At its core, a hydraulic hot press works by combining two fundamental principles: immense, controllable force generated by a hydraulic system and thermal energy from heated plates. This synergy allows the machine to precisely press, bond, or form materials. The hydraulic system uses an incompressible fluid, typically oil, to multiply a small initial force into a massive, uniform pressure, while the heated plates (platens) soften the workpiece or activate adhesives to achieve the desired outcome.

The machine's effectiveness stems from a simple physics principle—Pascal's Law—amplified by modern automation. It translates the power of a small pump into tons of uniform force, while a sophisticated control system manages heat and pressure to ensure consistent, high-quality results.

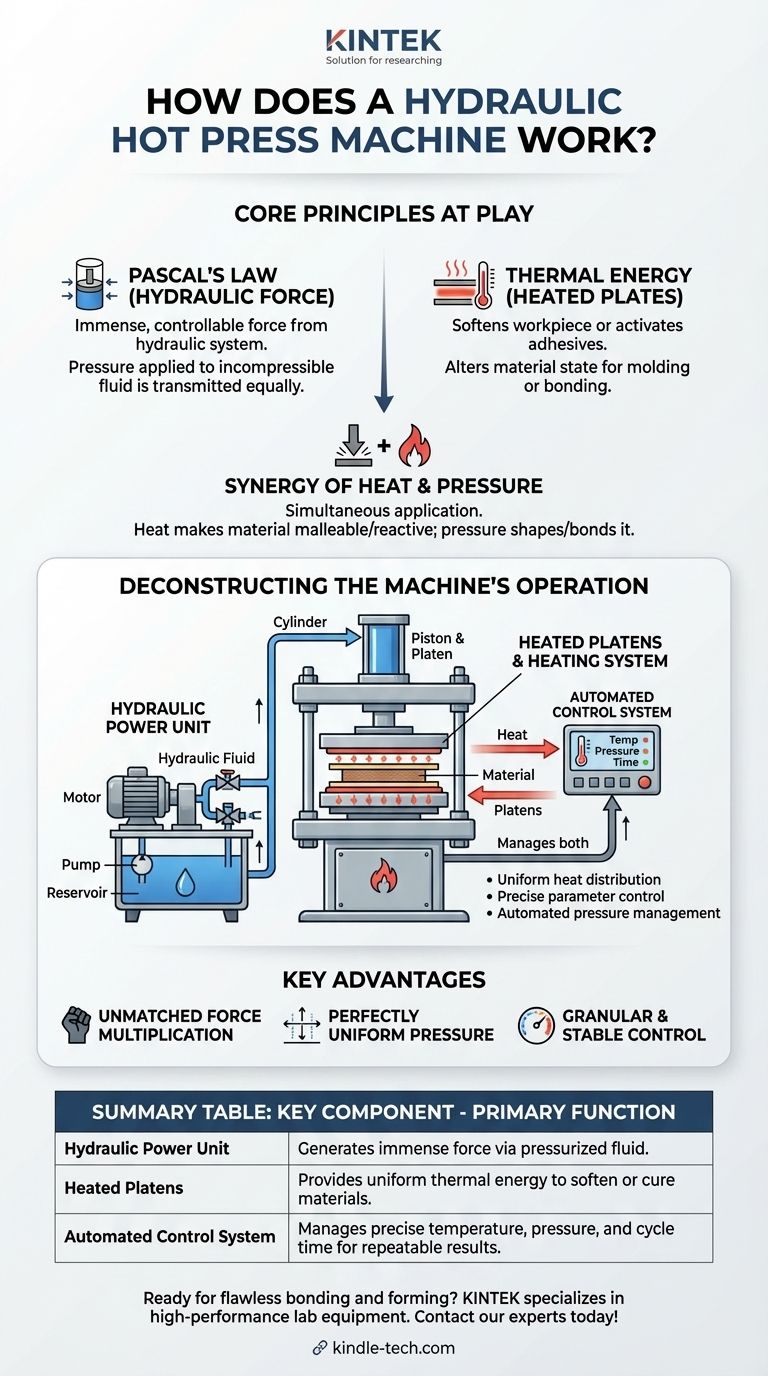

The Core Principles at Play

To truly understand the machine, you must first grasp the two scientific concepts that enable its operation. These principles work in tandem to manipulate materials with a high degree of precision.

Pascal's Law: The Engine of Force

The "hydraulic" part of the name refers to its power source, which is governed by Pascal's Law. This law states that pressure applied to a confined, incompressible fluid is transmitted equally throughout that fluid.

A hydraulic press exploits this by using a pump to apply pressure to hydraulic oil in a small cylinder. This pressure is then transferred to a much larger piston, multiplying the initial force significantly. This allows a relatively small motor to generate immense and highly controllable pressing force.

Thermal Energy: The Catalyst for Change

The "hot press" aspect refers to the machine's heated platens. These large, flat plates are typically heated by internal electrical elements or circulating thermal oil.

The purpose of the heat is to alter the state of the workpiece. It can soften plastics or composites to make them pliable for molding, or it can cure thermosetting resins and activate adhesives for permanent bonding, such as in laminating wood veneers.

The Synergy of Heat and Pressure

Neither heat nor pressure alone would be as effective. The machine applies both simultaneously for a specific purpose.

Heat makes the material malleable or chemically reactive. The immense, uniform pressure then forces the material into a new shape or ensures intimate, bubble-free contact between layers for a perfect bond.

Deconstructing the Machine's Operation

A hydraulic hot press is an integrated system where each component plays a critical role in achieving a precise and repeatable process.

The Hydraulic Power Unit

This is the heart of the machine. It consists of a motor, a pump, a reservoir for hydraulic fluid, and control valves. The pump forces the fluid into the main hydraulic cylinder, driving the piston and the attached platen.

The Heated Platens and Heating System

The platens are the work surfaces that transfer both heat and force to the material. An effective heating system, often using a series of precisely placed heating pipes or cartridges, is crucial for ensuring fast and, most importantly, even heat distribution across the entire surface.

The Automated Control System

Modern machines are managed by an advanced control panel. This system allows an operator to set precise parameters for temperature, pressure, and press time.

Crucially, it automates the process of pressurization, pressure-holding, and pressure replenishment. This ensures the workpiece is subjected to uniform pressure throughout the entire cycle, which is essential for preventing defects and guaranteeing product quality.

Key Advantages of the Hydraulic Design

The choice of a hydraulic system is deliberate, as it offers distinct advantages over mechanical or pneumatic alternatives, especially when heat is involved.

Unmatched Force Multiplication

As explained by Pascal's Law, hydraulic systems provide the most efficient way to generate the massive forces required for industrial pressing applications. This is accomplished with relatively compact and energy-efficient components.

Perfectly Uniform Pressure

A key benefit of using a fluid to transmit force is that it distributes pressure evenly across the entire face of the piston. This uniformity translates directly to the platen and the workpiece, eliminating weak spots and ensuring consistent quality, which is critical for laminating and molding.

Granular and Stable Control

Hydraulic systems allow for precise and stable control over the applied force. The system can hold a specific pressure for an extended period without fluctuation, and the control system can make micro-adjustments as needed. This level of control is vital for working with sensitive materials.

Applying This to Your Goals

Understanding how the machine works allows you to leverage its capabilities for specific manufacturing outcomes. Your focus will determine which aspect of its function is most critical.

- If your primary focus is bonding materials (e.g., laminating plywood): The key is the system's ability to apply uniform heat to activate the adhesive and uniform pressure to ensure a flawless, void-free bond across a large surface.

- If your primary focus is forming materials (e.g., molding composites): The critical function is the precise control over temperature to achieve material plasticity, combined with the immense hydraulic force needed to press the material into a complex mold with perfect accuracy.

- If your primary focus is consistent production quality: The most important feature is the automated control system, which guarantees that every cycle has the exact same temperature and pressure profile, delivering repeatable results with minimal operator intervention.

By mastering the interplay of hydraulic force and thermal energy, the hot press provides unparalleled control and precision in modern manufacturing.

Summary Table:

| Key Component | Primary Function |

|---|---|

| Hydraulic Power Unit | Generates immense, controllable force via pressurized fluid. |

| Heated Platens | Provides uniform thermal energy to soften or cure materials. |

| Automated Control System | Manages precise temperature, pressure, and cycle time for repeatable results. |

Ready to achieve flawless material bonding and forming in your lab? KINTEK specializes in high-performance lab equipment, including hydraulic hot presses designed for precision and reliability. Our machines deliver the uniform heat and pressure your projects demand. Contact our experts today to find the perfect solution for your laboratory needs!

Visual Guide

Related Products

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Double Plate Heating Press Mold for Lab

People Also Ask

- Why is hot pressing sintering technology preferred? Achieve Near-Theoretical Density in Electrical Contacts

- Why is precise temperature control within the supercooled liquid region necessary when using a hot press? (Full Guide)

- What is the function of a laboratory high-temperature hydraulic press? Optimize MEA Fabrication for HCl Electrolysis

- What products are made from hot forging? Discover High-Strength Components for Critical Applications

- What are the advantages of Cold Sintering Process equipment? Revolutionize Ceramic/Polymer Composites Under 300°C

- How is a high-precision programmable temperature-controlled heating stage utilized in the real-time study of copper oxidation?

- What is the purpose of a heated base with vacuum suction? Improve MEA Coating Precision and Catalyst Performance

- What is the primary function of a laboratory hot press? Optimize Thallium Bromide (TlBr) Crystal Growth