Key Components for Thermal Management

- Why is my hydraulic press not holding pressure? Diagnose and Fix Common Leaks